Method for detecting corrosiveness of electronic-equipment application environment, and corresponding electronic equipment

A technology of electronic equipment and detection methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as inability to take countermeasures in time, and achieve simple structure, low cost, and promising application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

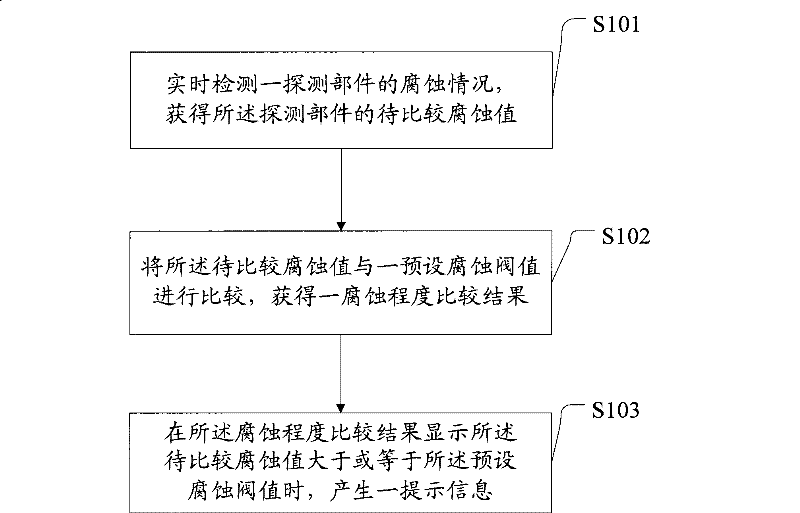

Method used

Image

Examples

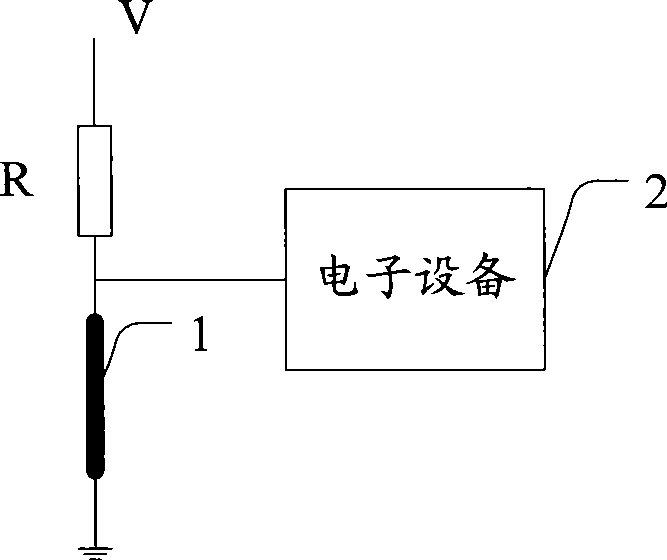

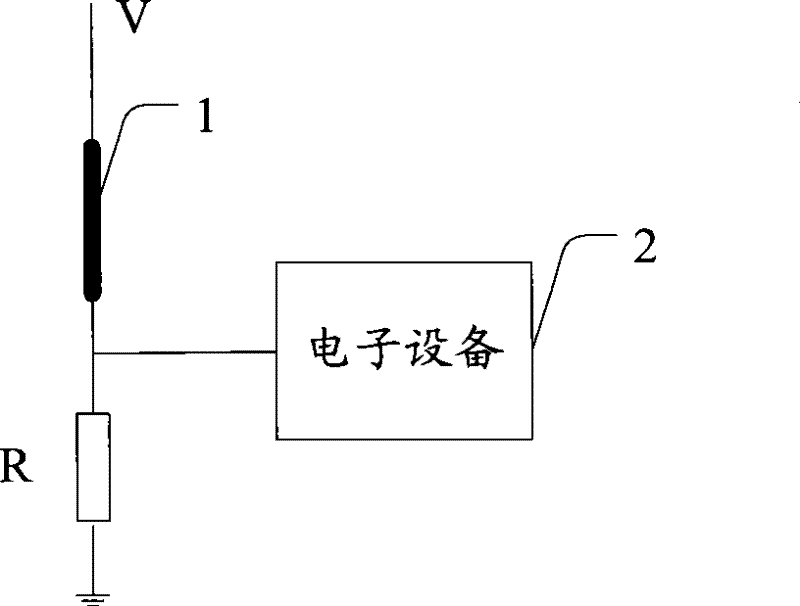

Embodiment Construction

[0039] For ease of description, the terms used in the embodiments of the present invention are first explained:

[0040] The Board Management Controller (BMC) is a dedicated service processor that uses sensors to monitor the status of a computer, network server, or other hardware-driven device, and manages it through an independent connection line and system staff to communicate.

[0041] The BMC is part of the Intelligent Platform Management Interface (IPMI) and is usually included on the motherboard or the main circuit board of the device being monitored.

[0042]The BMC's sensors can be used to measure internal physical variables such as temperature, humidity, supply voltage, fan speed, communication parameters and operating system (OS) functions. If any of these variables are out of bounds, the BMC notifies the administrator. Administrators can then use the remote control to take corrective action by power cycling the monitored equipment or restarting it if necessary. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com