Cutting tool

A cutting tool and tool technology, applied in manufacturing tools, stone processing tools, metal sawing equipment, etc., can solve problems such as tool jamming, cutting edge breakage, downtime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

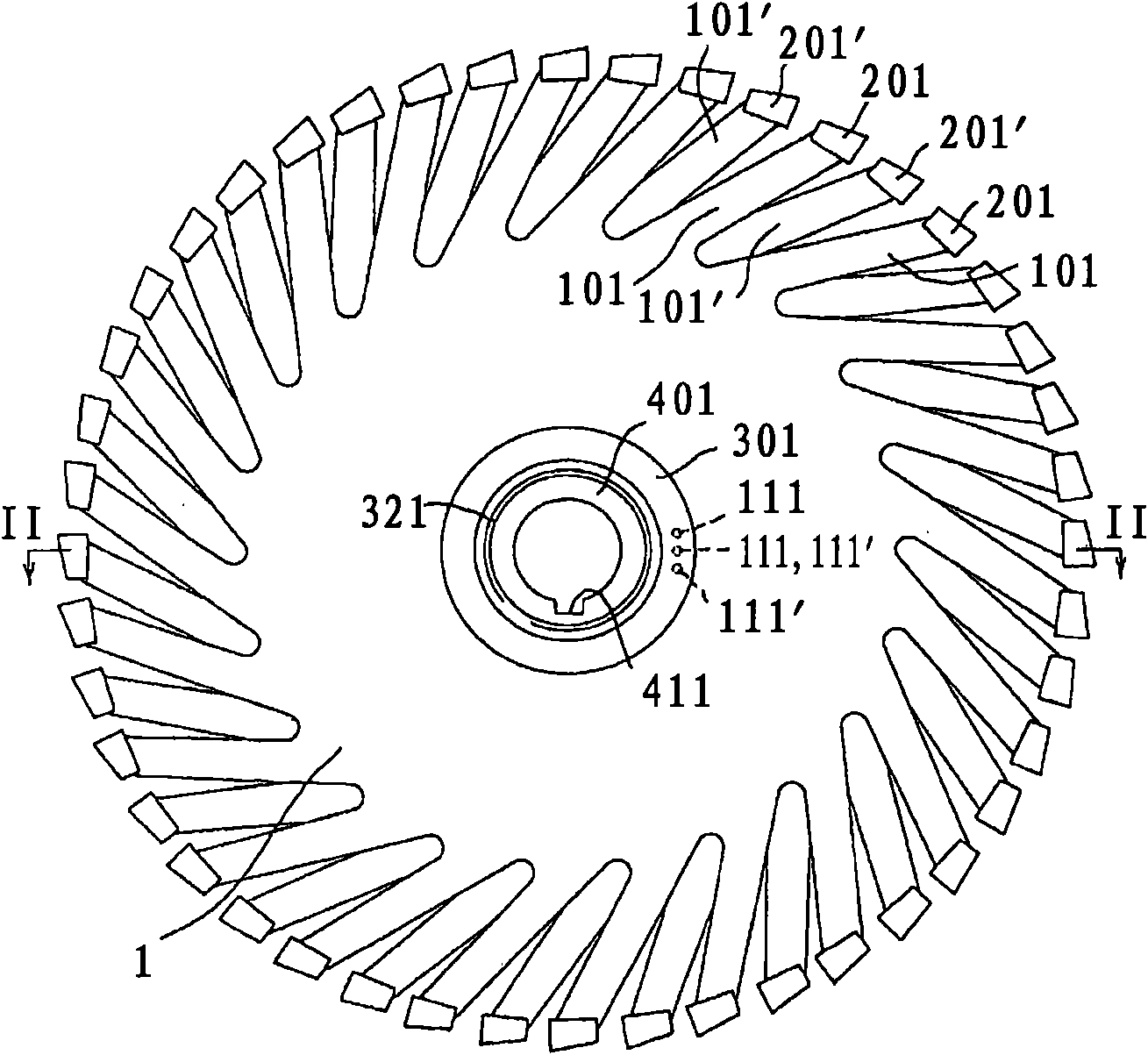

[0011] figure 1 A cutting tool according to the invention is shown; reference numeral 1 designates a structural element of said tool, said structural element comprising two discs 1 and 1' (cf. figure 2 ), a plurality of arms 101, 101' for supporting the cutting edges 201, 201' protrude from said two discs; in this case, the two discs 1, 1' are fixed on the sleeve 401 by means of screws The rings 301 are connected together. Inside the sleeve 401 there is also a radial cavity 411 which allows it to engage with a power take-off (not shown) of the operating device. Holes 111, 111' shown by dotted lines are formed in discs 1 and 1', respectively, from figure 2 As shown, it can be seen that the holes place the two disks opposite each other.

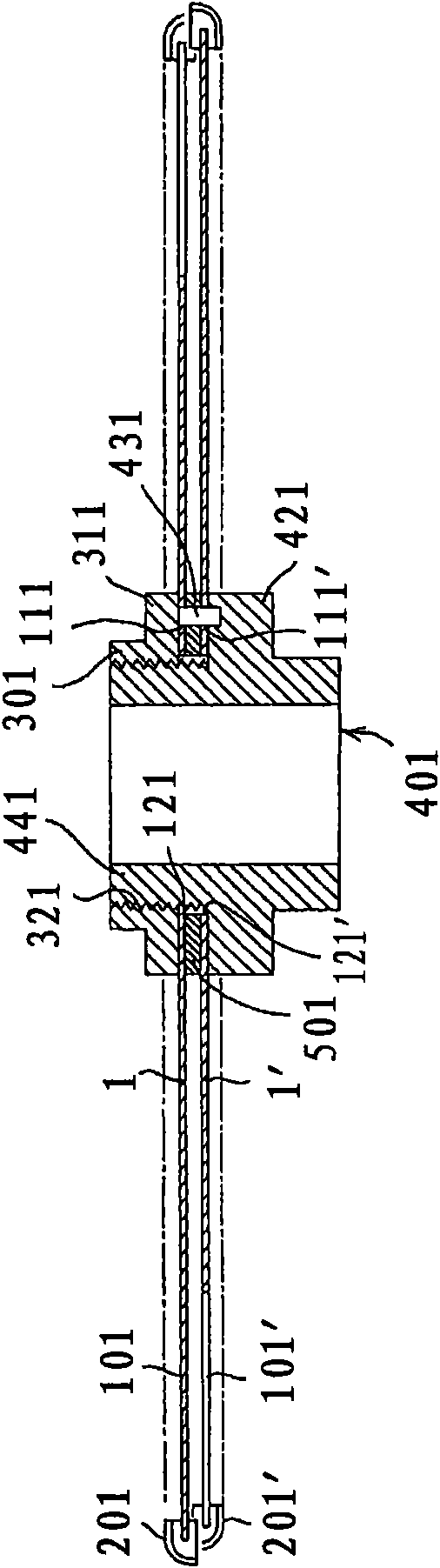

[0012] figure 2 shown figure 1 Tool cut along line II-II. It can be noted that, like the axial hole 121 of the disk 1, the disk 1' is positioned on the threaded sleeve 441 of the sleeve 401 by means of its axial hole 121'; the spacer r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap