Plate heat exchanger

一种板式换热器、换热板片的技术,应用在间接换热器、换热器类型、热交换设备等方向,能够解决不具有等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

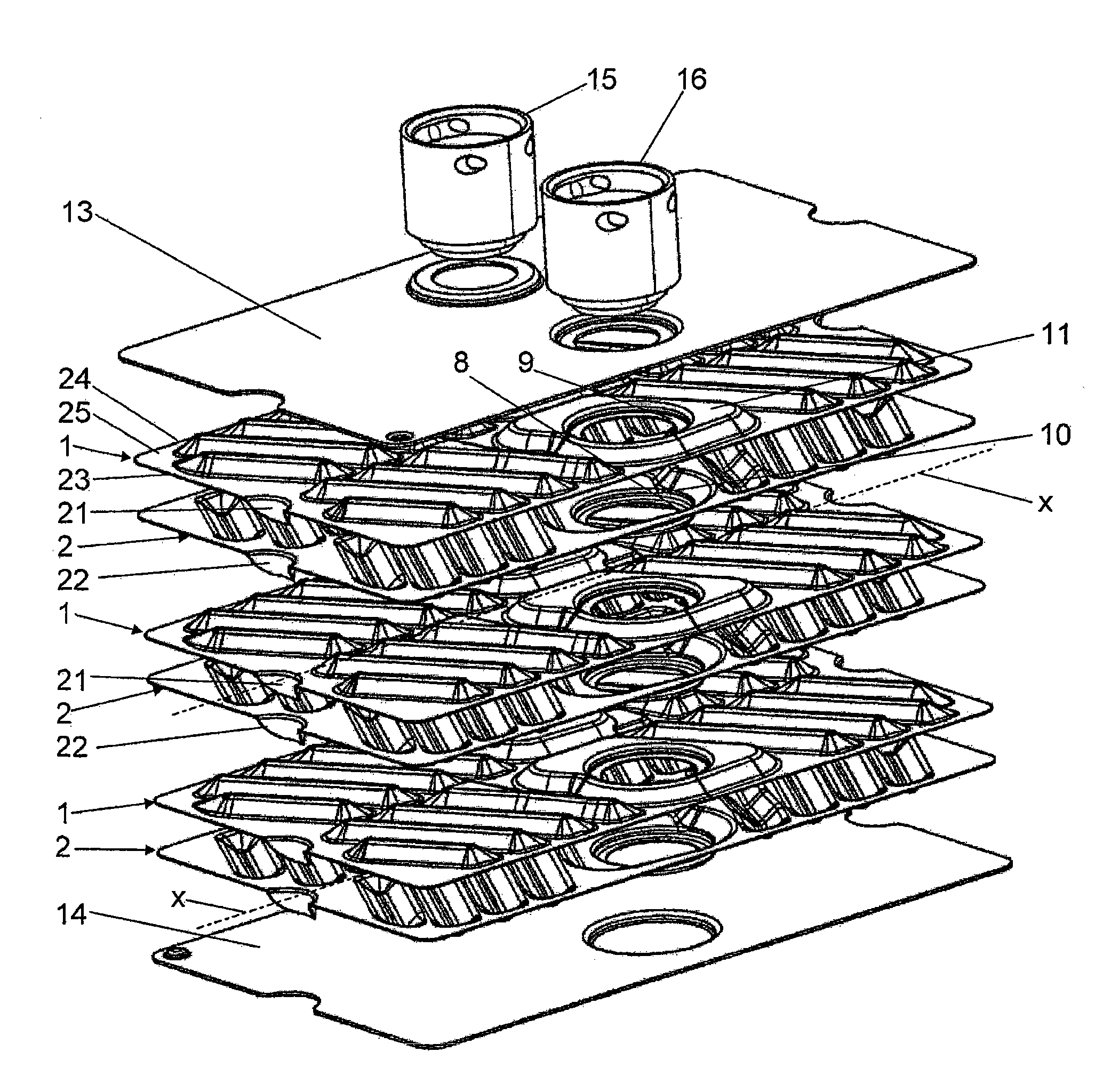

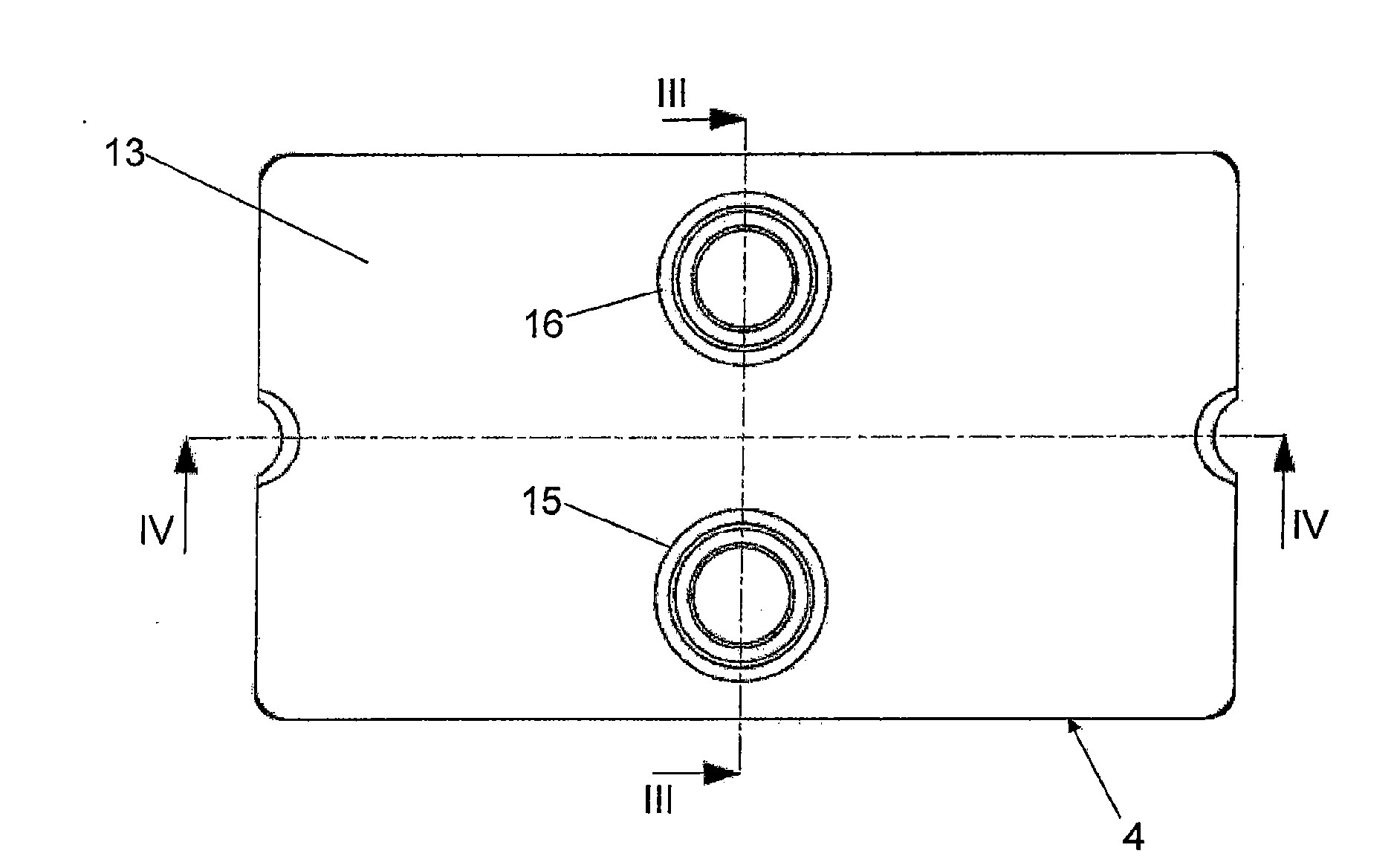

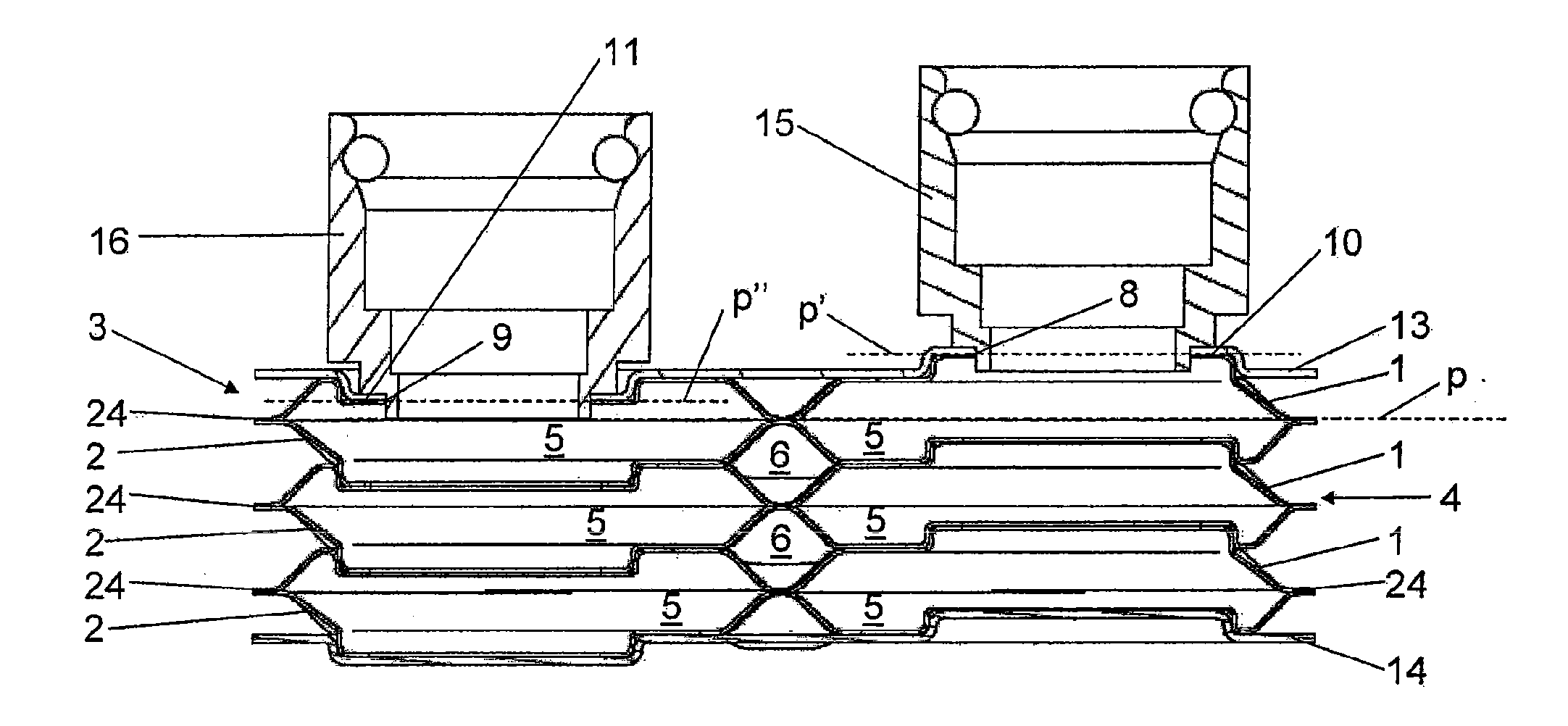

[0022] refer to Figure 1 to Figure 5 , discloses an embodiment of a plate heat exchanger. The plate heat exchanger includes a plurality of heat exchange plates 1 , 2 . The heat exchange plates 1 and 2 are composed of a first heat exchange plate 1 and a second heat exchange plate 2 . In the plate heat exchanger, all the heat exchange plates 1, 2 have heat exchange function. Each heat exchange plate 1, 2 extends parallel to the main extension plane p, see image 3 . The extension plane p can be seen as extending through and parallel to the base plane of the respective heat exchange plates 1, 2 from which the planar heat exchange plates 1, 2 have been molded in a manner known per se , thereby obtaining an embossed pattern comprising a corrugated heat exchange pattern and a port region pattern.

[0023] The heat exchange plates 1 , 2 are arranged next to each other so that they form a plate assembly 3 with sides 4 which extend around the plate assembly 3 . The heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com