Universal rotating fluid pipeline

A fluid pipeline, universal technology, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, adjustable connection, etc. Simple and convenient installation and debugging, the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

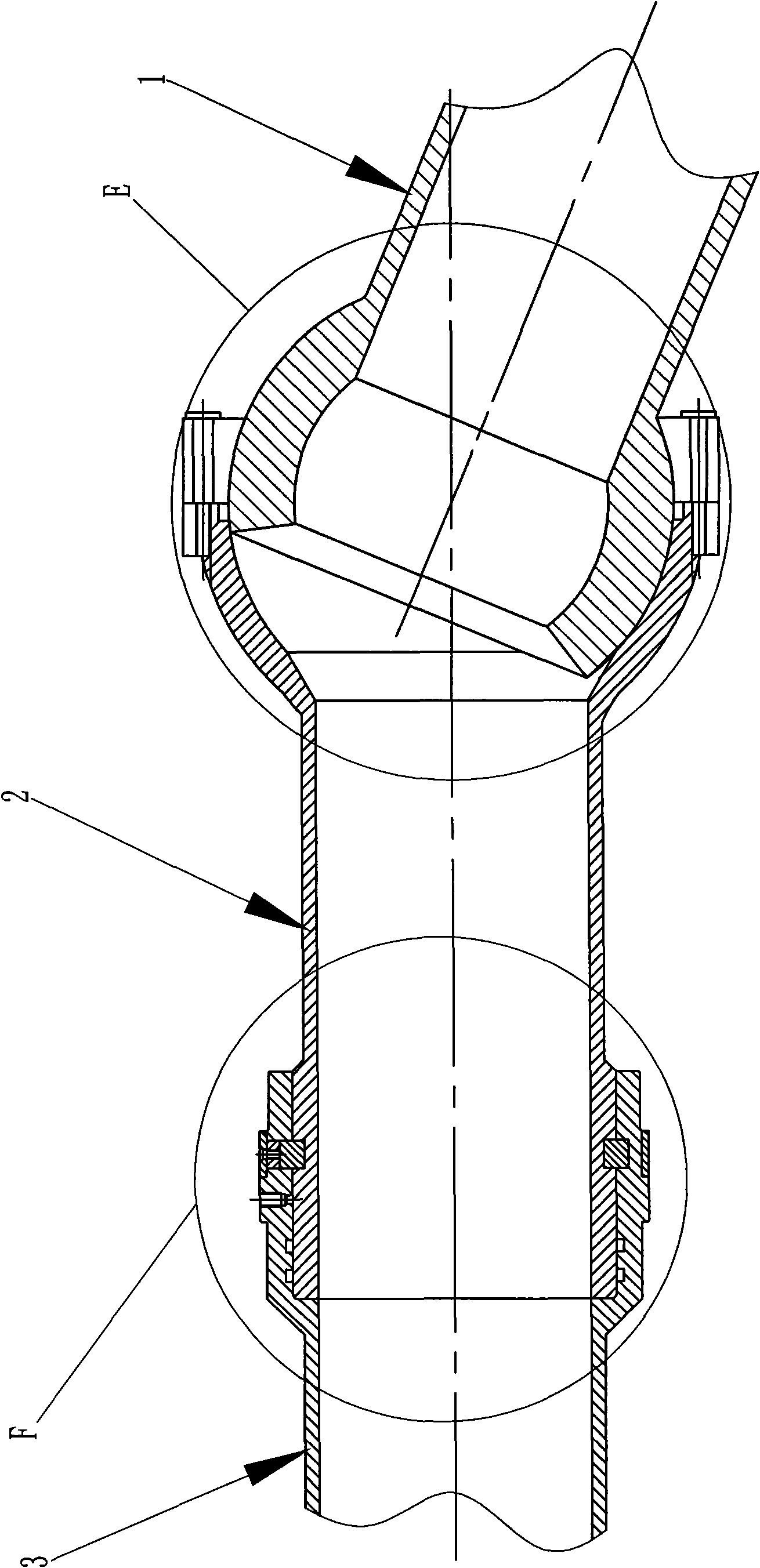

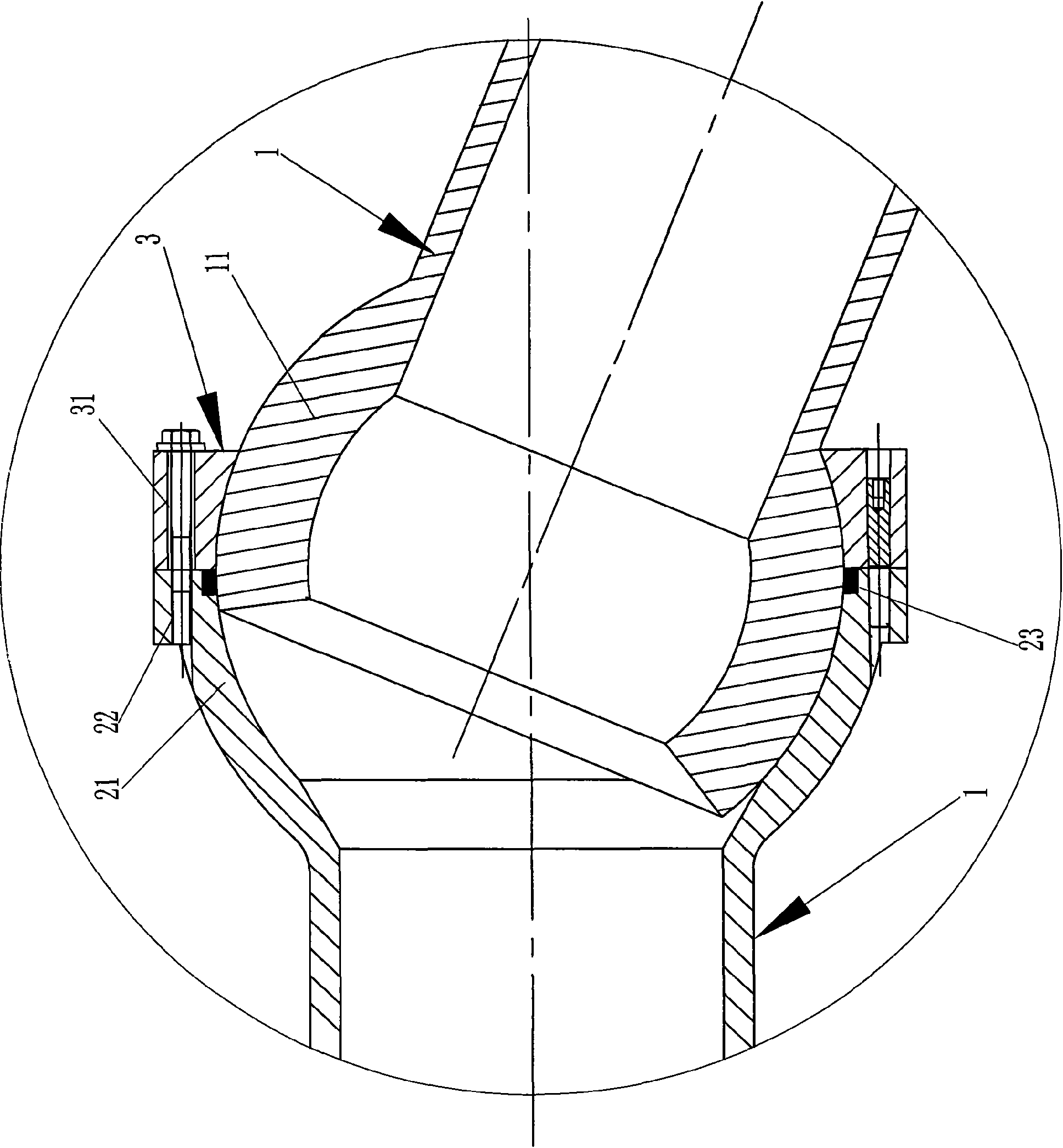

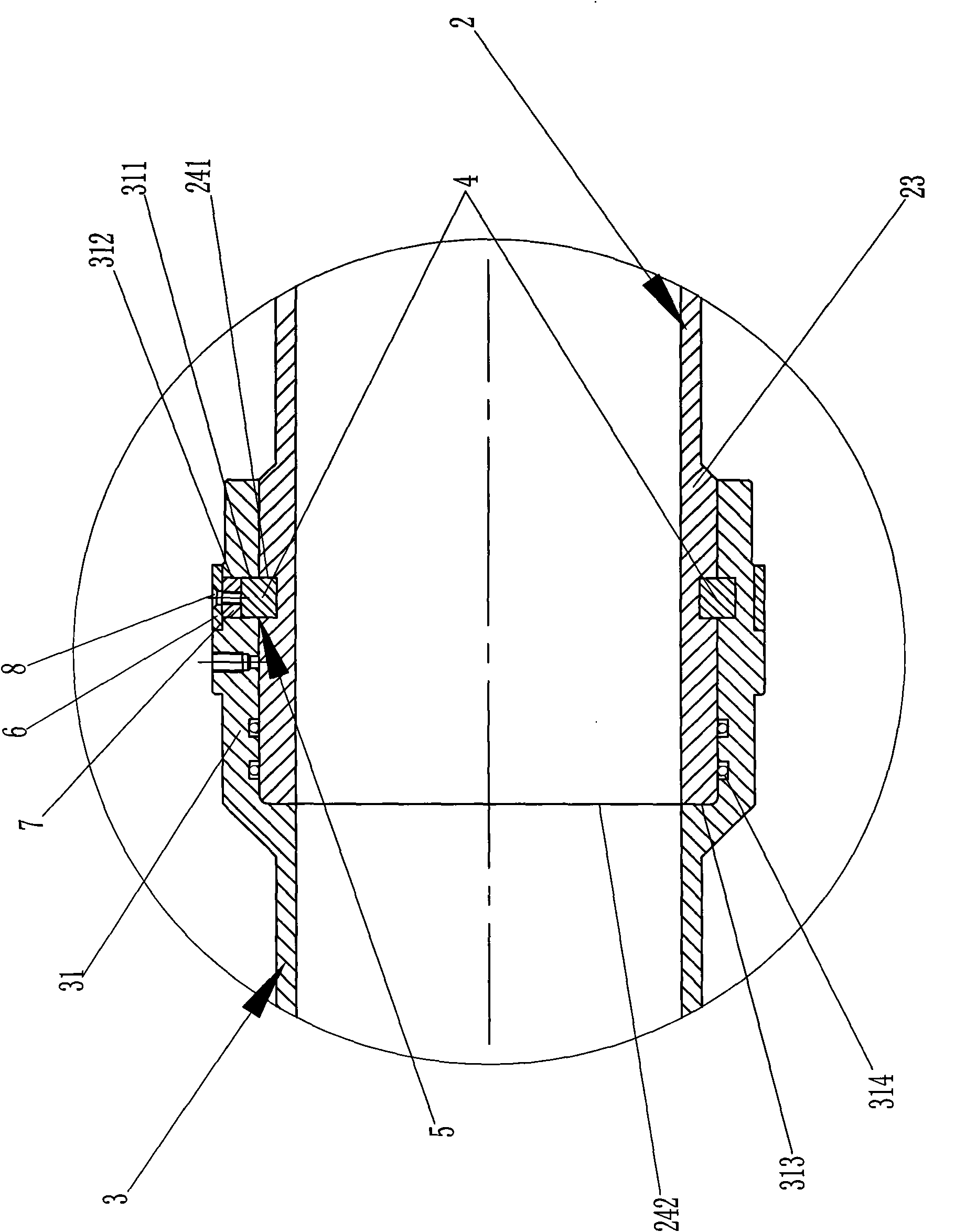

[0014] Such as figure 1 As shown, a specific embodiment of the present invention is a universally rotating fluid conduit comprising a first tubular member 1, a second tubular member 2 and a third tubular member 3, each tubular member being connected to be rotatable relative to each other Universal movement, such as figure 2 As shown, the first tubular member 1 and the second tubular member 2 are connected by a rotatable universal ball joint structure, and the connecting end of the second tubular member 2 forms a hollow outer spherical portion 21, and the adjacent second tubular member 1 The connecting end forms a hollow inner spherical part 11 connected with the outer spherical part 21 of the second tubular member 2, the inner spherical part 11 is rotatably sleeved in the outer spherical part 21, corresponding to the second tubular member 2 and the second tubular member 1, an annular outer casing 3 is sleeved on the outer peripheral wall of the inner spherical part 11 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com