Method for automatic collocation and placement of material to be stringed, device, stringing mechanism and stick mechanism

A technology for placing devices and materials, which is applied in food science, slaughtering, meat processing equipment, etc., and can solve problems such as manual placement of materials, length limitation of sticks, damage to stringing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

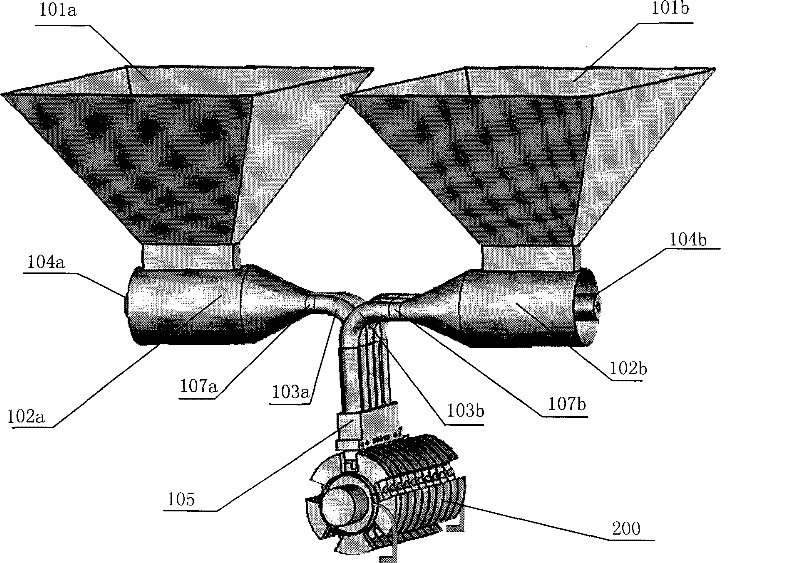

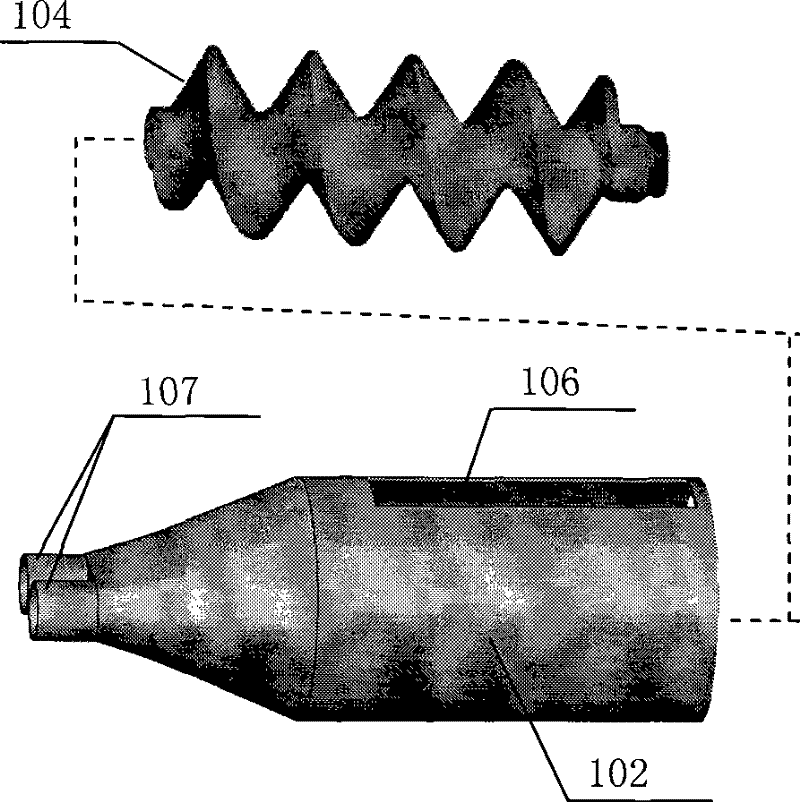

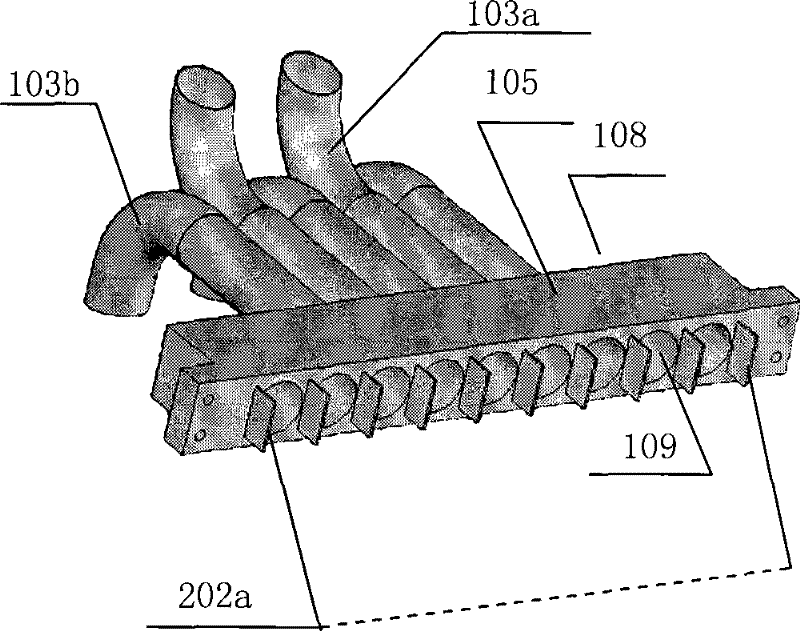

[0037] The automatic collocation and placement device provided by the present invention adopts the method of automatically collocating and arranging stringing materials, which is composed of a material classification component, a flow diversion mechanism, a collection and arrangement component, and a propulsion component. see figure 1 , the figure shows the main structure of the threading mechanism, and the upper part of the figure is a structural diagram of the automatic collocation and placement device. Depend on figure 1 It can be seen that what this figure shows is a threading mechanism with five pieces of materials on a stringing product and two varieties arranged alternately, that is to say, there are five Block materials and two varieties are arranged alternately. The sorting parts of the automatic collocation and placing device shown in this figure are composed of two hoppers 101; the flow diversion mechanism is composed of two flow distribution chambers 102 and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com