Magnetic sensor

A magnetic sensor and magnetic detection technology, which is applied in the direction of measuring the geometric arrangement of magnetic sensing elements, instruments, and using electromagnetic devices for magnetic field measurement, etc., can solve the problems of different temperatures, large changes in resistance values, and inability to obtain suppression effects. Achieve high-precision magnetic detection and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]

A magnetic sensor according to a first embodiment of the present invention will be described with reference to the drawings.

[0021]

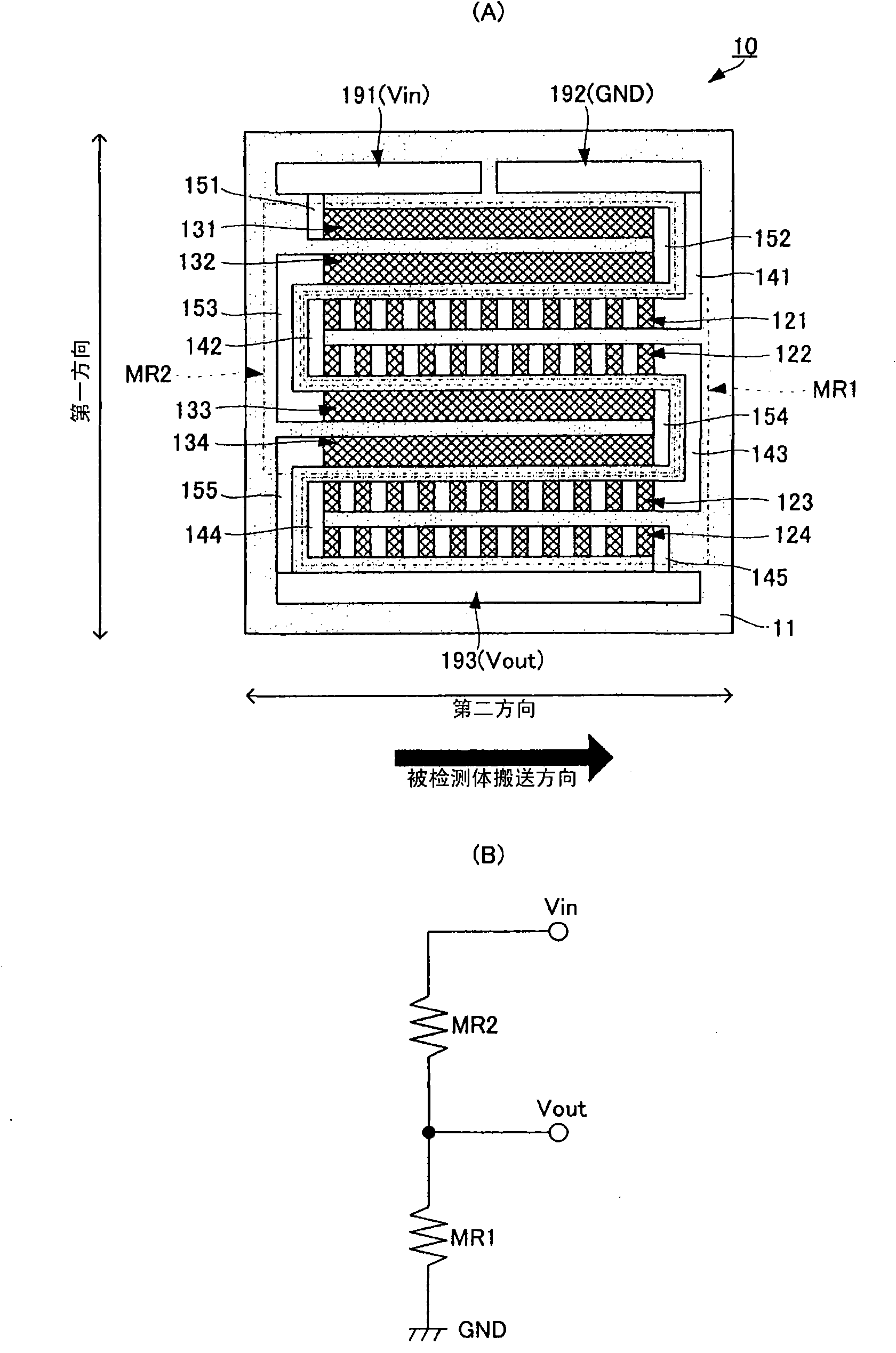

figure 1 (A) is a plan view showing the structure of the magnetic sensor 10 of this embodiment, figure 1 (B) is an equivalent circuit diagram of the magnetic sensor 10 .

[0022]

Such as figure 1 As shown in (A), the magnetic sensor 10 is constituted by forming a magnetically sensitive part on a substrate 11, connecting wire electrodes connected to the magnetically sensitive part, and external connection electrodes used for voltage input / output or ground connection. figure 1 (B) The circuit shown. That is, a circuit is configured in which the magnetoresistive elements MR1 and MR2 are connected in series between the voltage input terminal Vin and the ground terminal GND, and the voltage output terminal Vout is connected to the connection point of the magnetoresistive elements MR1 and MR2. Hereinafter, a specific structure is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap