Method and device for supporting and fixing filter element of precision filter by using upper seal head

A precision filter and supporter technology, which is applied to fixed filter element filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of inability to guarantee the sealing effect, high processing cost, waste of metal materials, etc., and achieve weight reduction , cost reduction, and the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

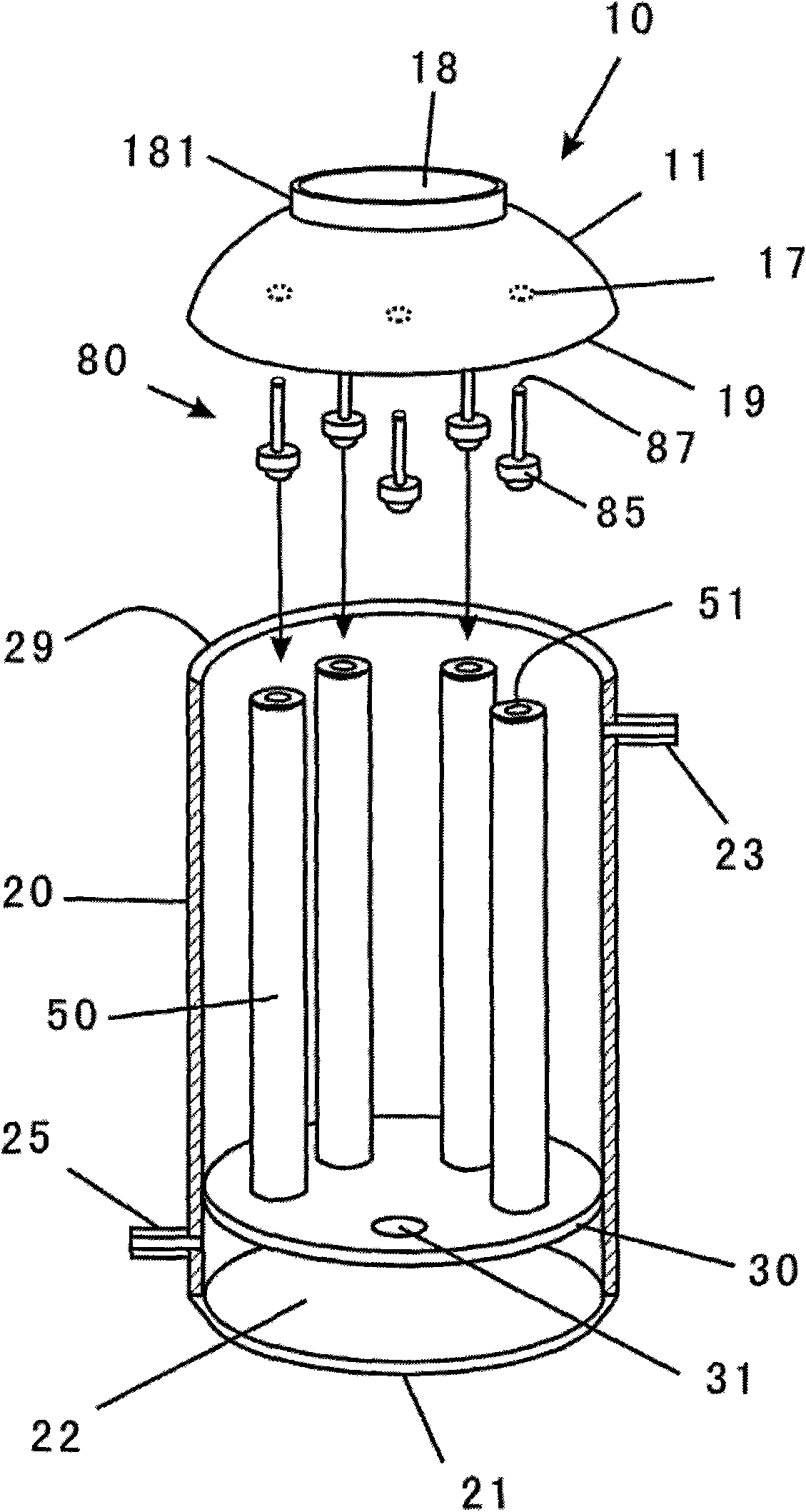

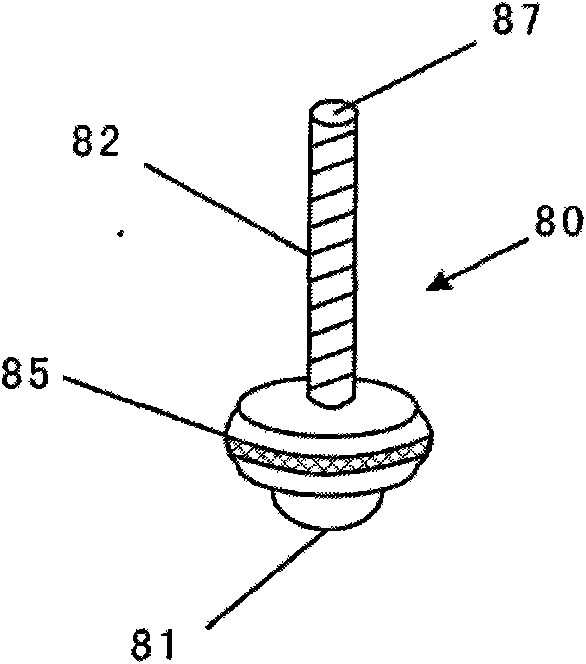

[0067] In the second embodiment of the present invention: during the elastic mechanism, the slide bar seat welding point 88 of the slide bar seat 86 and figure 2 The connecting point 17 of the filter head supporter in the shown upper head housing 11 is welded. If the length