A high-speed punching machine for motor iron core processing

A high-speed punching and iron core technology, applied in metal processing equipment, manufacturing motor generators, manufacturing tools, etc., can solve the problems of reducing punching efficiency, inconvenient use, complicated steps, etc. The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

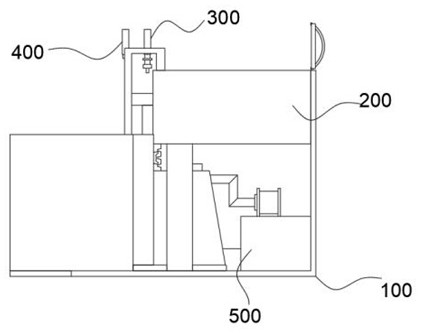

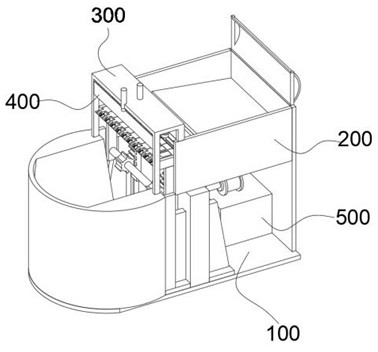

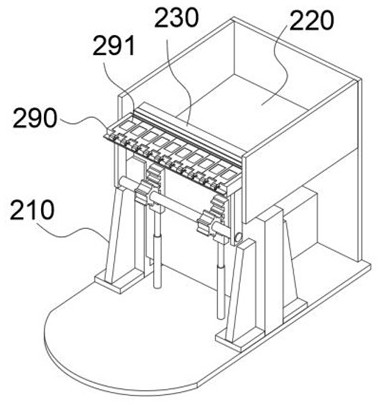

[0047] combine Figure 1-Figure 10As shown, the present invention provides a high-speed punching machine for motor iron core processing, including an L-shaped substrate 100, and the L-shaped substrate 100 is provided with a feeding module 200, a punching module 300 and a discharging module 400. The loading module 200 includes two brackets 210 connected to the top of the L-shaped substrate 100 , a U-shaped plate 220 connected between the L-shaped substrate 100 and the two brackets 210 , and the outer wall of the U-shaped plate 220 . The lifting plate 230 frictionally and slidingly connected between the two brackets 210, the two limiting plates 240 located at the bottom of the U-shaped plate 220 and connected to the inner side of the lifting plate 230, and slidingly installed on the two The rotating rod 250 between the limit plates 240 , the motor 260 whose output shaft is connected to the rotating rod 250 , the baffle plate 270 rubbing against the outer wall of the lifting plat...

Embodiment 2

[0056] combine figure 1 , figure 2 and Figure 10 As shown, on the basis of the first embodiment, the L-shaped substrate 100 is further provided with a recycling module 500, and the recycling module 500 includes a belt conveyor 510 connected to the top of the L-shaped substrate 100 and a belt conveyor 510 connected to the L-shaped substrate 100. The frame body 520 connected to the top of the shaped base plate 100, the belt conveyor 510 is located between the two cylinders 294, one end of the belt conveyor 510 extends to the inside of the frame body 520, the bottom of the motor 260 is connected to the top of the frame body 520, The recycling module 500 can collect the unprocessed parts that have slipped from the flushing box 290, and play the role of recycling the parts.

Embodiment 3

[0058] combine Figure 4 , Figure 5 and Figure 8 As shown, in the above embodiment, a metal rod is provided on the cloth tape 280, the metal rod is located at the center of the cloth tape 280, the length of the metal rod is equal to the cloth tape 280, and the metal rod is used to guide the cloth tape 280 , when the cloth belt 280 is loosened, the metal rod presses the middle of the cloth belt 280 downward to prevent the cloth belt 280 from wrinkling between the punching box 290 and the baffle 270 .

[0059] The working principle and use process of the present invention: in the initial state, a large number of iron cores to be processed are placed in the placement cavity, and then when the present invention is put into practical use, the motor 260 is started to make the rotating rod 250 rotate. The lift plate 230 will complete a lift, wherein, each time the lift plate 230 rises, it will lift up with a part of the iron core, the iron core is attached to the baffle 270, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap