Small-range tunnel horizontal plane model tester system for realizing multistage and master control loading

A model test device and small-scale technology, which is applied in the direction of measuring devices, testing of machines/structural components, and measurement of elastic deformation force through measuring gauges, etc. Problems such as lateral loading can be achieved to solve loading failure, reduce friction, and produce economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

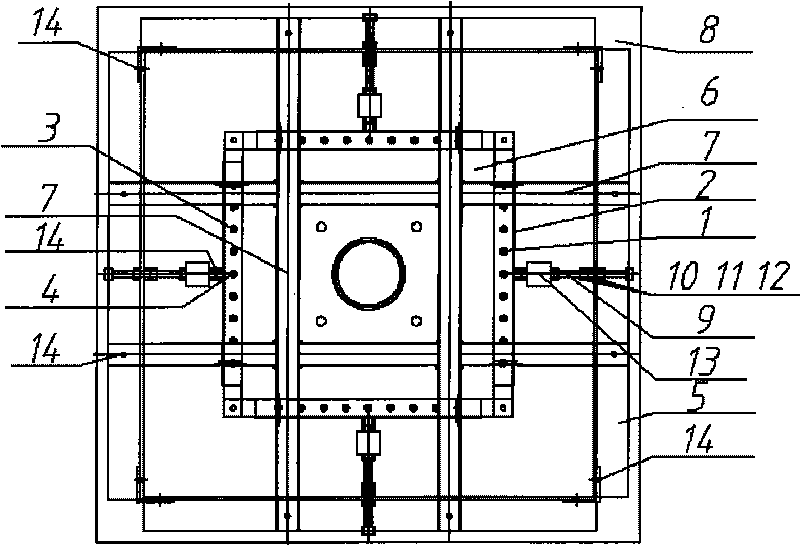

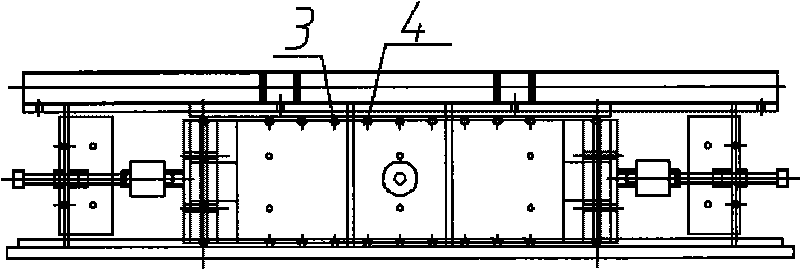

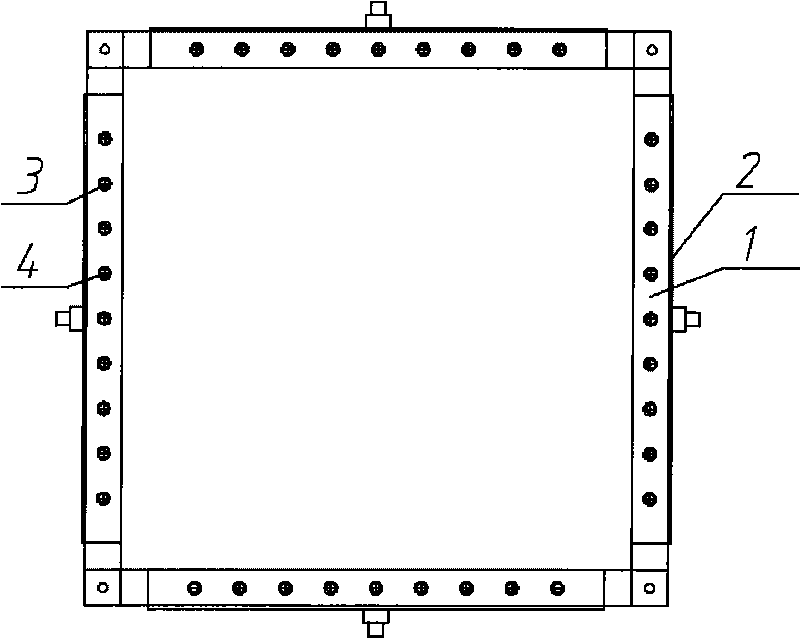

[0032] like Figure 1-2 As shown, it is the plan view of the overall structure of the present invention and the schematic diagram of the overall elevation, including the model loading inner frame A that realizes direct application and transfer of loads, the outer frame B of the reaction frame that provides test reaction force support, and the mechanical engagement jacking of bolts And cooperate with the high-sensitivity tension and pressure sensor to measure the combined loading device C.

[0033] Among them, the loading inner frame A includes wooden board 1, steel plate 2, steel ball 4 with anti-friction treatment, self-locking screw 3, and the outer frame B of the reaction force frame includes section steel 5, plexiglass cover plate 6, well-shaped square steel pipe 7, bottom The loading plate 8 and the loading device C include a loading bolt 9 , a high-strength load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com