Drum washing machine

A technology for drum-type washing machines and washing drums, which is applied to other washing machines, washing machines with containers, washing devices, etc., and can solve the problems of widening front width of drum-type washing machines, inability to realize miniaturization, increased vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

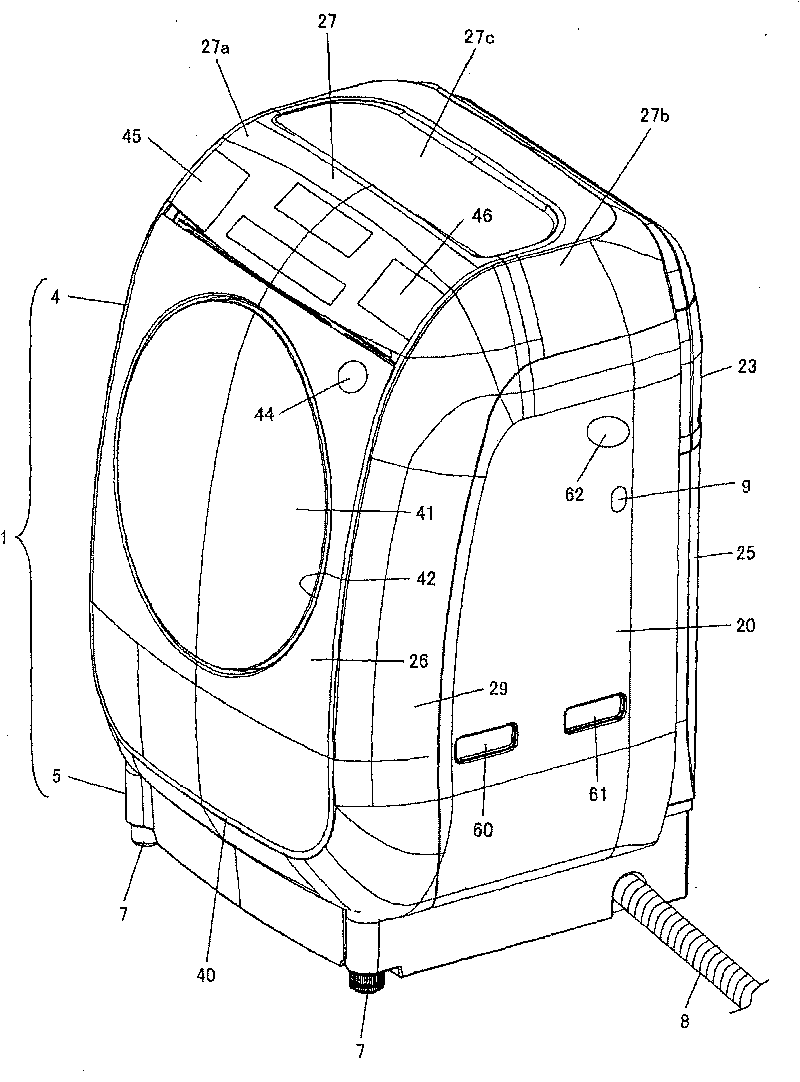

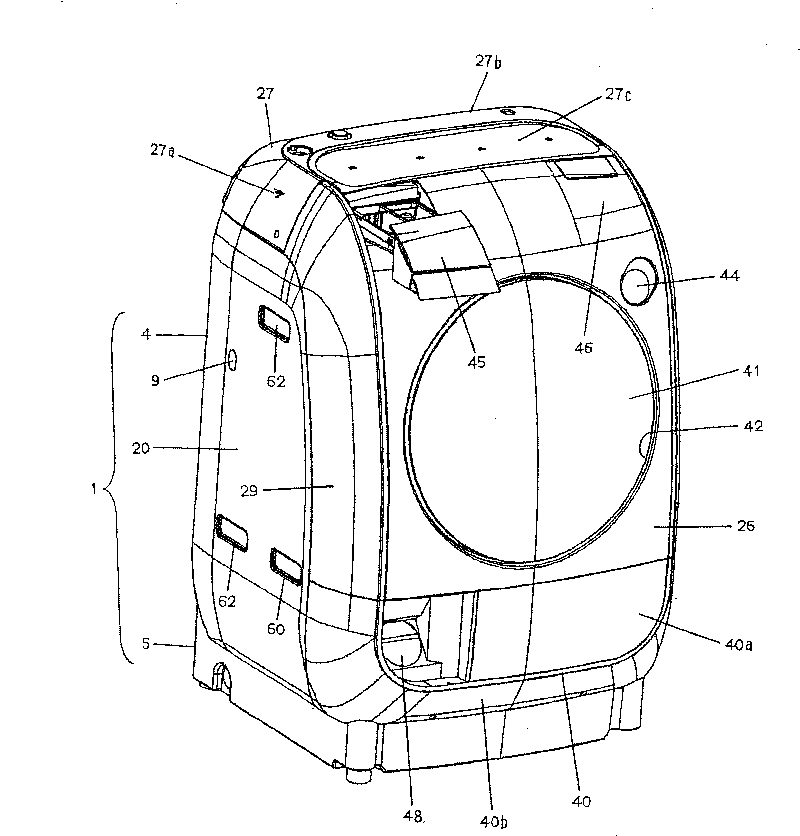

[0043] Such as figure 1 , Figure 5 to Figure 9 As shown, the drum type washing machine has an outer frame cabinet 1, an outer cylinder 2 placed in the outer frame cabinet 1, and a freely rotatable washing drum 3 inside the outer cylinder 2. The outer cylinder 2 is anti-vibration supported by an anti-vibration support mechanism.

