Tool clamp facilitating production of belt pulley

A tooling fixture and pulley technology, which is used in manufacturing tools, grinding workpiece supports, grinding drive devices, etc., can solve the problems of troublesome side grinding and easy slippage of the pulley.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

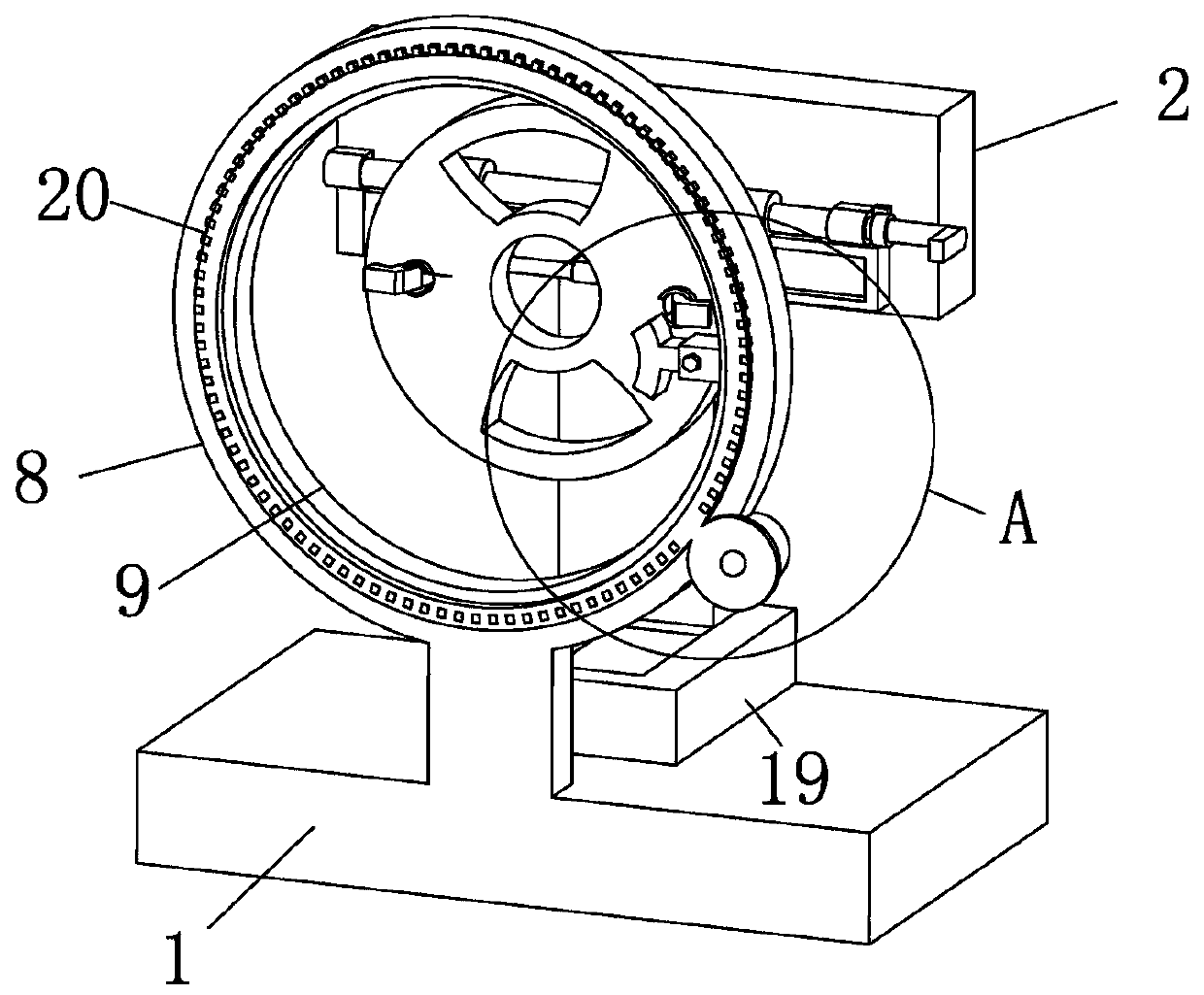

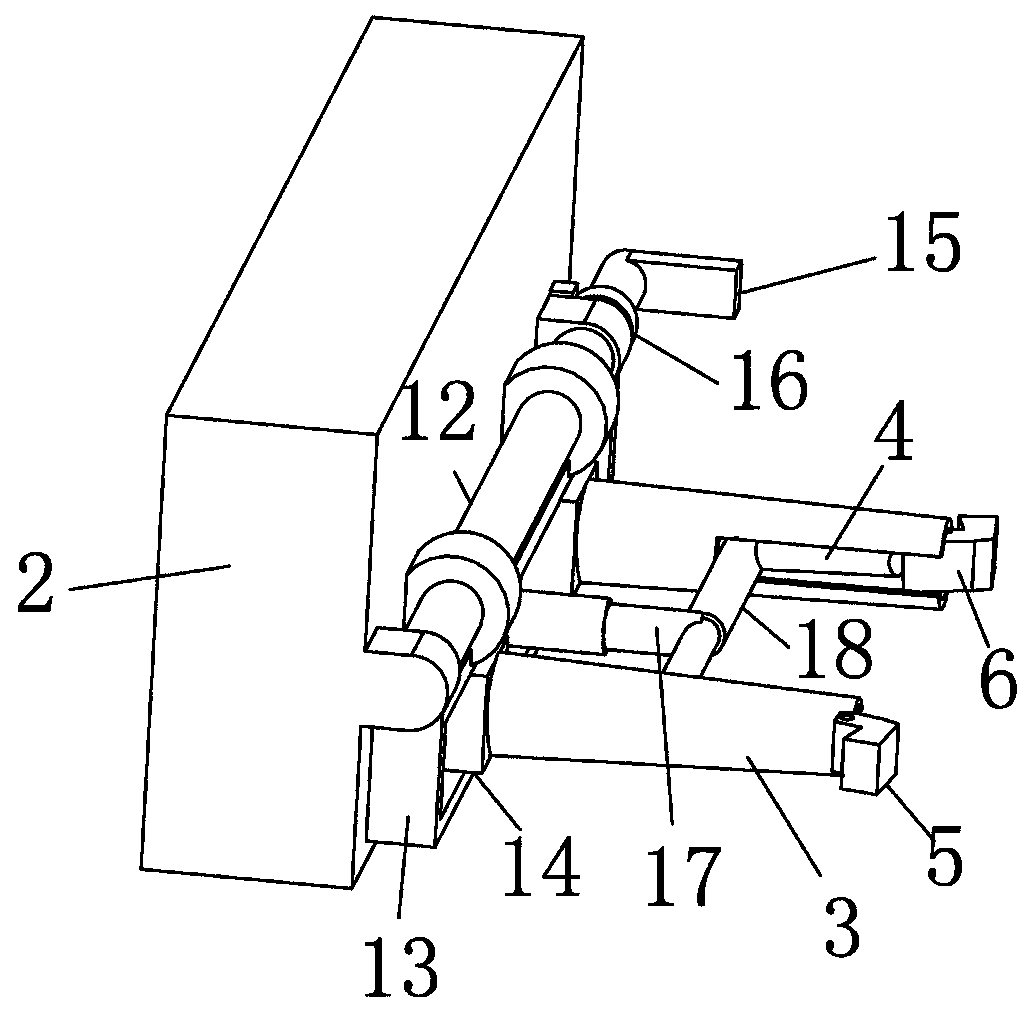

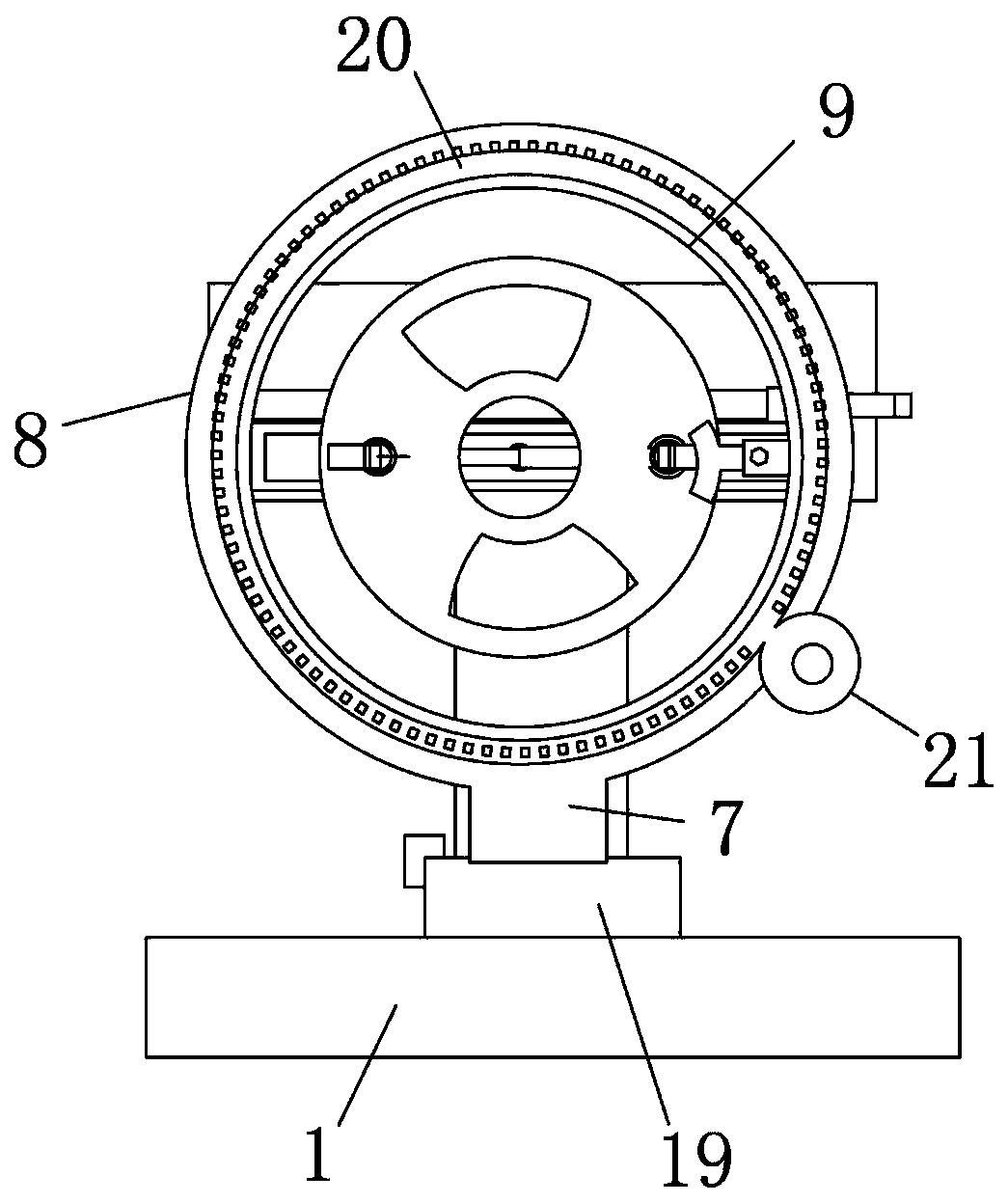

[0022] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0023] Depend on Figure 1-4 Given, the present invention is a tooling fixture convenient for belt pulley production, including a fixed seat 1, on which a clamping installation block 2 is slidably installed, and two clamping columns 3 are slidably installed on the front of the clamping installation block 2, clamping The head of the clamping column 3 is a circular platform structure, and the clamping column 3 is a hollow tubular structure. The head of the clamping column 3 is a circular platform structure. The two perforations of the pulley are set behind the clamping column 3. Belt pulley can be made to slide towards the head of clamping post 3 when sliding outside.

[0024] The inside of the clamping column 3 is slidingly installed with a push rod 4, and the head of the clamping column 3 is hingedly equipped with a clamping block 5, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com