Magnetostrictor actuator

A magnetostrictive and actuator technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the complex structure of the actuator and the increase in overall size and other issues, to achieve the effect of good linear drive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

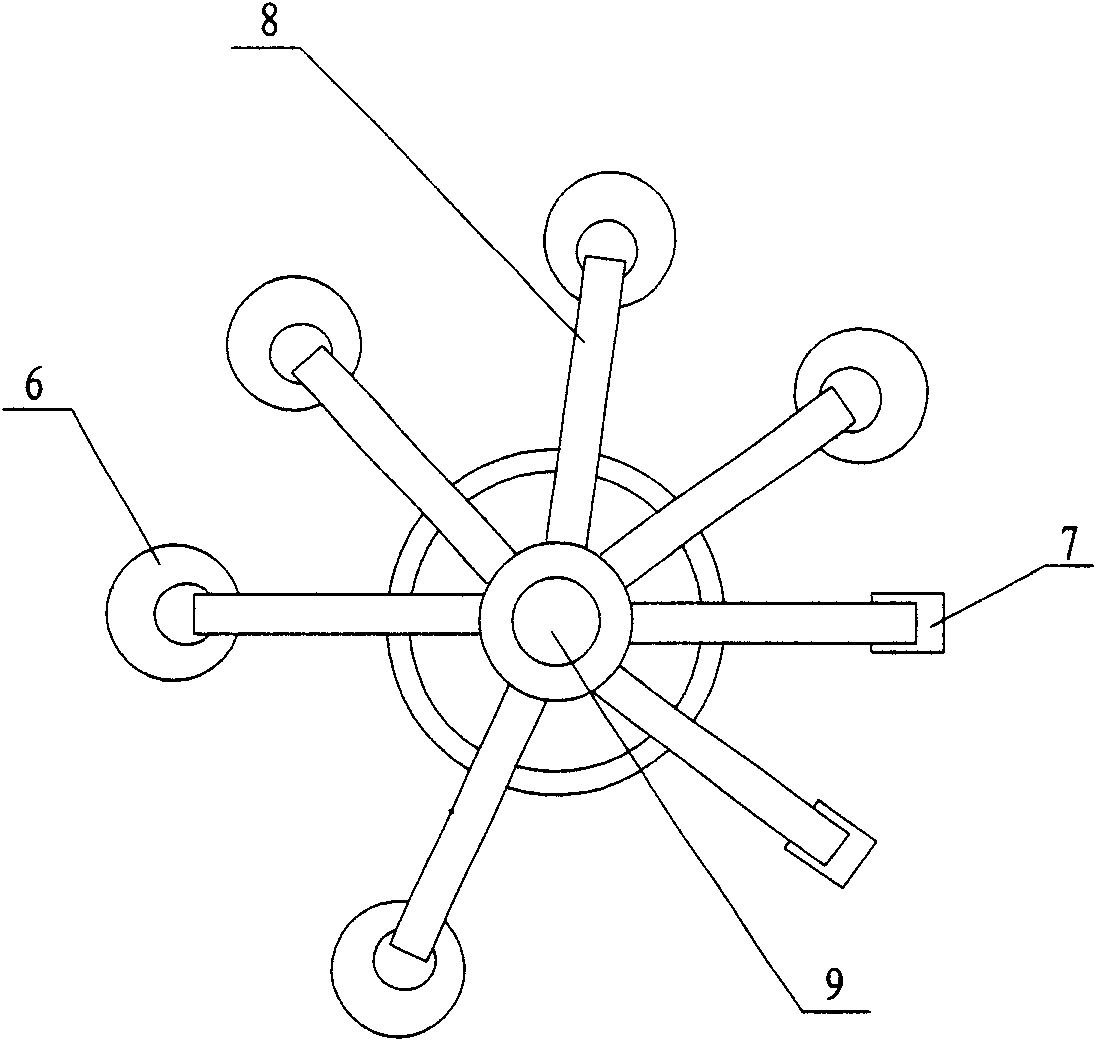

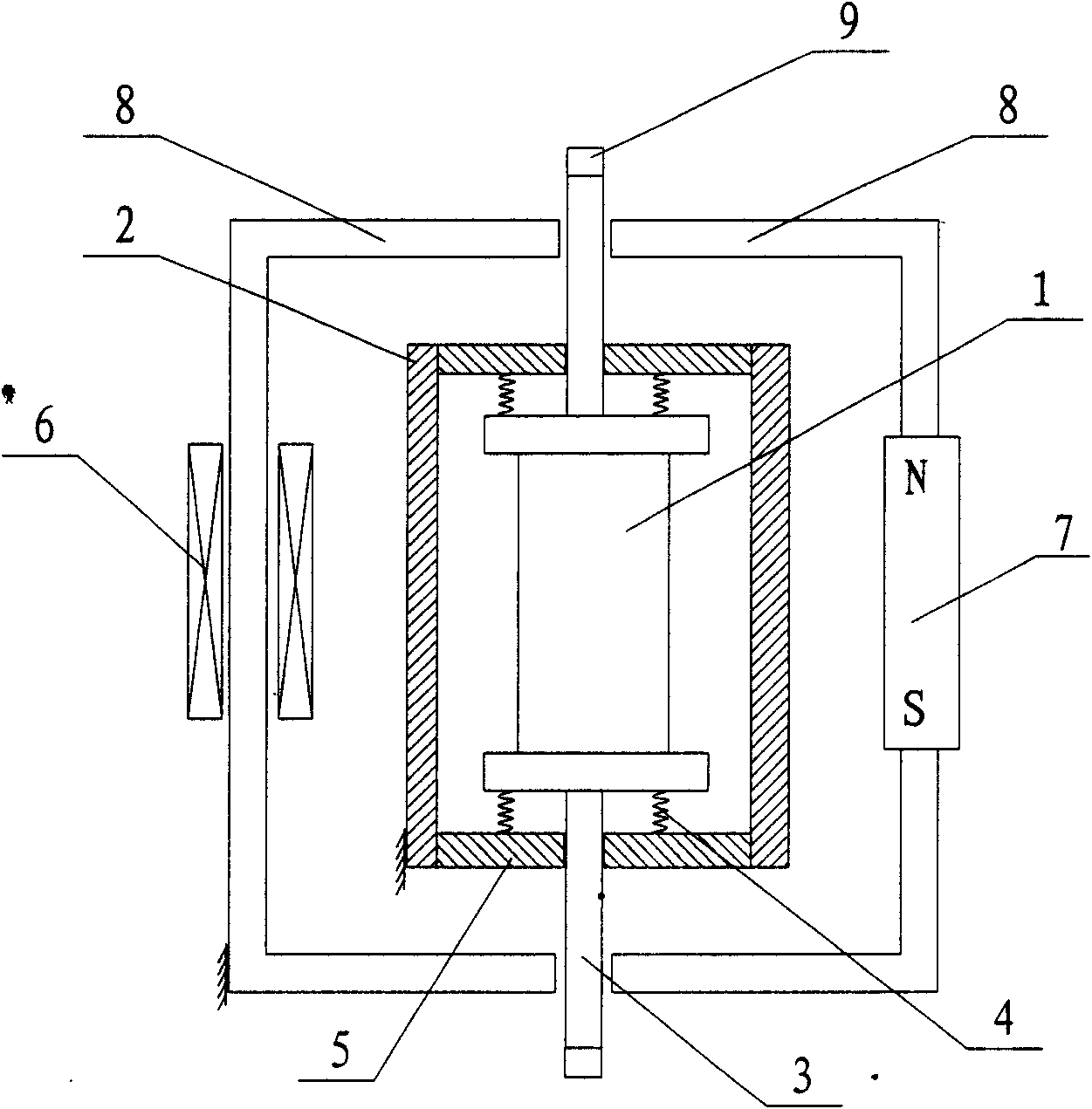

[0027] Such as figure 1 , 2 , 3, the mechanism of the present invention includes a rigid non-magnetic support 2 and a magnetostrictive body 1 arranged in the rigid non-magnetic support 2, and the opposite sides of the rigid non-magnetic support 2 are provided with through openings. A rigid magnetically conductive rod 3 that can move freely relative to the through opening is provided, and the rigid magnetically conductive rod 3 is fixedly connected to the magnetostrictive body 1; One side is open, and the other sides are closed; the periphery of the rigid magnetic conductive support 8 is wound with an electromagnetic coil 6; the magnetostrictive body 1, the rigid magnetic conductive rod 3 and the rigid magnetic conductive support 8 form an electromagnetic flux circuit 10, Set five. The rigid magnetically conductive rod 3 can move freely relative to the opening side of the rigid magnetically permeable support; the rigid non-magnetically permeable support 2 and the rigid magnet...

Embodiment 2

[0035] Such as Figure 4 As shown, the mechanism of the present invention includes a rigid non-magnetic support 2 and a magnetostrictive body 1 arranged in the rigid non-magnetic support 2. One side of the rigid non-magnetic support 2 is provided with a through opening, and the through opening is arranged relative to the through opening. A rigid magnetically conductive rod 3 that can move freely, and the rigid magnetically conductive rod 3 is fixedly connected to the magnetostrictive body 1; a rigid magnetically conductive support 8 is provided on the outside of the rigid non-magnetically conductive support 2, and one side of the rigid magnetically conductive support 8 is open , the remaining sides are closed; the rigid non-magnetically conductive support 2 is provided with an opening on the side opposite to the through opening, and the rigid magnetically conductive support 8 is directly connected to the magnetostrictive body 1 after penetrating through the opening. An electro...

