Prebending device

A pre-bending and pre-bending technology, which is applied in the field of pre-bending devices for asymmetric section steel, can solve the problems of heavy pre-bending workload, increased production costs, increased equipment costs, etc., and achieves long service life and improved work efficiency , focus on reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

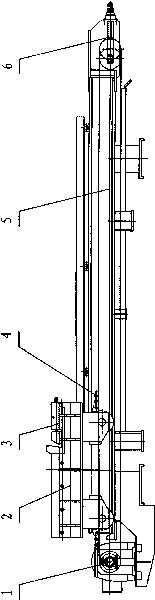

[0021] Such as figure 1 , figure 2 , image 3 As shown, a kind of pre-bending device comprises several pre-bending units arranged side by side, and each pre-bending unit includes a pre-bending dolly 2 with a pre-bending head 3, and each pre-bending unit passes the pre-bending dolly by a chain 4 2. The position-controllable transmission device 1 and the tension mechanism 6 are integrated into one body. The position-controllable transmission device 1 and the tension mechanism 6 are fixed on the frame 5. When the position-controllable transmission device 1 is working, the chain 4 Drive the pre-bending trolley 2 to move on the frame 5;

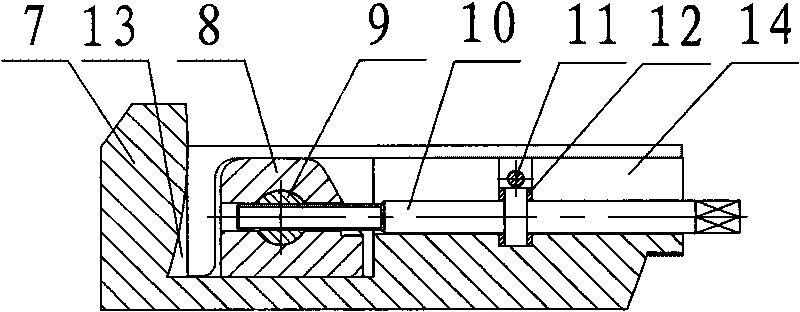

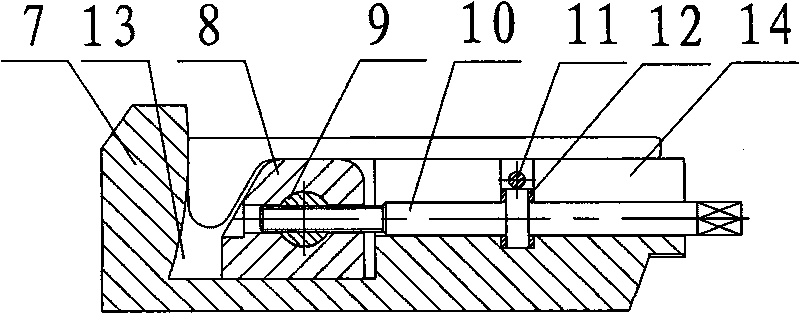

[0022] The pre-bend 3 is mainly composed of a fixed block 7, a movable block 8 and an adjusting screw 10;

[0023] The inside of the movable block 8 is equipped with a fixed nut 9, and one end of the adjusting screw 10 is connected to the movable block 8 by the fixed nut 9; Matching circular groove 14, the adjustment screw 10 is placed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com