Rotating knife of food cooking machine

A technology of rotating knives and cooking utensils, which is applied in grain processing, household utensils, kitchen utensils, etc. It can solve the problems of poor cutting effect, high motor loss rate, and large power consumption, and achieves small mechanical wear and low motor loss rate. , the effect of small power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

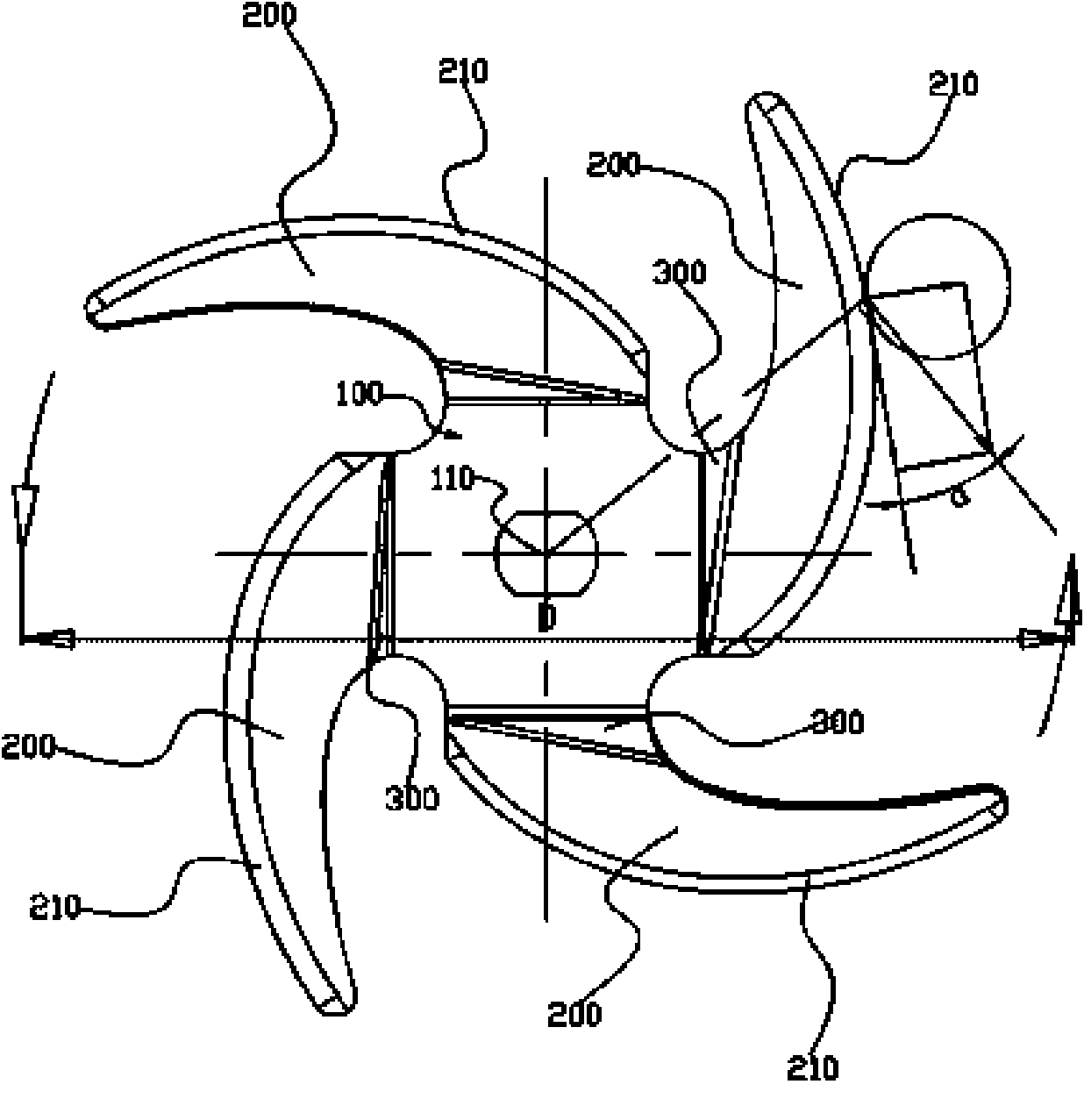

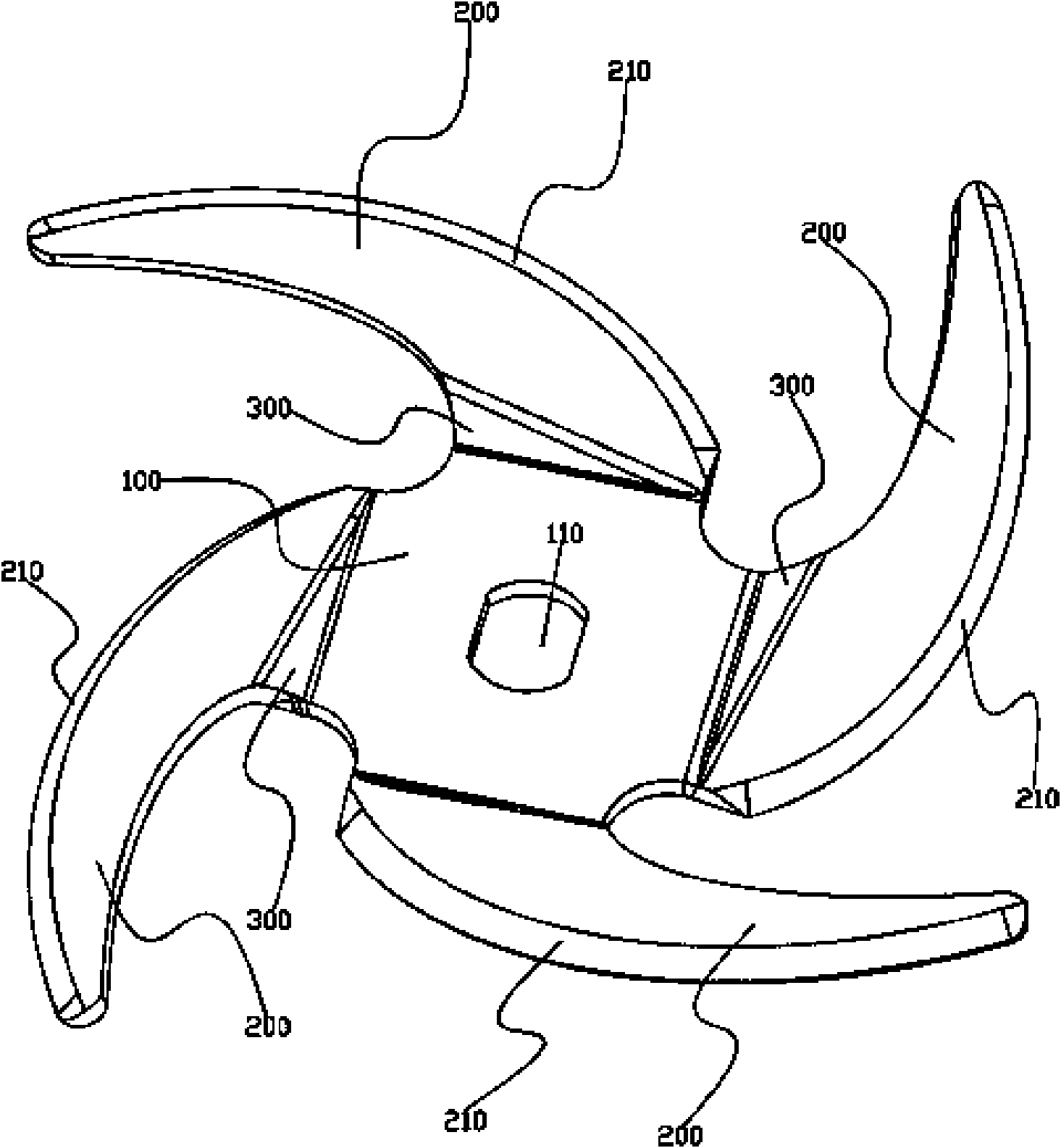

[0026] Please check figure 2 , image 3 and Figure 4 , a rotary cutter for a food processor, which includes a knife seat 100 and a plurality of knife blades 200 fixed to the knife seat 100 in an annular arrangement, wherein: the knife blades 200 are fixed on the knife seat 100 through a knife base 300; A rectangular hole 110 is defined on the tool seat 100 for connecting the output shaft of the electric mechanism so that the rotary tool can follow the rotation of the output shaft of the electric mechanism.

[0027] In this embodiment, the number of the blades 200 is four, but it is not limited thereto, other such as two, three, five, etc. can also be applied to this embodiment. In this embodiment, the knife seat 100 is selected as a square block, but it is not limited thereto, and other such as round blocks are also applicable to this embodiment. In this embodiment, the blade 200 is chosen to be horn-shaped, but it is not limited thereto.

[0028] Each blade 200 has a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com