Embodiment 3

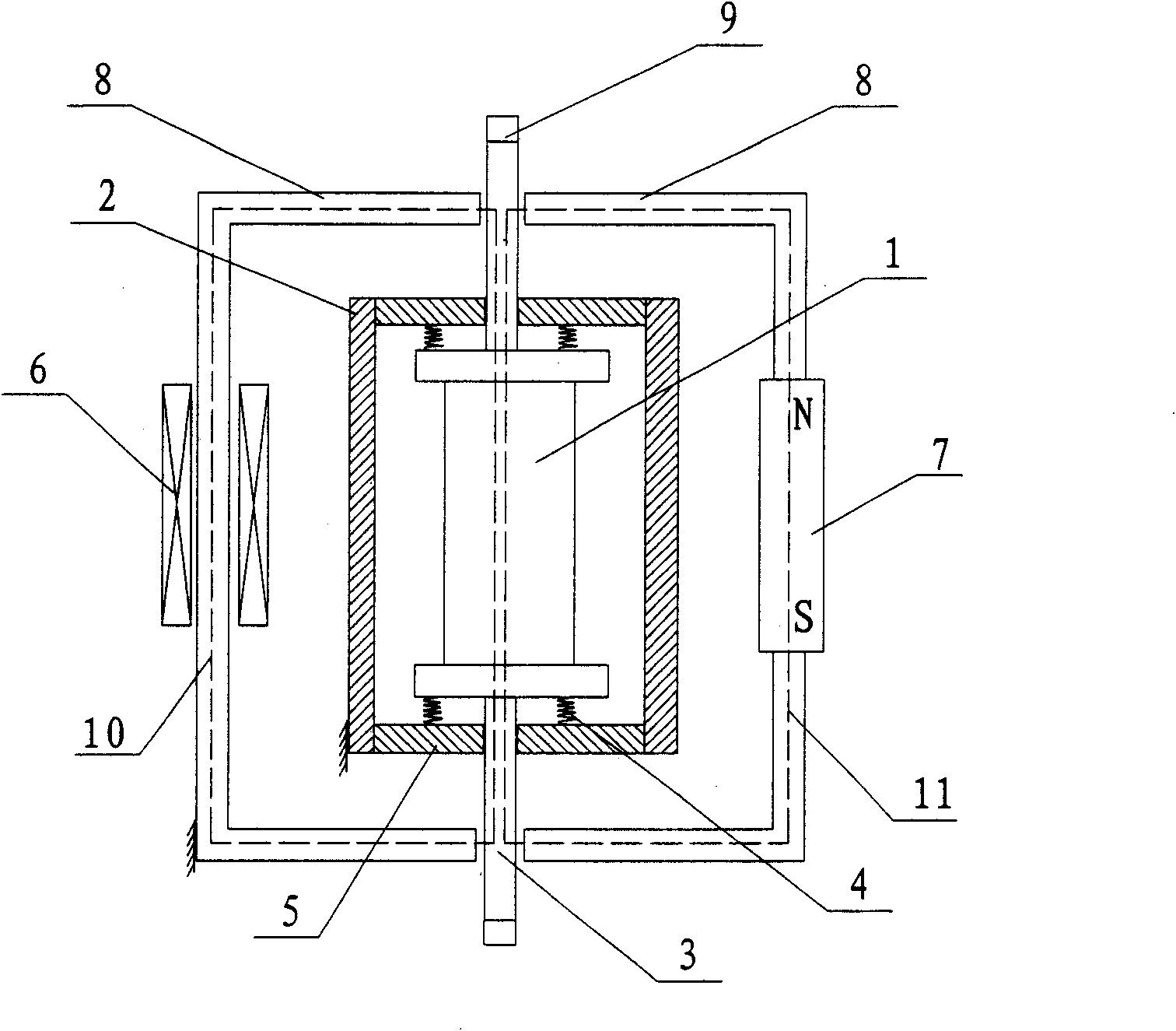

[0038] Such as Figure 5 As shown, the mechanism of the present invention includes a rigid non-magnetic support 2 and a magnetostrictive body 1 arranged in the rigid non-magnetic support 2. The opposite sides of the rigid non-magnetic support 2 are provided with through openings. The rigid magnetically conductive rod 3 that can move freely at the through-hole, the rigid magnetically conductive rod 3 is fixedly connected with the magnetostrictive body 1; One side is open, and the other sides are closed; the periphery of the rigid magnetically conductive support 8 is wound with an electromagnetic coil 6; The magnetostrictive body 1 is excited. The rigid magnetically conductive rod 3 can move freely relative to the opening side of the rigid magnetically permeable support; the rigid non-magnetically permeable support 2 and the rigid magnetically permeable support 8 are both fixedly arranged.

[0039] A spring 4 is arranged on both sides of the rigid magnetic rod 3 in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com