Bulk grain building storehouse with prestressed hollow plate storehouse wall

A prestressing and building technology, applied in large-capacity bulk material storage, climate change adaptation, building types, etc., can solve problems such as low degree of automation, low utilization rate of warehouse capacity, unfavorable scattered operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

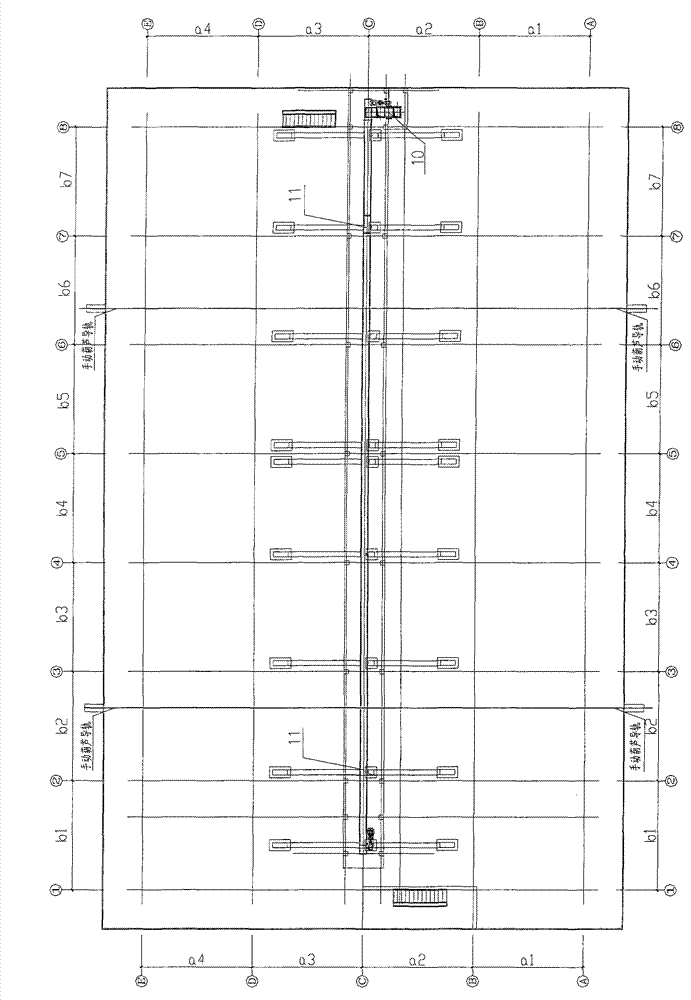

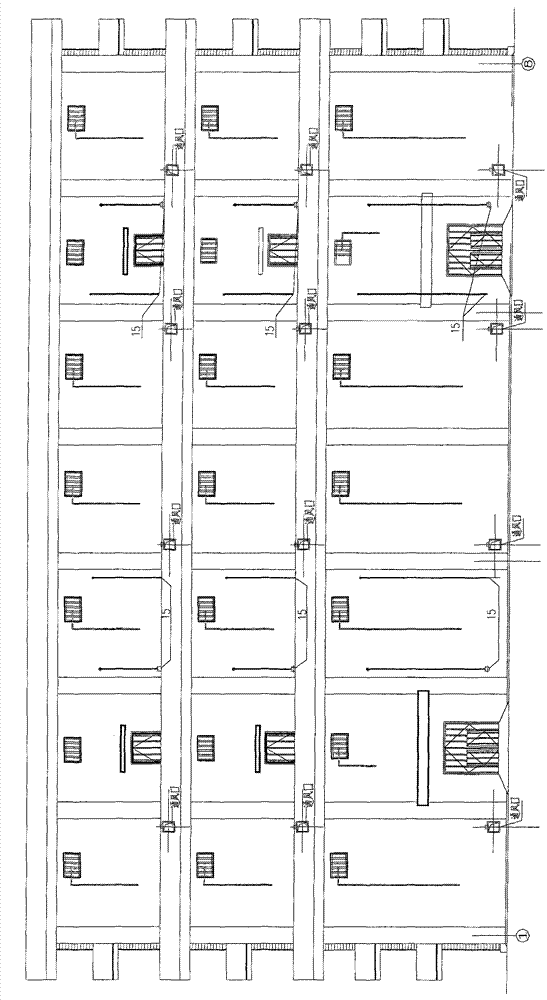

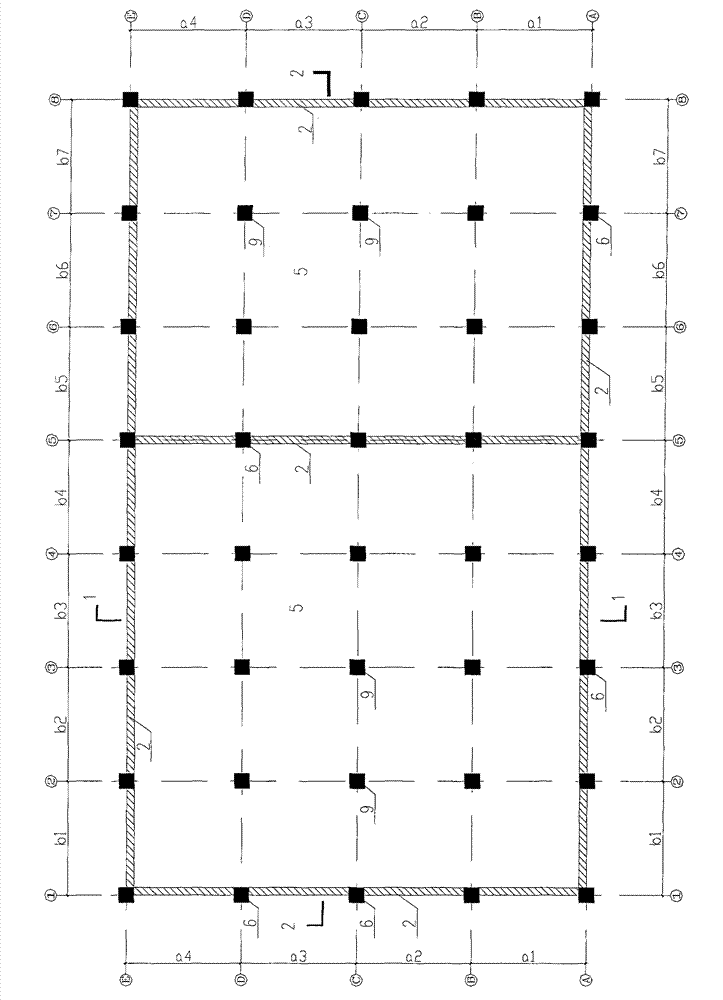

[0044] The present invention is a three-layer rectangular bulk grain building storehouse as shown in the accompanying drawing, and every layer contains two rooms, including storehouse bottom 1, storehouse wall 2, interlayer storehouse bottom plate 3, storehouse top plate 4. Wherein the warehouse wall 2 adopts the prestressed hollow concrete slab system, and the grain 17 is housed in the compartment 5 .

[0045] In order to prevent cracks that may appear on the surface of the prestressed hollow concrete slab 18 when it is placed sideways, non-prestressed structural steel bars should be provided on the non-prestressed side of the standard slab (that is, the side in contact with the grain) when the prestressed hollow concrete slab is manufactured. Cracks may develop.

[0046] Such as Figure 7 with Figure 8 As shown, in this example, two prestressed ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com