of the slide bar 84 is long enough at this time, it is long enough to extend to the outside of the upper head housing 11 (at this time on the upper head A hole is opened at the corresponding position of the housing 11), then, the operator pulls the extension of the slide rod 84 to compress the spring 83, which facilitates the installation of the filter element 50. At this time, the matching slide rod 84 sealing device is arranged on the upper head shell body 11 outside.

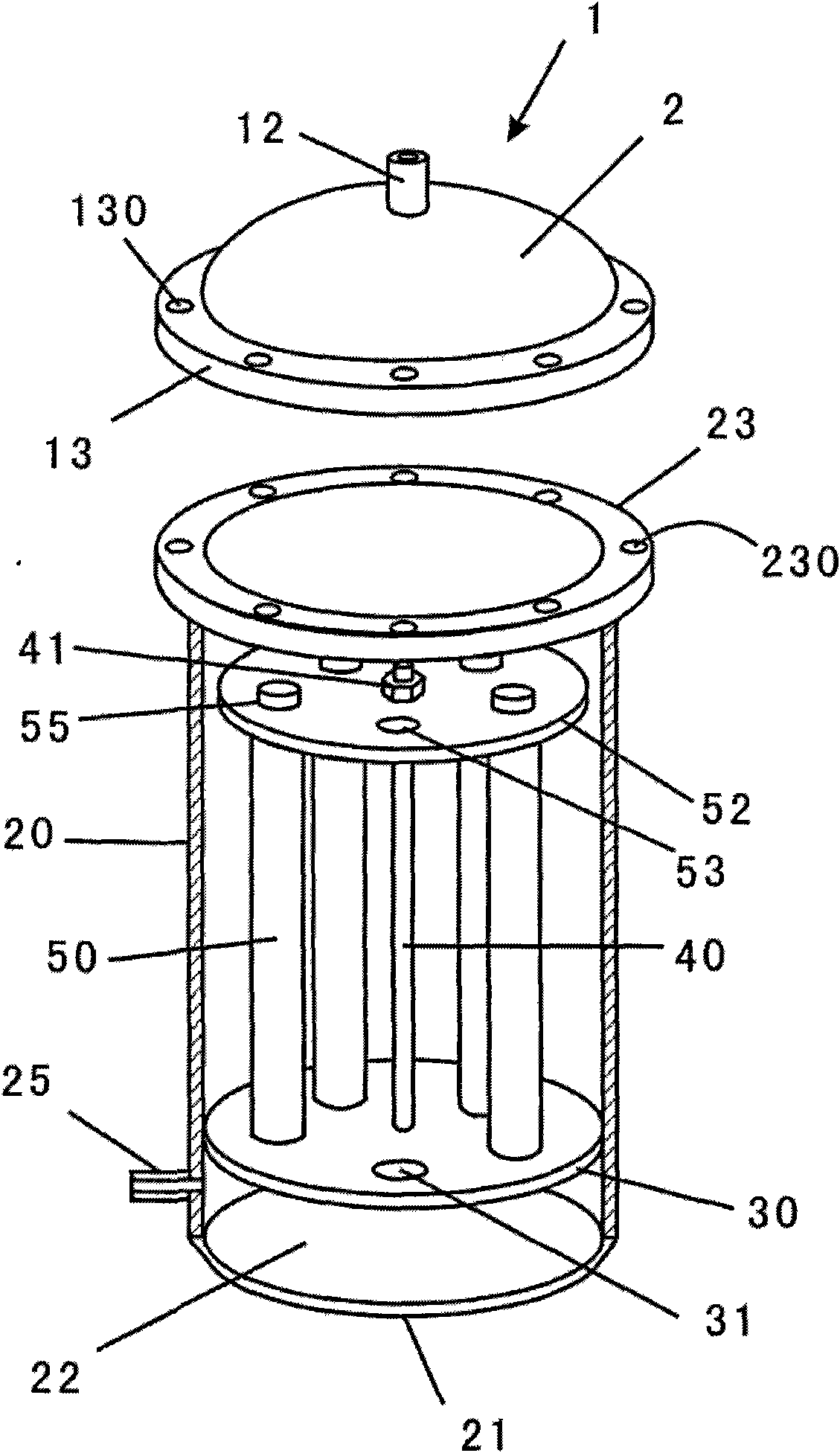

[0068] According to the above method, a device for supporting and fixing a precision filter element with an upper head is designed and manufactured, and the device includes:

[0069] An upper head 10, the upper head 10 has a head butt jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com