Tool platform for assembling drum-shaped complex joints and using method of tool platform

A node and drum-shaped technology, which is applied in the direction of workbench, manufacturing tools, hand-held tools, etc., can solve the problems of central pipe fixing trouble, high dependence on total station, and high requirements for assembly site, so as to achieve cost saving and assembly principle The effect of simplicity and low requirements on site conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated by specific examples below.

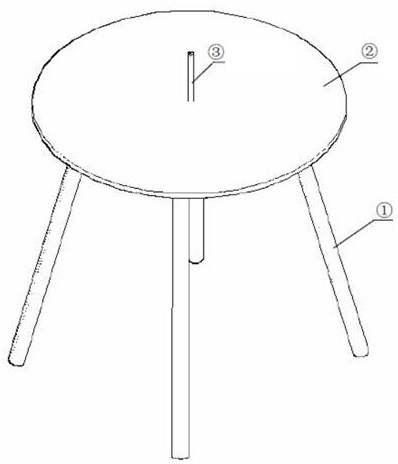

[0024] like figure 1 As shown, a tooling platform for drum-shaped complex node assembly includes outriggers (1), platform plates (2), and fixing bolts (3). It is arranged on the bottom surface of the platform plate (2), and a fixing bolt (3) is arranged in the center of the platform plate (2).

[0025] In the tooling platform used for the assembly of drum-shaped complex nodes, the platform plate (2) is arranged horizontally, and the platform plate (2) is 90 cm to 120 cm from the bottom surface.

[0026] In the tooling platform for assembling drum-shaped complex nodes, there are four outriggers (1) and are arranged on the bottom surface of the platform plate (2) in the shape of a quadrangular pyramid.

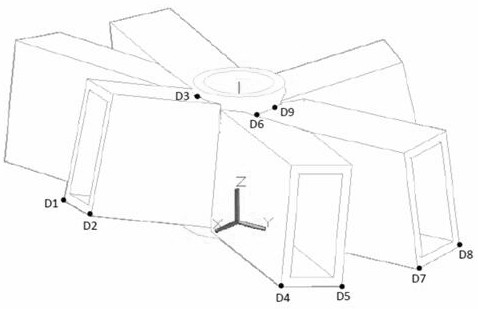

[0027] like Figure 2~Figure 5 As shown, the use process of this tooling platform is as follows:

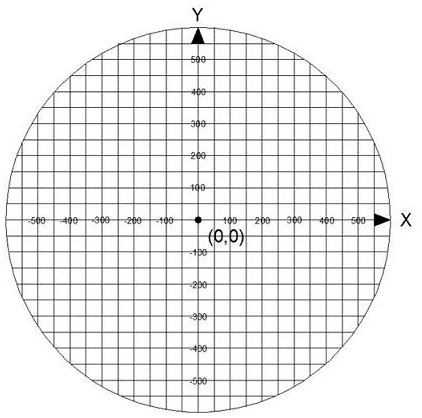

[0028] Step 1. Draw a cross line with the center of the platform board as the midpoint, and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com