Method and device for measuring crushing degree of tobacco shreds

A technology of crushing device and crushing strength, applied in the field of tobacco processing, can solve the problems of large sampling volume, destroying the structure of cut tobacco, waste of cut tobacco, etc., and achieving the effects of small sampling volume, simple operation and good method reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

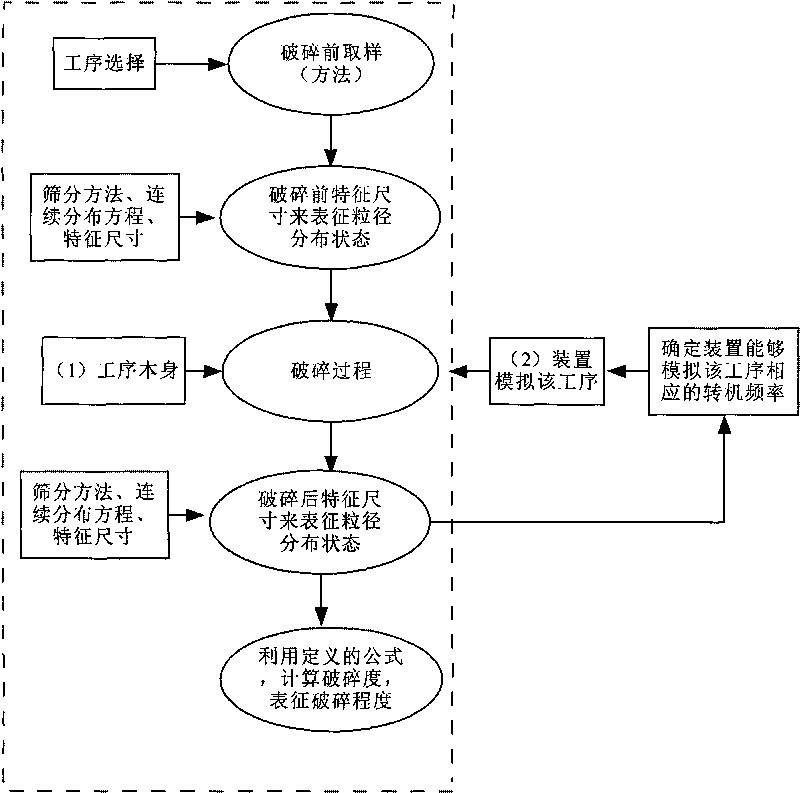

Method used

Image

Examples

Embodiment Construction

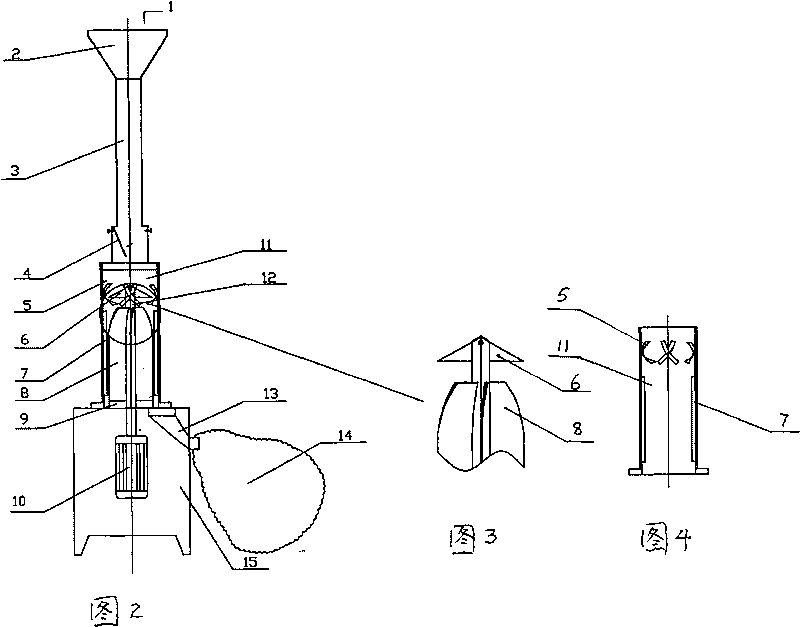

[0048] The crushing device of the present invention will be further described below in conjunction with the accompanying drawings:

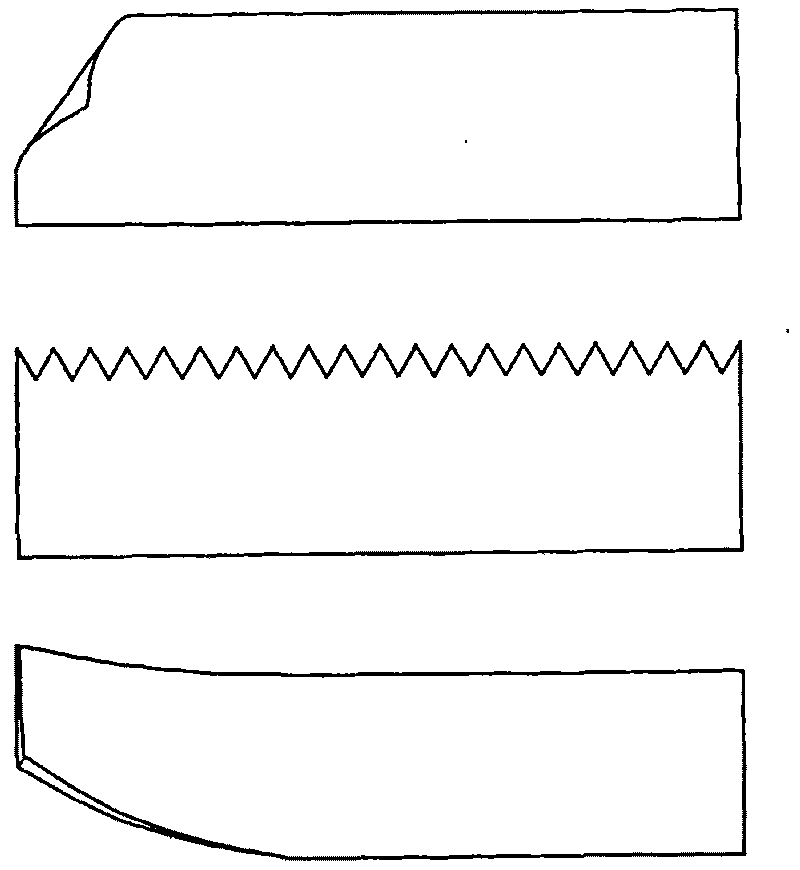

[0049] like figure 2 , 3 , shown in 4: crushing device of the present invention comprises feeder and shredded tobacco crushing cavity 11, and feeder is a cylindrical shape limiting tube 3 with feeding funnel 2 at the top, and the diameter of limiting tube is 1 / 2 of the crushing cavity diameter, The length exceeds 15cm; the crushing cavity 11 is an upright circular cavity structure, made of smooth transparent material, the limiting tube is vertically set up above the crushing cavity and communicates with the crushing cavity, the blanking flap 4 is set in the limiting tube, and the blanking The opening adjustment range of the flap is 0-90°. Along the central axis of the crushing chamber, a rotating shaft 12 driven by a motor 10 is arranged. , four strips 8 are evenly arranged along the rotating shaft, and the strip shape can be Figure 5 For an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com