Electrical connector and sealing ring thereof

A technology of electrical connectors and sealing rings, which is applied in the field of sealing rings and can solve problems such as easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

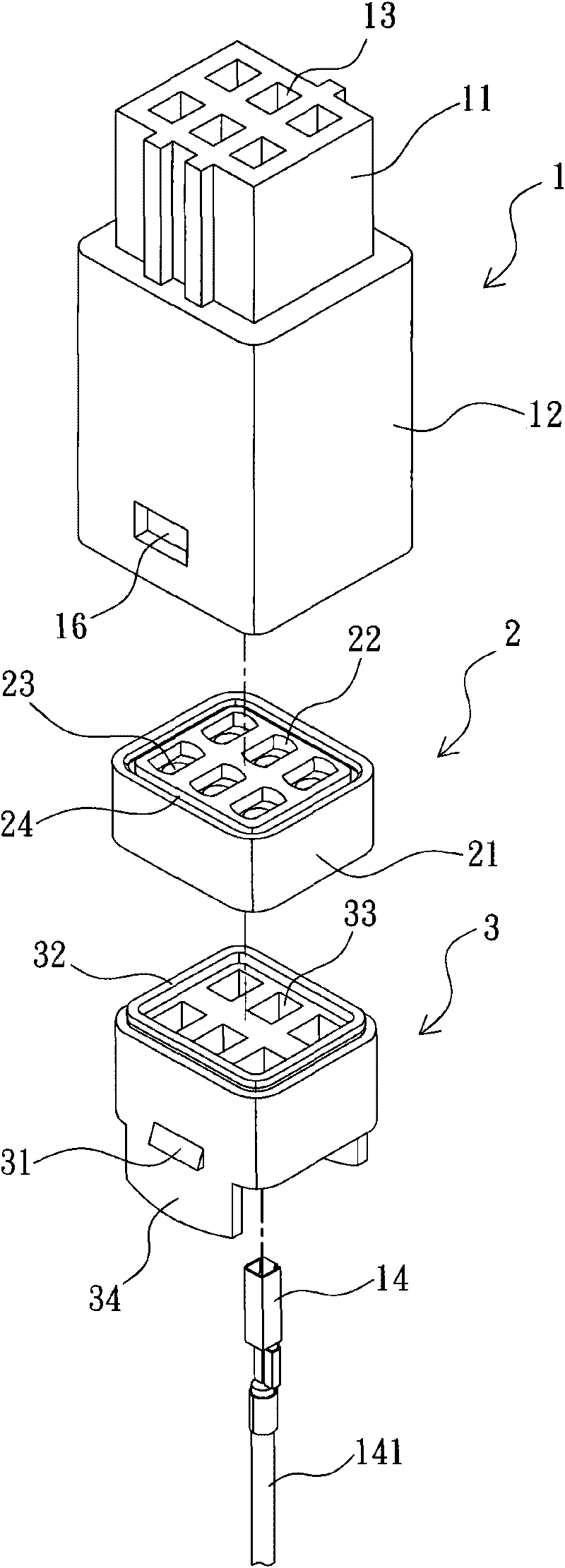

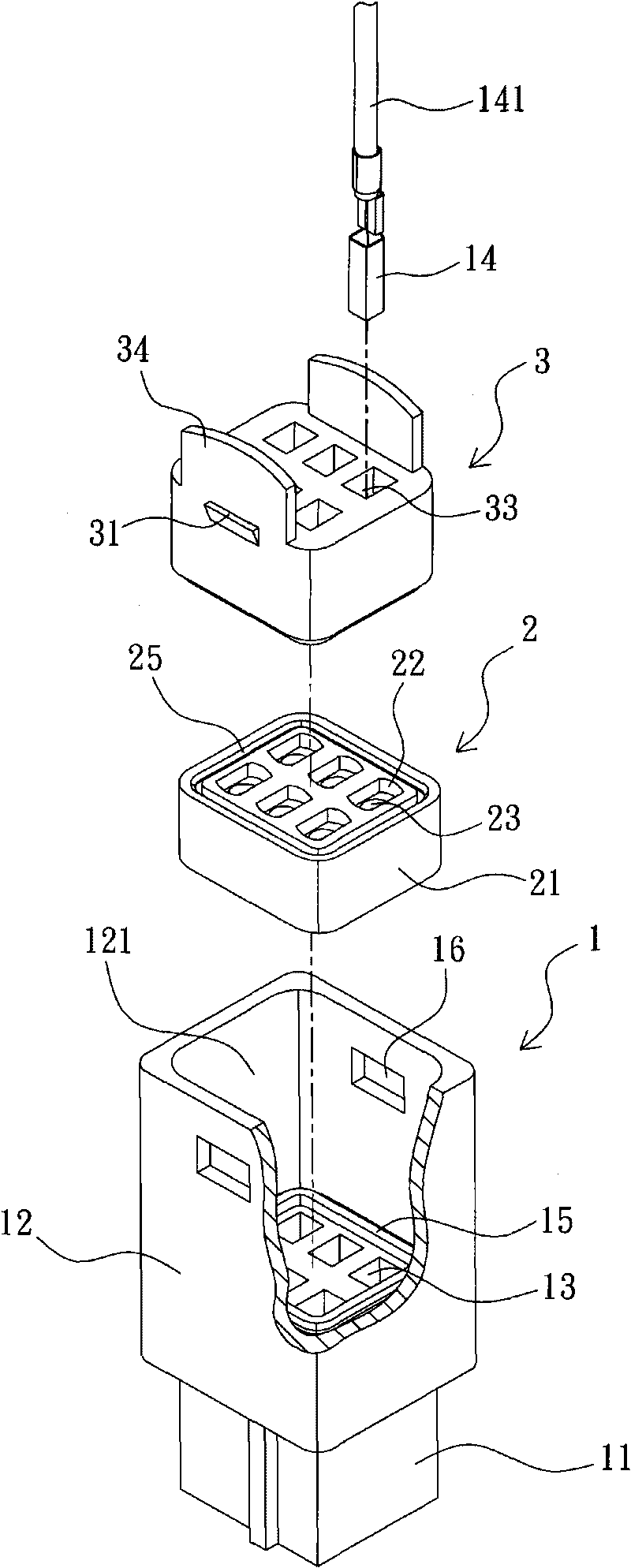

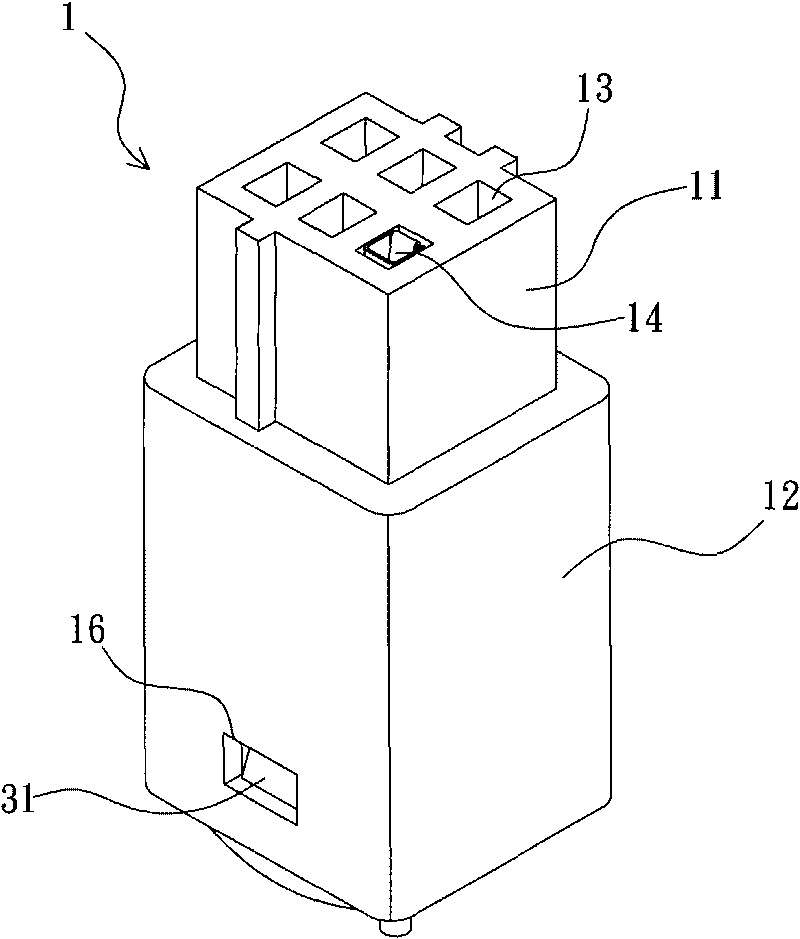

[0041] Such as Figure 1a to Figure 3b As shown, basically, the first embodiment of the electrical connector of the present invention is composed of a housing 1 , a sealing ring 2 , and a grid member 3 .

[0042] Wherein, the casing 1 is made of insulating material, such as plastic, and its upper section has a joint portion 11, and the lower part of the joint portion 11 is integrally connected with a larger skirt portion 12, and an accommodating space 121 is provided inside the skirt portion 12. , so as to accommodate and lock the sealing ring 2 and the grille 3 for the latter. The joint part 11 is used for docking with another electrical connector. Therefore, the joint part 11 axially defines more than one terminal slot 13 communicating with the accommodating space 121 for the terminals 14 to be accommodated and positioned. The wire 141 of 14 passes through the sealing ring 2 and the grid part 3 . In addition, an annular first positioning flange 15 protrudes from the top in...

Embodiment 2

[0051] Such as Figure 4 to Figure 6b As shown, the second embodiment of the electrical connector of the present invention is composed of a housing 1 , a sealing ring 2 , and a grid member 3 .

[0052] Wherein, the structures of the housing 1 and the grille 3 are the same as those of the first embodiment, and will not be repeated here.

[0053] The sealing ring 2 is different from the first embodiment in that at least one external convex rib 27 protrudes from the circumferential surface of the plug connector 21 of the sealing ring 2, such as Figure 4 As shown, it is preferable to protrude outwardly protruding ribs 27 on the peripheral surface of the plug connector 21 adjacent to the top end and the bottom end respectively. The outer side of the annular opening of the first and second circumferential positioning grooves 24, 25 radially forms a guide slope 28 inwardly, which facilitates the guiding of the positioning flanges 15, 32 into the corresponding first and second circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com