Universal mould clamp

A mold clamp and template technology, which is applied in the field of general mold clamps, can solve problems such as poor adaptability, potential safety hazards, and mold clamps that cannot be used universally, and achieve the effects of convenient operation, good adaptability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings, and described in detail, so that the functions and characteristics of the present invention can be better understood.

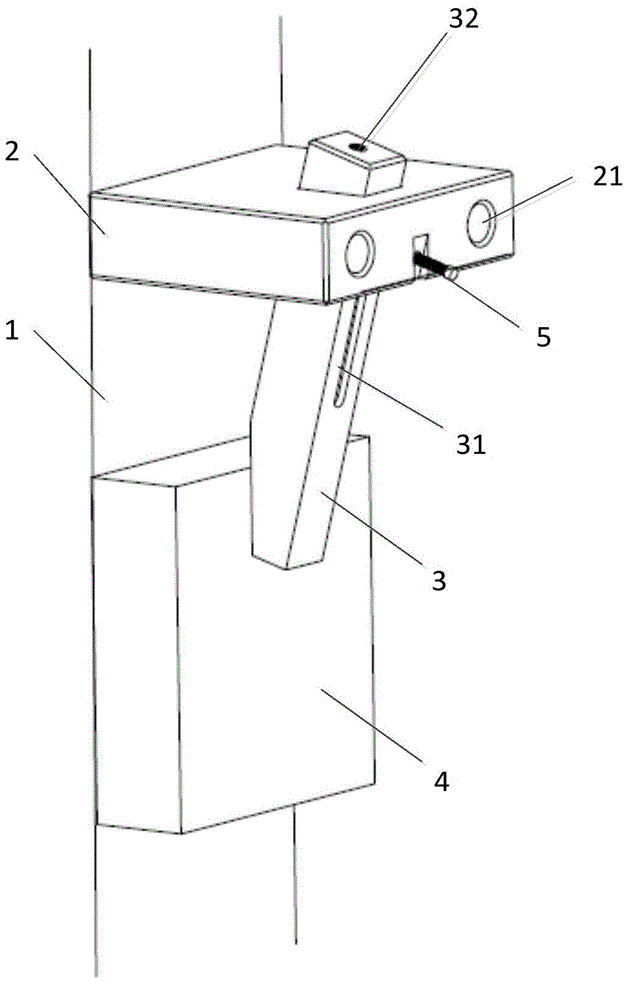

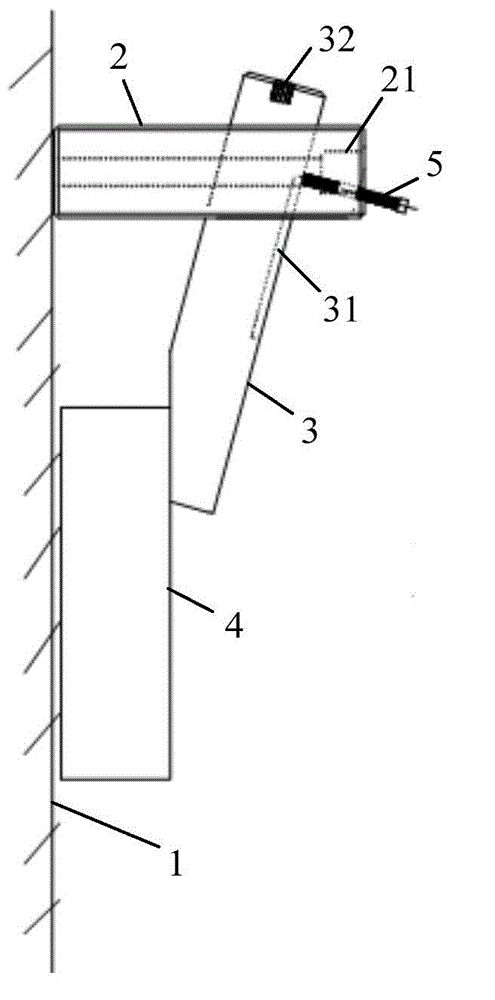

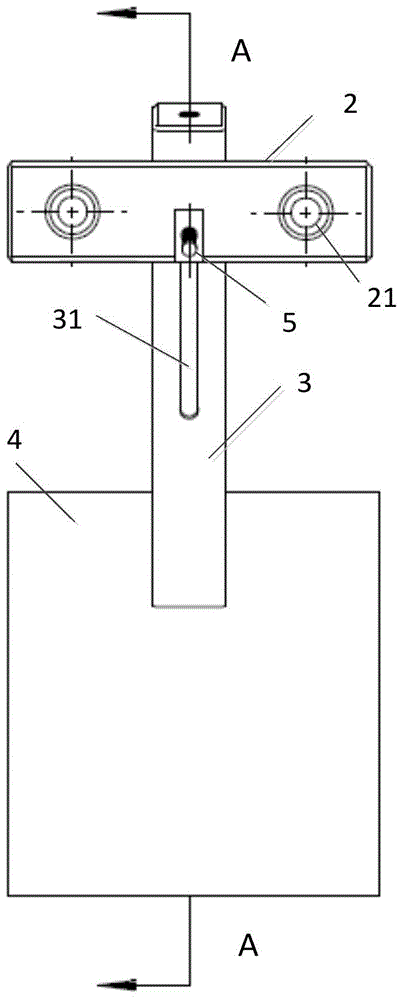

[0016] Such as Figure 1-4 As shown, the universal mold clamp of the present invention includes a fixed plate 2 vertically fixedly installed on the template 1 of the injection molding machine, and a locking column 3 extending obliquely through the center of the fixed plate 2, wherein the lock The tight column 3 is provided with a positioning groove 31 in the axial direction on the side facing away from the template 1 of the injection molding machine, and a first fastener (shown as a locking bolt 5 in the figure) extends through the fixing plate 2 and enters the positioning groove 31 to connect the locking column 3 and the fixed plate 2 together. In addition, the locking column 3 also has a pressing surface that cooperates with the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com