Device for maintenance of the metal belt

A technology of metal belt and clamping device, which is applied in the direction of textiles and papermaking, paper machine, paper machine wet end, etc., can solve problems such as difficulty in realization, and achieve the effect of avoiding cooling time and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

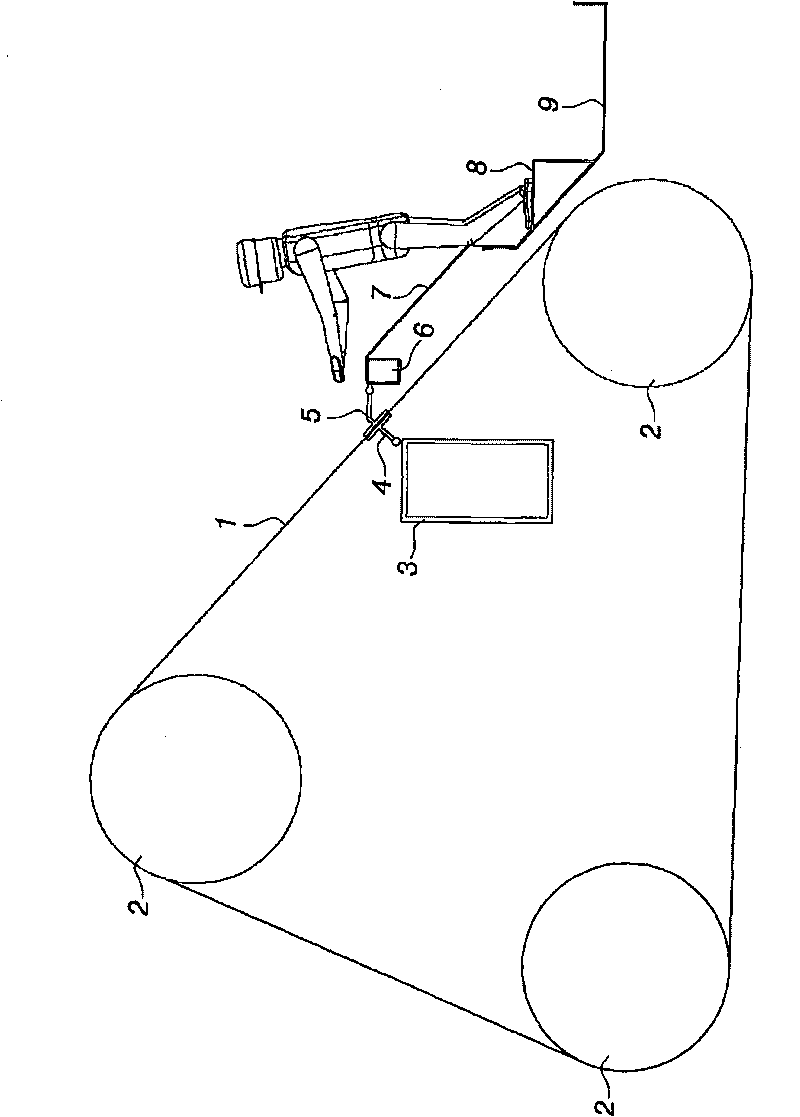

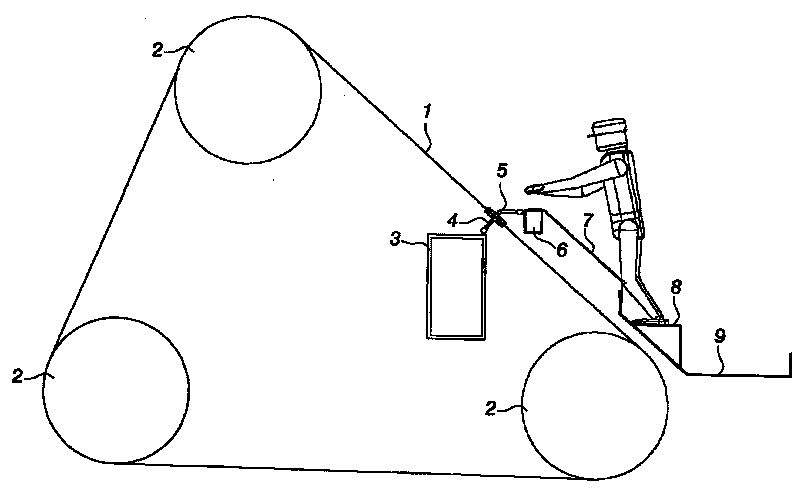

[0011] figure 1 An endless metal belt 1 circulating around a plurality of guide rollers 2 is shown in . Inside the belt loop there is a transverse support member, such as a beam 3, along which a movable repair support 4 is arranged. The repair support is preferably made of a non-solderable material such as copper or aluminium, but it can also be made of a weldable material which is preferably provided with a non-solderable protective layer on its surface facing the metal strip. The protective layer can be formed, for example, from a film or sheet metal, or it can be designed as a coating. The control of the metal strip 1 is arranged such that the part of the metal strip to be repaired is automatically or manually guided to or remains at the position of the transverse support member 3 in the forward direction of the metal strip. The repair support 4 is then moved along said transverse support member 3 to the position of the part of the metal strip to be repaired so that the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap