Multilayer beam type piezoelectric generator and power generation method thereof

A generator and piezoelectric technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of low piezoelectric conversion efficiency, small load capacity and charge Small problems, to achieve the effect of improving piezoelectric conversion efficiency, reducing power generation consumption, and large charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

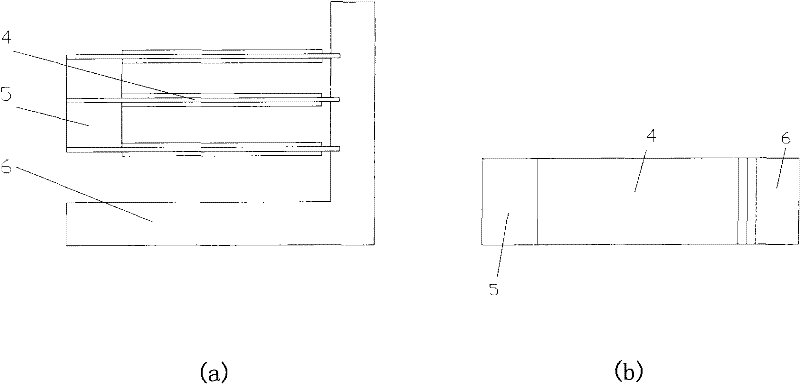

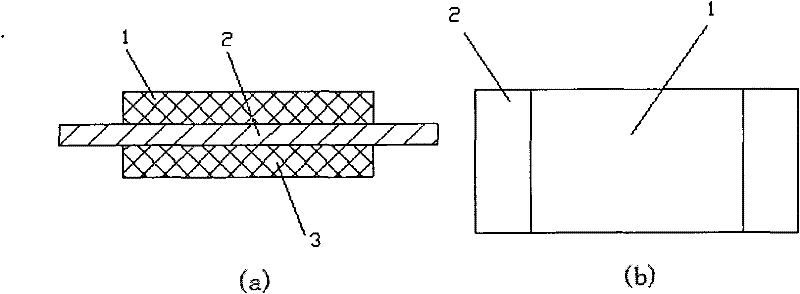

[0031] Figure 1~2 Shows the specific structure diagram of this embodiment, the multilayer beam piezoelectric generator includes several piezoelectric composite plates 4, such as figure 2 As shown in (a), each piezoelectric composite plate 4 includes piezoelectric elements 1, 3 and an elastic metal body 2. The piezoelectric elements 1, 3 are respectively connected to the upper and lower surfaces of the elastic metal body 2; figure 1 As shown, one end of the piezoelectric composite plate 4 is fixedly connected with the frame 6 and the other end is rigidly connected with the force transmission block 5, and each piezoelectric composite plate is rigidly connected by the force transmission block.

[0032] Such as figure 1 As shown, a number of piezoelectric composite plates 4 are fixed on the frame 6 along the thickness direction to form a piezoelectric composite plate beam group; the number of piezoelectric composite plate beam groups is a group, and is fixed to the frame 6 Above, ea...

Embodiment 2

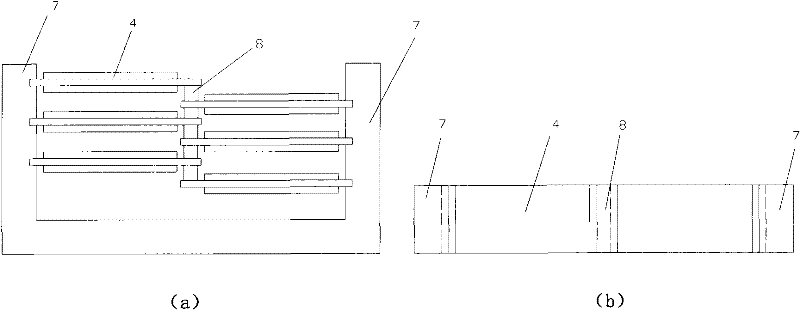

[0037] This embodiment is the same as embodiment 1 except for the following features: image 3 As shown in (a), the plurality of piezoelectric composite plates 4 are fixed on the frame 7 along the thickness direction to form a piezoelectric composite plate beam group; the piezoelectric composite plate beam group is in several groups, and each piezoelectric composite plate The beam groups are centered on the force transmission block 8 and are symmetrically fixed on the frame 7 on both sides, and the piezoelectric composite plates are distributed in a rectangular parallelepiped array. Such as image 3 As shown in (b), the piezoelectric composite board 4 has a trapezoidal structure, that is, both the piezoelectric element and the elastic metal body are rectangular structures.

Embodiment 3

[0039] This embodiment is the same as embodiment 1 except for the following features: Figure 4 As shown in (b), the piezoelectric composite plate 9 has a trapezoidal structure, in which the piezoelectric element and the elastic metal body are both trapezoidal structures, and the piezoelectric element is polarized in the thickness direction.

[0040] Such as Figure 4 As shown in (a), the plurality of piezoelectric composite plates 9 are fixed on the frame 10 along the thickness direction to form a piezoelectric composite plate beam group; the piezoelectric composite plate beam group is in several groups, and each piezoelectric composite plate The beam groups are centered on the force transmission block 11 and are evenly fixed on the surrounding frame 10, and the piezoelectric composite plates are distributed in a regular triangular prism array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com