Construction method of composite foundation

A construction method and technology for composite foundations, which are applied in basic structure engineering, soil protection, construction, etc. to achieve the effects of large power, uniform settlement, and uniform bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

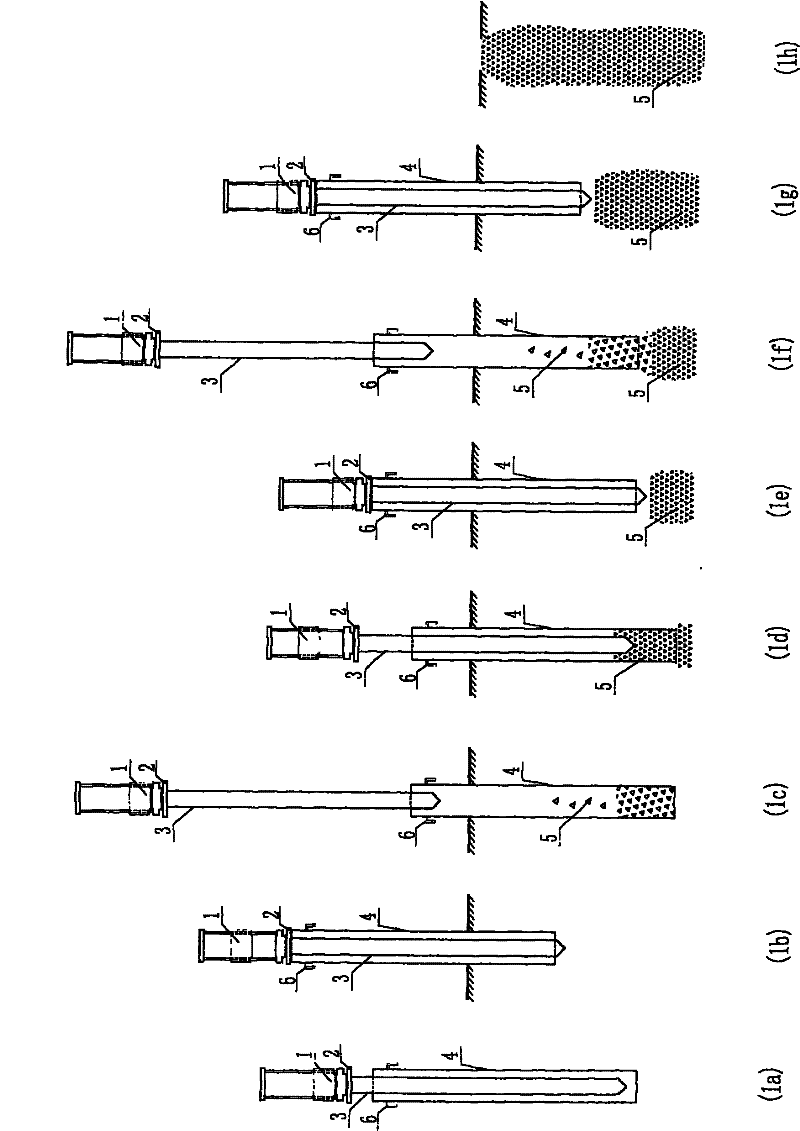

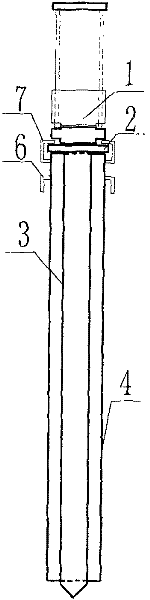

[0028] exist figure 1 In the shown embodiment, according to the construction method of composite foundation of the present invention, as figure 1 As shown in a, first connect the special upper end to the internal ramming tube 3 that fixes the diesel hammer 1 and the ramming plate 2, and insert it into the large-diameter outer tube 4. Such as figure 1 As shown in b, through the up and down action of the diesel hammer 1, the tamping plate 2 hits the outer tube 4, so that the outer tube 4 and the inner ramming tube 3 sink downward at the same time to the design depth. Such as figure 1 As shown in c, the above-mentioned internal ramming tube 3 is proposed, and a certain amount of bulk filler 5 is filled into the inner bottom of the outer tube 4 . Such as figure 1 As shown in d, the inner ramming tube 3 is inserted into the outer tube 4, and the internal ramming tube 3 rams the filled bulk filler 5 through the up and down action of the diesel hammer 1, and the filler 5 is gradu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com