Transitional joint of pipe body

A technology of transition joints and pipe bodies, which is applied in the direction of pipes/pipe joints/pipe fittings, passing elements, sealing surface connections, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

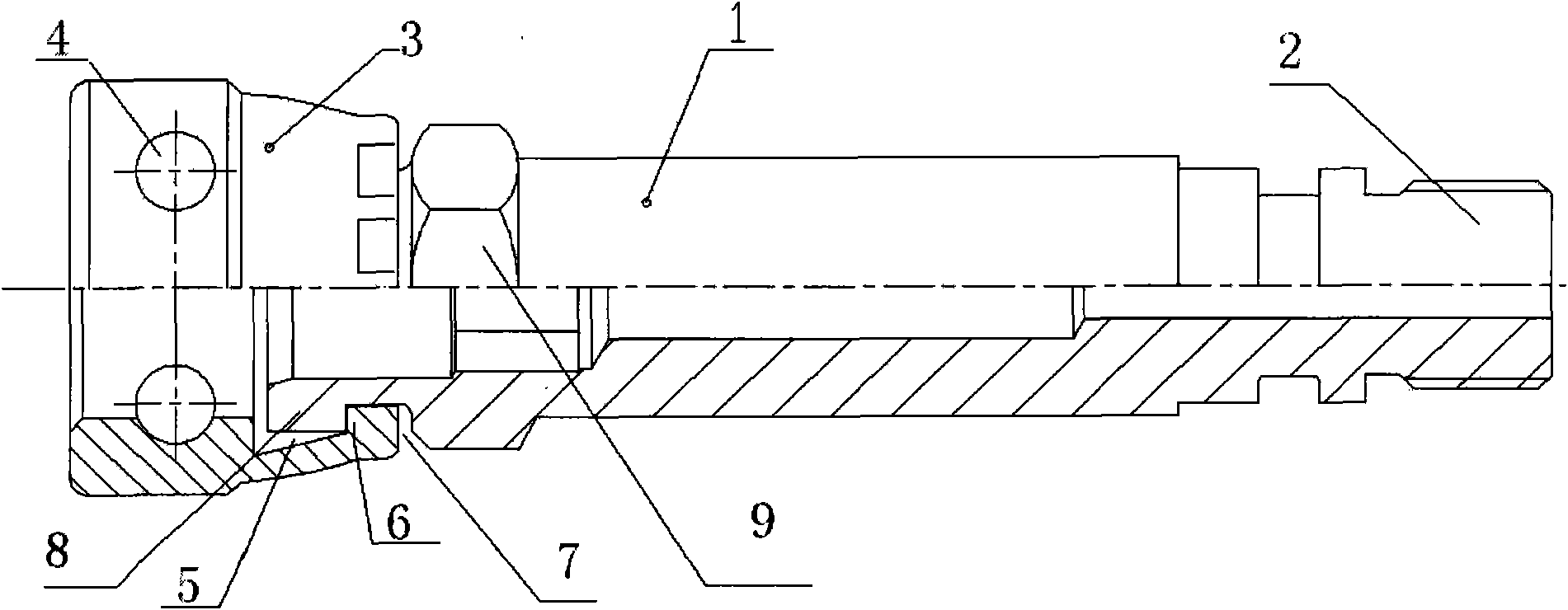

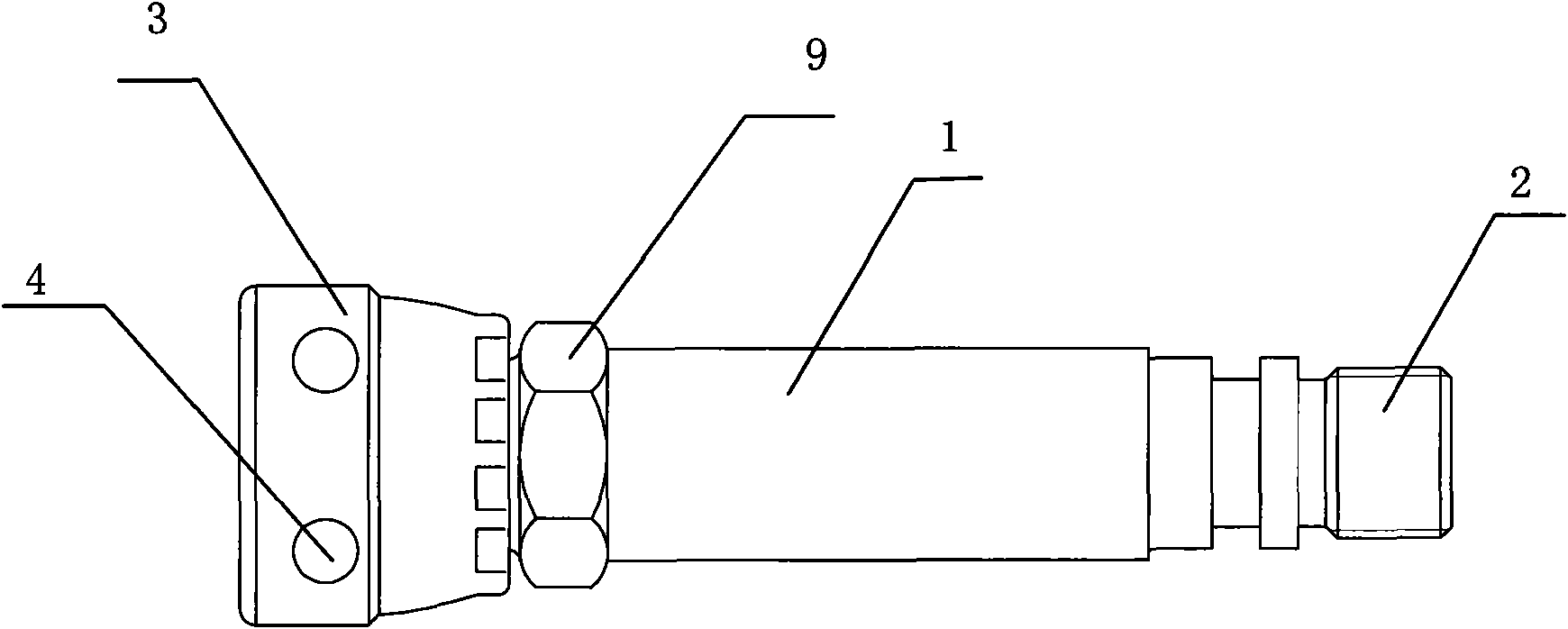

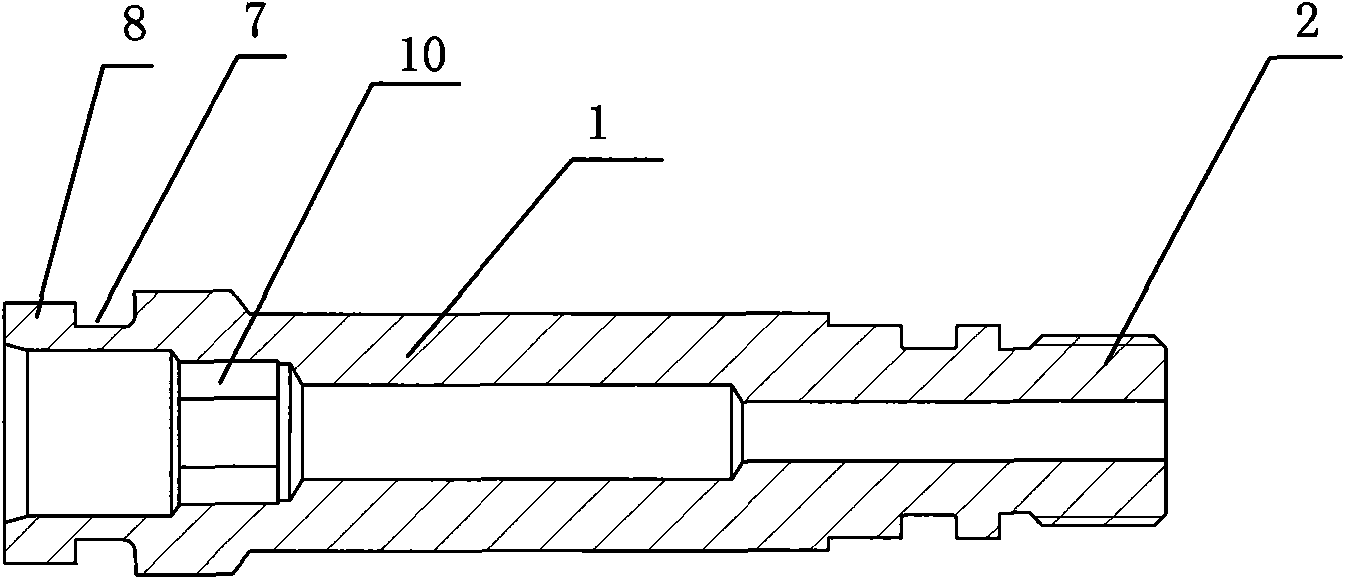

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] A transition joint for a pipe body, comprising a base body 1, one end of the base body 1 is fixedly provided with a joint 2 with an external thread, it also includes a ferrule 3, a U-shaped cartoon hole 4 is arranged on the ferrule 3, and the ferrule 3 includes a second A card slot 5 and a first snap ring 6, the other end of the substrate 1 is provided with a second card slot 7 and a second snap ring 8, the first card slot 5 cooperates with the second snap ring 8, the second card slot 7 cooperates with the first Snap ring 6 cooperates. The joint 2 is integrated with the base body 1 . The base body 1 is provided with an inner hexagonal hole 10 . An outer hexagonal nut 9 is fixed outside the base body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com