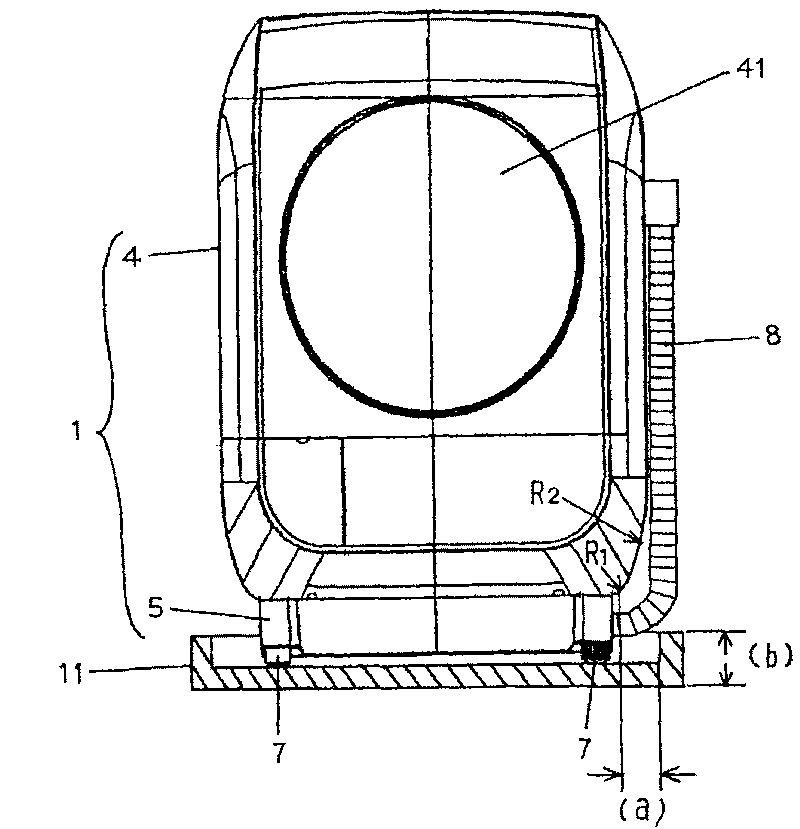

[0044] The outer frame cabinet 1 has a cabinet main body 4 and a base 5 on which the cabinet main body 4 is placed. The base portion 5 is formed of synthetic resin. Such as Figure 10 It is shown with a plurality of lattice-like reinforcing structures 6 . Support legs 7 are provided at four corners of the bottom surface of the base portion 5 .

[0045] The front width and depth width of the base portion 5 are made smaller than the front width and depth width of the outer frame housing 1 .

[0046] That is, the front width of the outer frame cabinet 1 is increased by increasing the diameter by an amount corresponding to the reduction in the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com