Bulk grain multi-storied warehouse with hollow pillars

A technology of hollow columns and buildings, applied in large-capacity bulk material storage, climate change adaptation, building types, etc., can solve problems such as unfavorable scattered operations and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

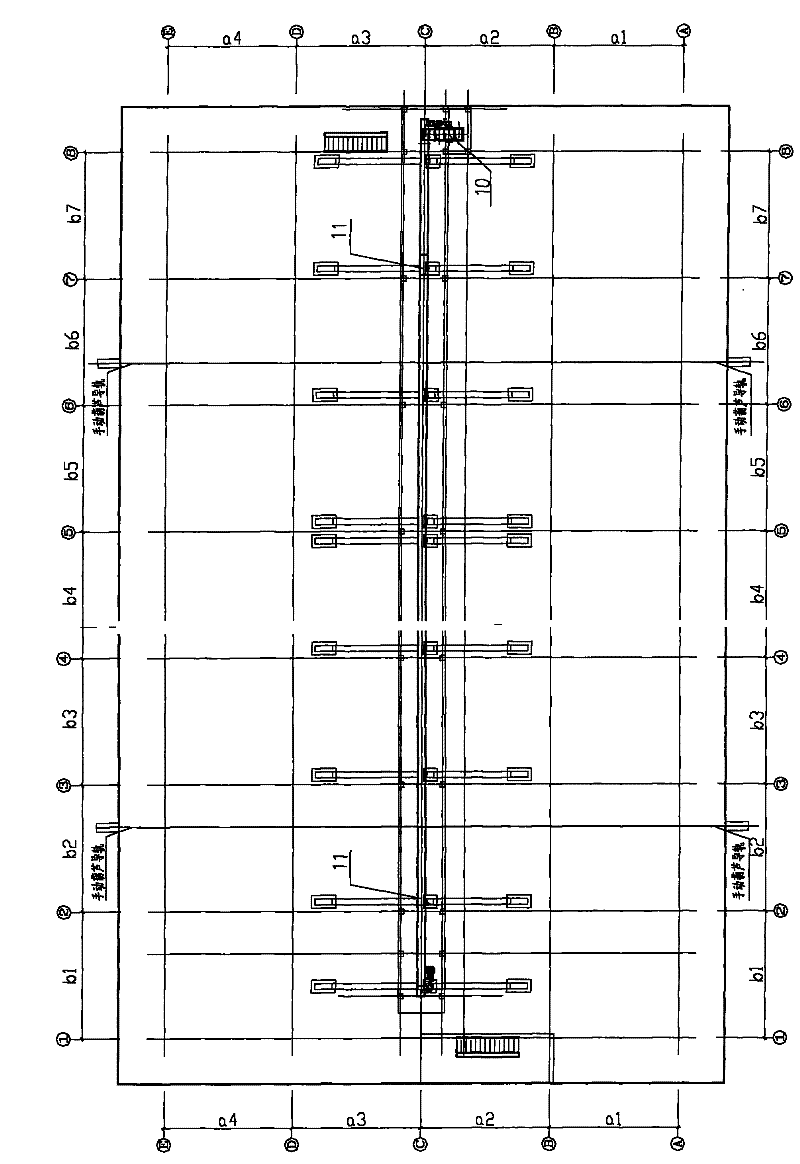

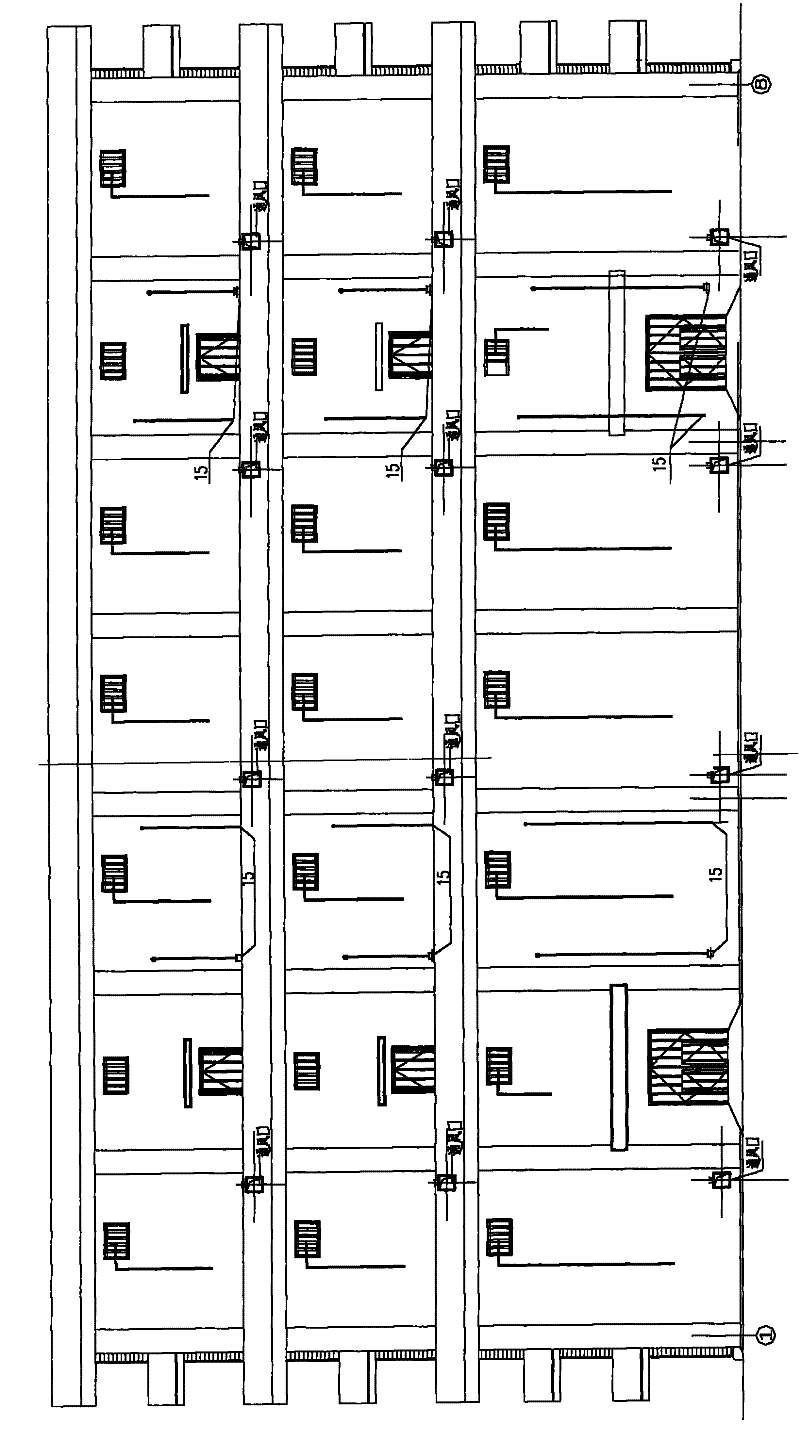

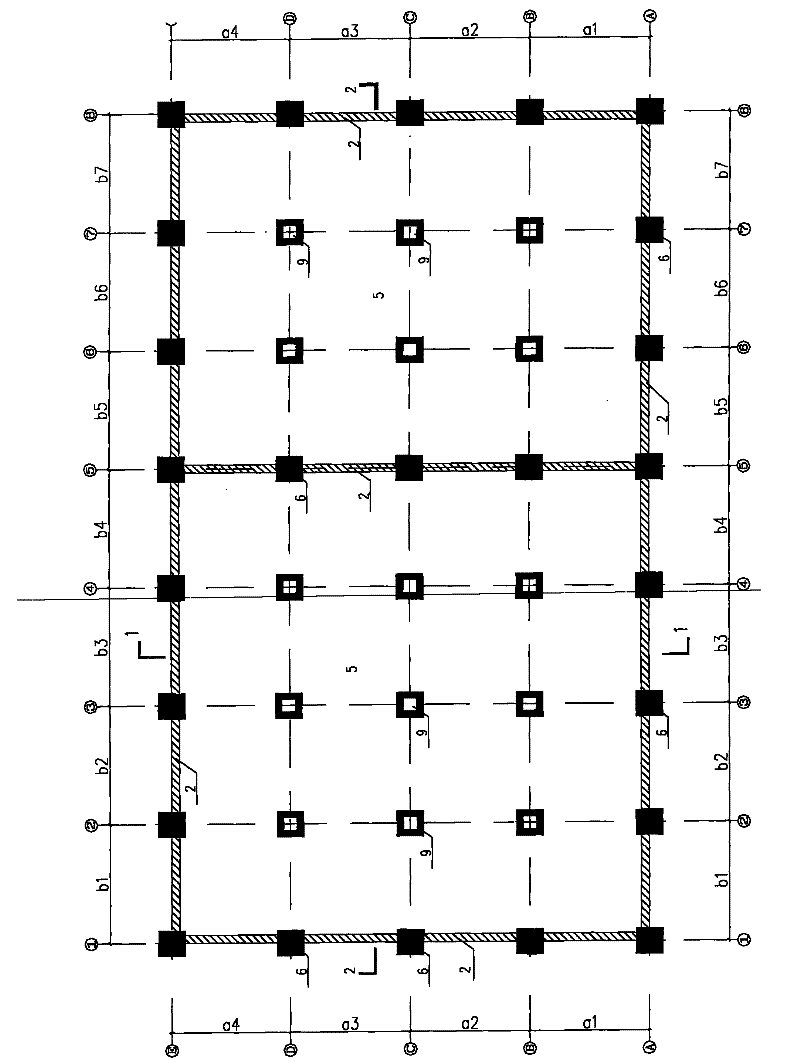

[0047] The present invention is a three-layer rectangular bulk grain building storehouse containing 15 hollow columns as shown in the accompanying drawing, and every layer contains two rooms, including storehouse bottom 1, storehouse wall 2, interlayer storehouse bottom plate 3, storehouse roof plate 4. Wherein the warehouse wall composite column 6 and the connecting beam 7 between the warehouse wall composite columns are set in the warehouse wall 2, and grain 17 is housed in the room 5.

[0048] The warehouse roof plate 4 transmits the load to the frame beam 8, and then the frame beam 8 to the hollow column 9 and the warehouse wall composite column 6, and then transmits the load to the foundation; the grain side pressure is first transmitted to the connection between the composite columns within the corresponding range The beam 7 is transmitted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com