Testing box for accelerated environment

An environmental test chamber and test chamber technology, applied in the direction of program control and temperature control in instruments, sequence/logic controllers, etc., can solve problems such as limiting the scope of application, accelerating corrosion test, reducing accelerated corrosion, etc., so as to improve corrosion resistance. and aging speed, test data uniformity, and improve the effect of acceleration magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

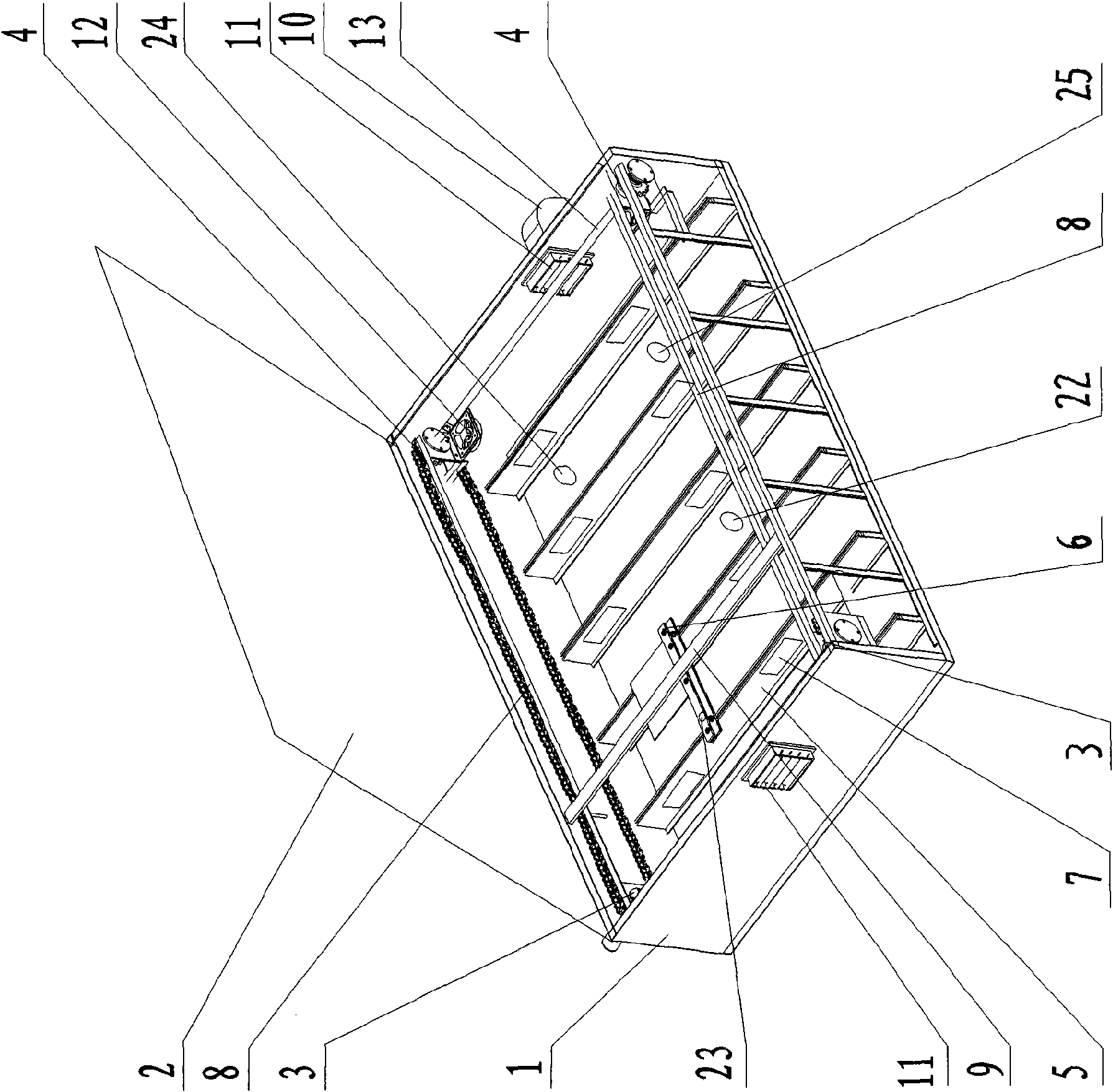

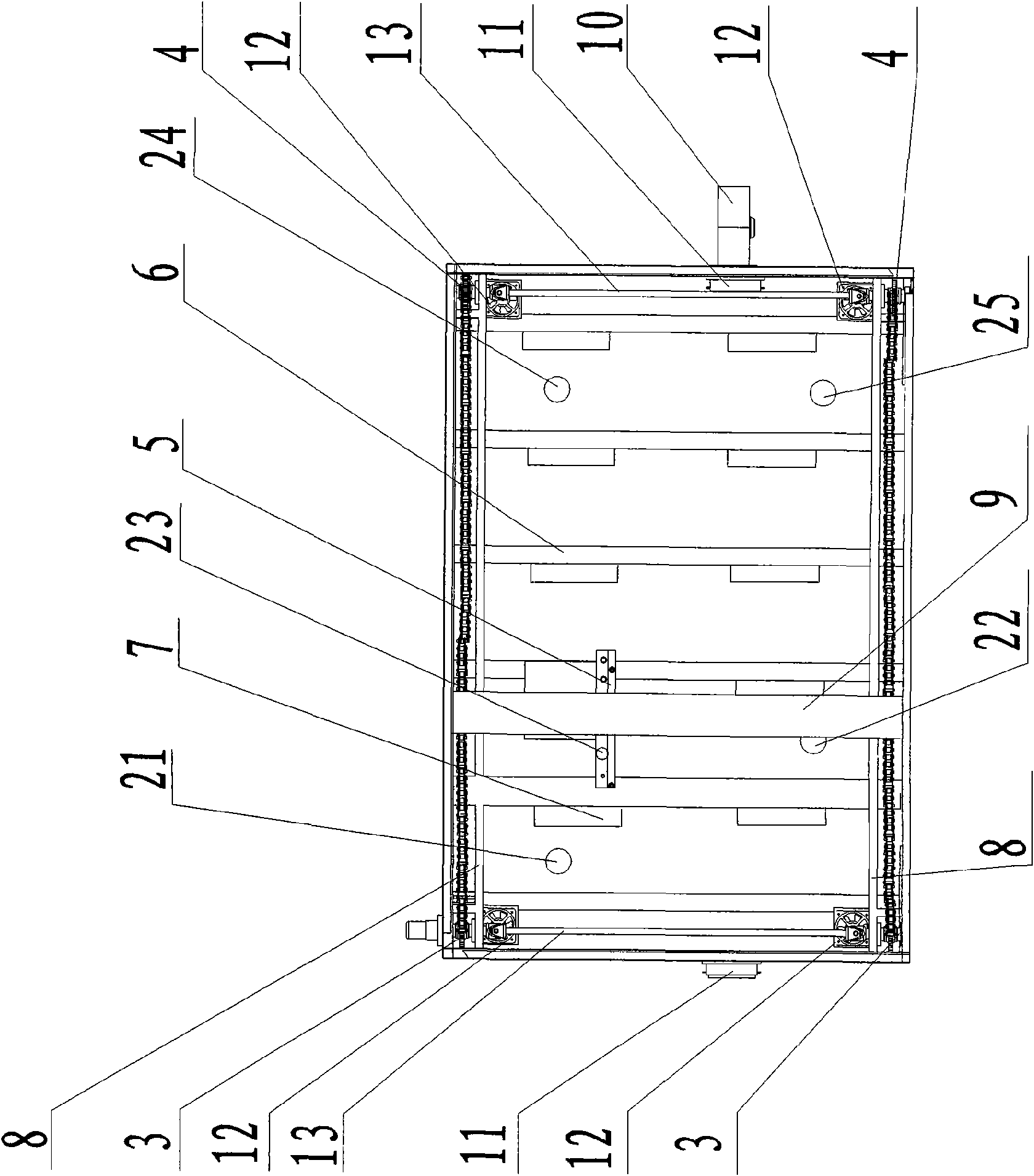

[0030] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0031] An accelerated environment test box comprises a box body 1 and a transparent cover plate 2, and a mobile spraying system is arranged in the box body 1. Mobile misting systems include:

[0032] The spray device is used to spray the samples in the test chamber, including a liquid storage tank, a water pump with a water inlet pipe and a water outlet pipe, and a spray pipe with a nozzle. The water inlet pipe is connected to the liquid storage tank, and the water outlet pipe is connected to the spray pipe ;

[0033] The moving device is used for the spray tube to move in the box body 1, including two driving gears 3 oppositely arranged at one end of the test box and connected through the cross coupling 13, and oppositely arranged at the other end and connected through the cross coupling 13 Two driven gears 4, the driving gear 3 and the driven gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com