heat sink

一种散热器、散热片的技术,应用在电固体器件、半导体器件、冷却/通风/加热改造等方向,能够解决安全隐患、划伤其他元件等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

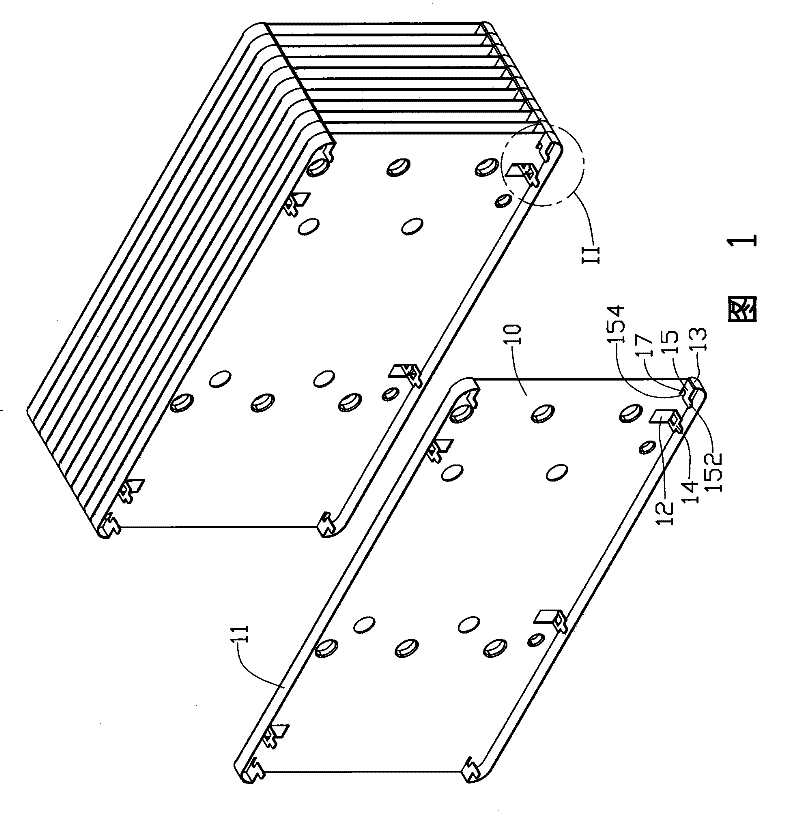

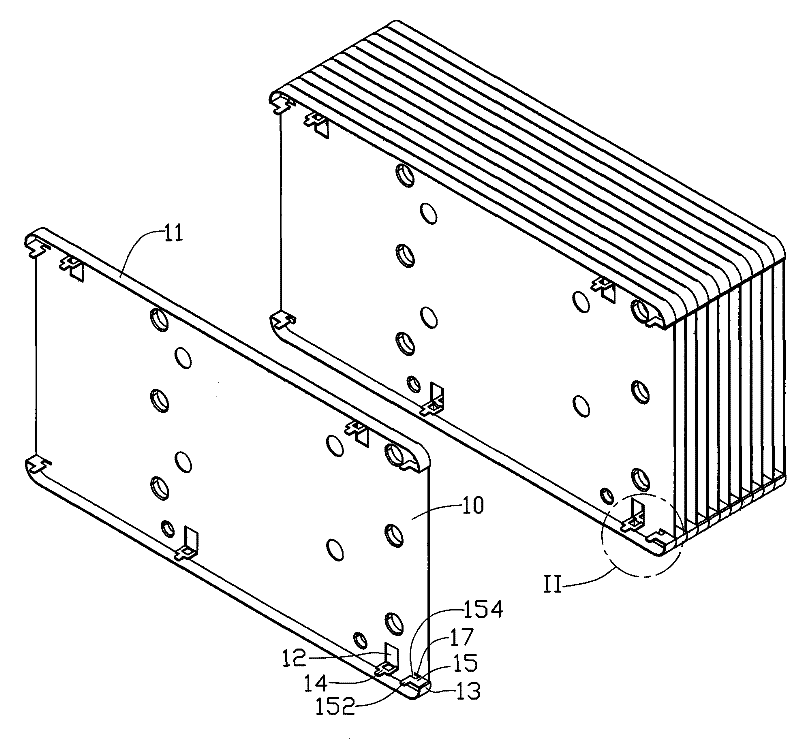

[0012] The radiator of the present invention is used to dissipate heat from heating electronic components such as a central processing unit (not shown in the figure).

[0013] like figure 1 and 2 As shown, the radiator of the present invention can be installed directly on the heating electronic components, or can be installed on a base (not shown) in contact with the heating electronic components.

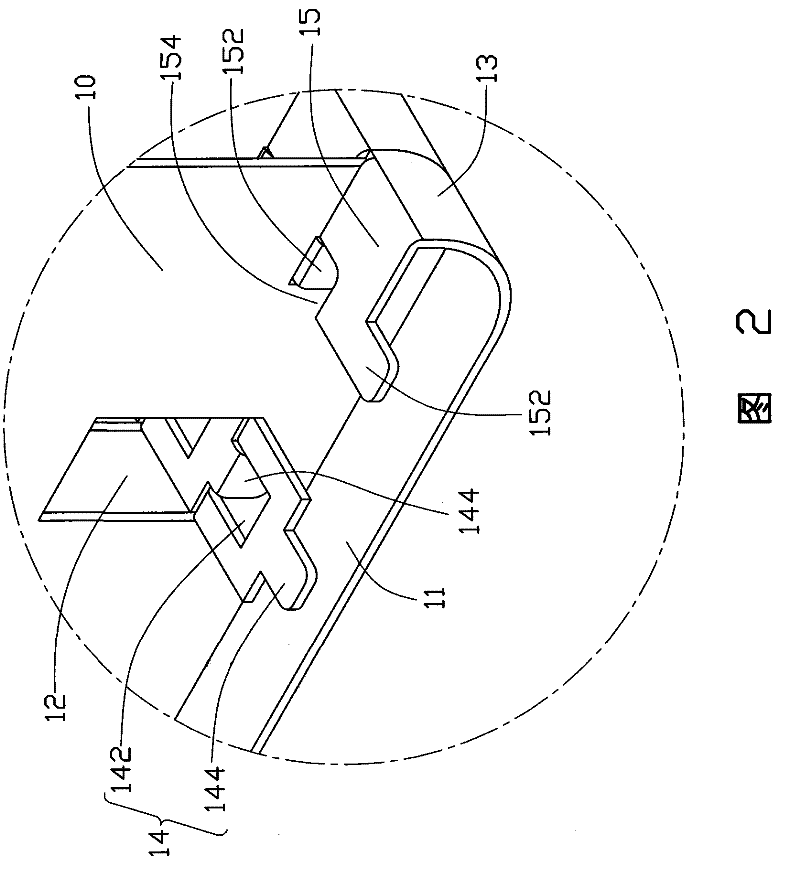

[0014] The above-mentioned heat sink includes a plurality of cooling fins 10 that are interlocked together. Each cooling fin 10 includes a large rectangular body and a flange 11 extending vertically to the same side from the upper and lower edges of the body. All the cooling fins 10 When combined together, the folded edges 11 of the upper and lower ends respectively form two planes that can contact the surface of the base or the top surface of the heating electronic component. The heat sink 10 is respectively provided with two first fastening structures spaced apart from each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com