Punch die module of stator punching sheet

A technology of stator punching and punching die, which is applied in the manufacture of stator/rotor body, etc., which can solve the problems of adverse effects on motor performance, increased core loss, labor and time-consuming cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

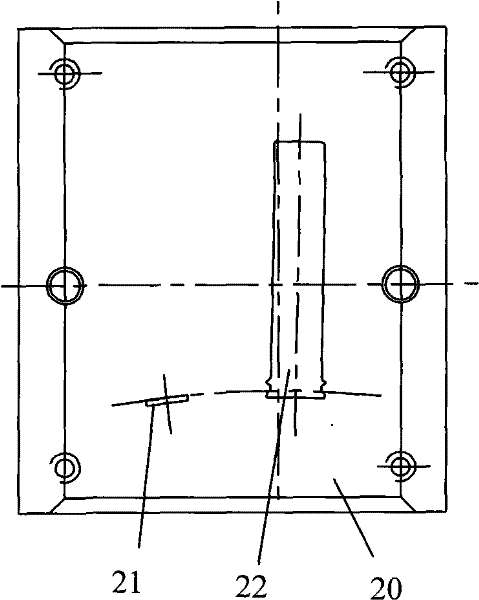

[0018] The stator stamping die module of the present invention includes an upper module and a lower module 20 .

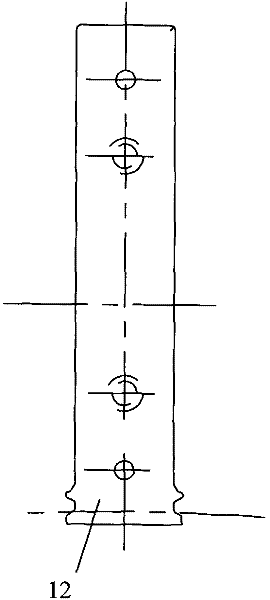

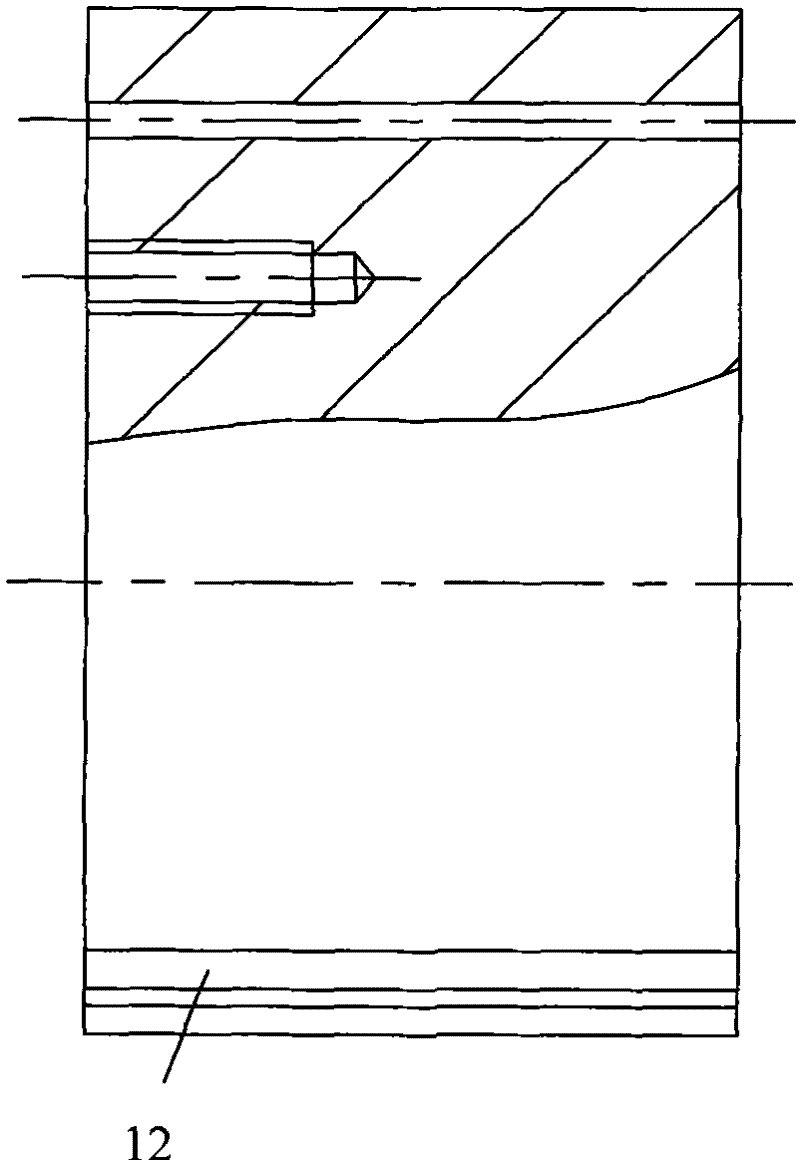

[0019] Among them, such as Figure 2 to Figure 5 As shown, the upper module is divided into a cutting punch 11 and a groove punch 12. And as figure 1 As shown, the lower module 20 has a cutting die 21 and a groove-shaped die 22 .

[0020] Please refer to figure 1 and figure 2 Shown, the cross-section of the grooved punch 12 and the grooved die 22 are rounded at the two corners of the bottom, such cross-sectional shape makes the notch angle of the stator groove 301 punched out be rounded (as Figure 7 shown). recombine figure 1 and Figure 5 As shown, the shape of the slitting punch 11 and the slitting die 21 is a flat rectangular shape.

[0021] Another example figure 1 As shown, the slitting die 21 and the groove-shaped die 22 (viewed from the upper module, that is, the slitting punch 11 and the groove-shaped punch 12) are separated by a certain distance...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap