Accurate measurement device of powder

A powder, precise measurement technology, applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve the problems of not being widely used and large errors in measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

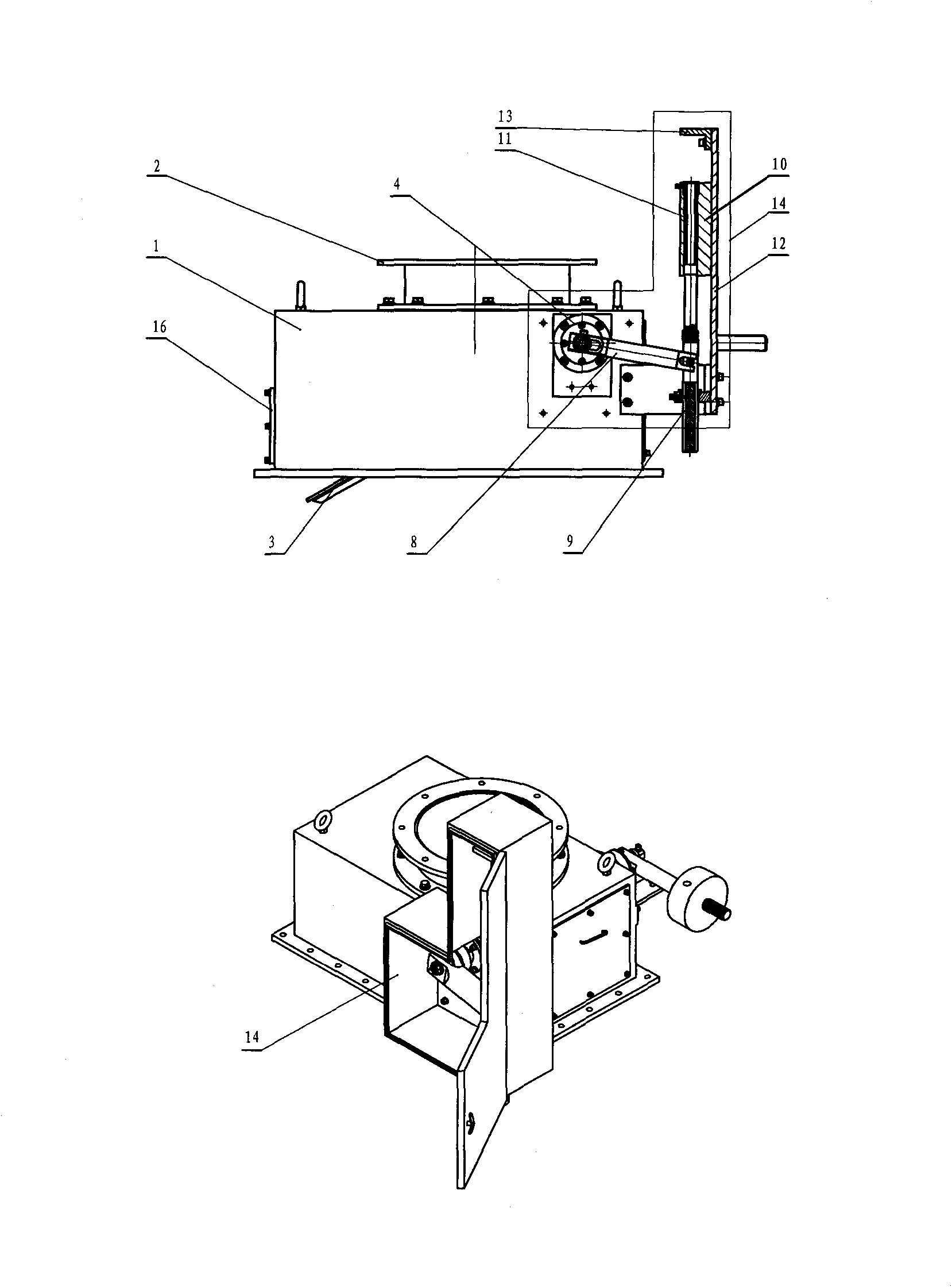

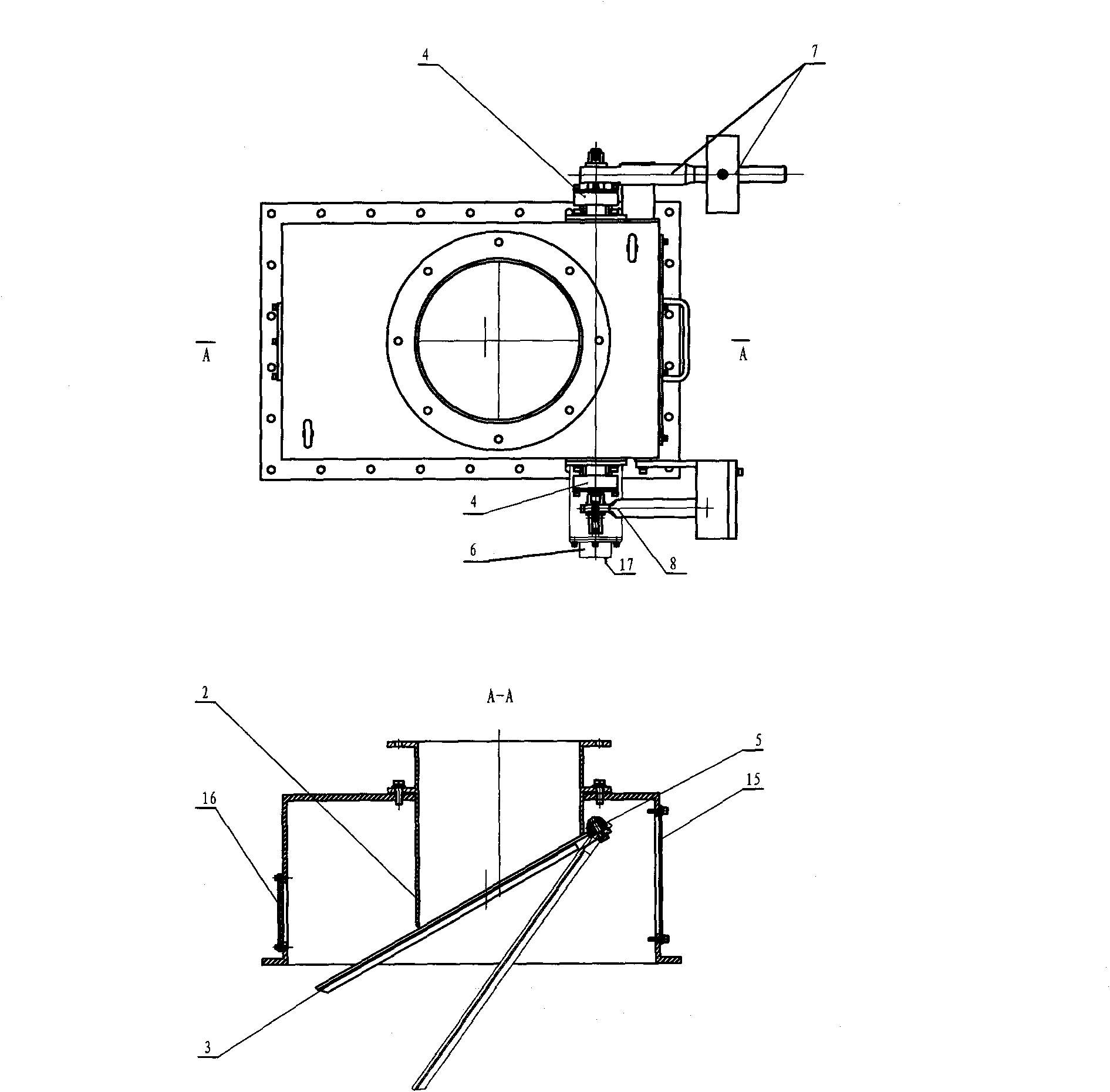

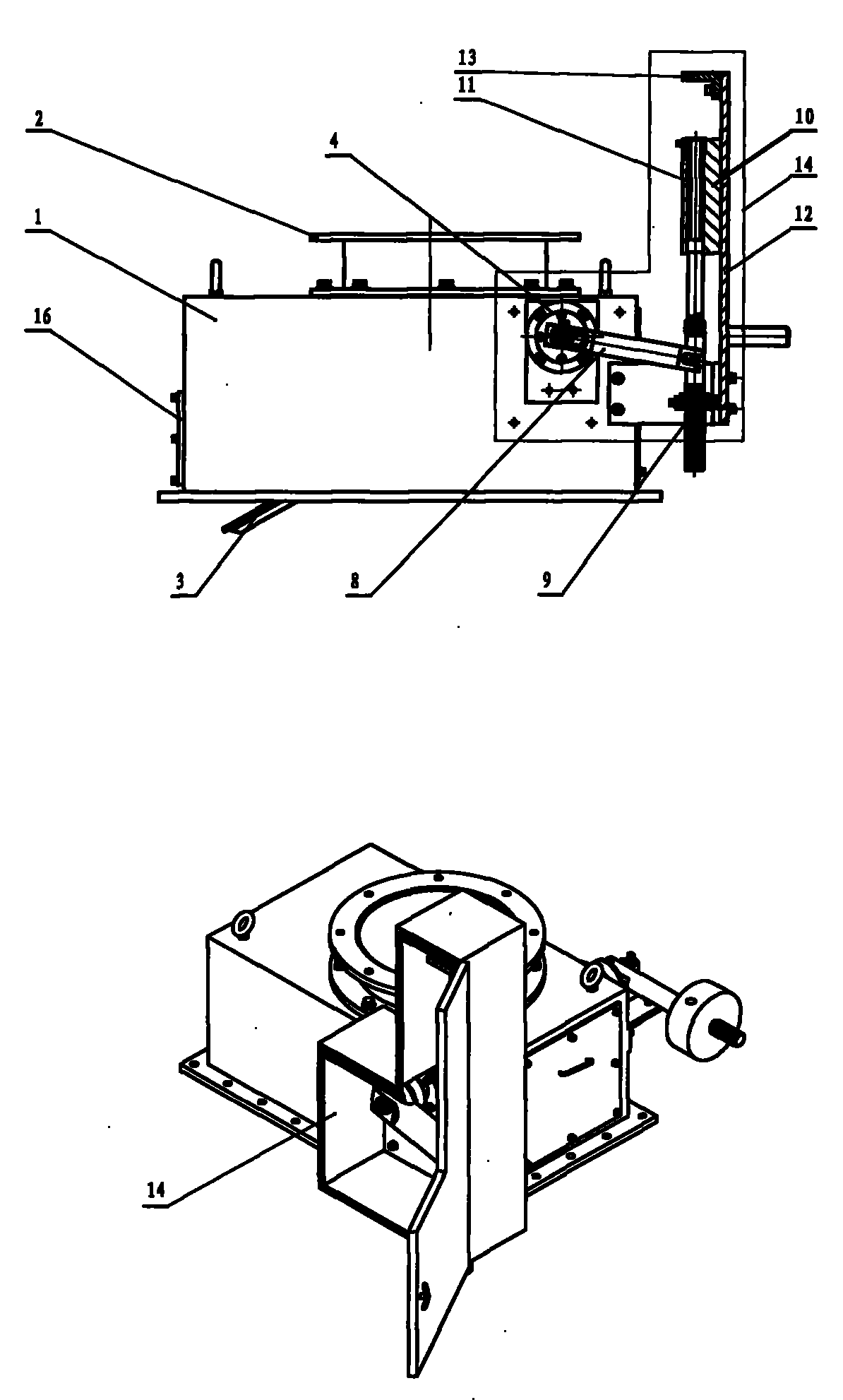

[0008] Instructions attached figure 1 and attached figure 2 Middle: The box (1) of the powder precision measuring device is an airtight container, and the lower end of the feeding tube (2) has a (π / 6) angled oblique opening, which is convenient for powder discharge. The upper end of the dropping tube and the box body The lower ends of the shafts are respectively connected with the conveying pipes, the rotating shaft (5) passes through the box body and is supported by two bearings (4). One end of the rotating shaft is connected to the belt weight lever (7), and the other end is connected to a shaft that can rotate coaxially with the rotating shaft. The angle sensor (6) and the shift fork (8), the shift fork can convert the angle displayed by the angle sensor into the deformation amount of the compression spring (11), the middle section of the rotating shaft is connected with the measuring plate (3), and the measuring plate falls on the sealing Under the action of the powder g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com