Magnetic field shielding device of high-temperature superconducting coil

A high-temperature superconducting and shielding device technology, applied in superconducting magnets/coils, magnetic field/electric field shielding, coil manufacturing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

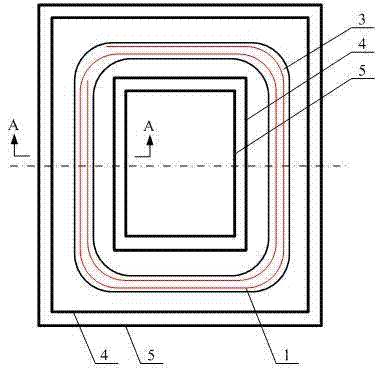

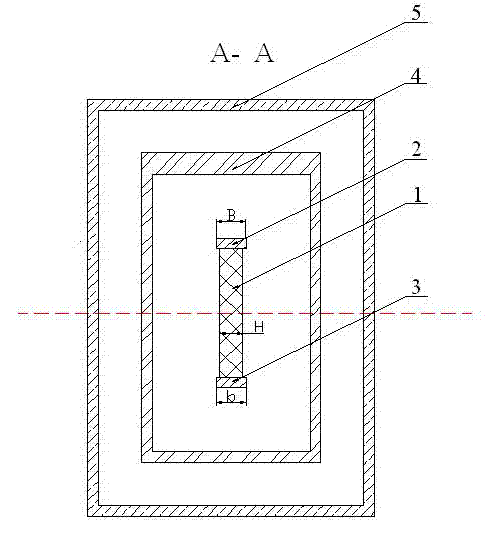

[0008] Specific implementation mode 1: the following combination figure 1 , figure 2 , Figure 5 , Image 6 with Figure 7 This embodiment will be described in detail. The magnetic field shielding device of the high-temperature superconducting coil includes a cryostat 4 and a vacuum container 5. The high-temperature superconducting coil 1 is fixed in the cryostat 4, the cryostat 4 is fixed in the vacuum container 5, and the cryostat 4 communicates with Into liquid nitrogen, it also includes a first magnetic sheet 2 and a second magnetic sheet 3. The first magnetic sheet 2 is fixed above the axial direction of the high-temperature superconducting coil 1, and the second magnetic sheet 3 is fixed on the high-temperature superconductor. Below the coil 1 in the axial direction, the width B of the first magnetic conductive sheet 2 and the width b of the second magnetic conductive sheet 3 are both 1.1 to 1.5 times the thickness H of the high temperature superconducting coil 1.

[0009...

specific Embodiment approach 2

[0016] Specific implementation manner 2: the following combination figure 2 This embodiment will be described in detail. The difference between this embodiment and the first embodiment is that the first magnetic sheet 2 is fixed on the upper end of the high-temperature superconducting coil 1, and the second magnetic sheet 3 is fixed on the lower end of the high-temperature superconducting coil 1.

specific Embodiment approach 3

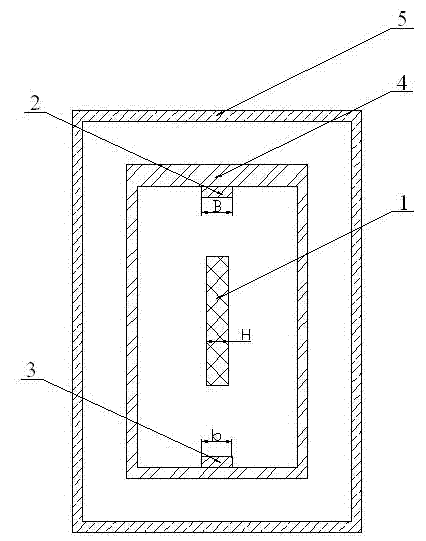

[0017] Specific implementation manner three: the following combination image 3 This embodiment will be described in detail. The difference between this embodiment and the first embodiment is that the first magnetic sheet 2 is fixed on the inner surface above the cryostat 4 shell, and the second magnetic sheet 3 is fixed inside the cryostat 4 below the shell. On the surface.

[0018] Compared with the second embodiment, the thickness B of the first magnetic sheet 2 and the thickness b of the second magnetic sheet 3 can be increased by more than 50%. The thicker the thickness of the magnetic sheet, the more the surface of the high-temperature superconducting coil 1 The smaller the vertical magnetic field distribution, therefore, the shielding effect of the high-temperature superconducting coil magnetic field shielding device described in this embodiment in the axial direction of the high-temperature superconducting coil 1 is higher than that of the high-temperature superconducting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com