Flow monitoring device for air energy heat pump

An air-energy heat pump and flow monitoring technology, which is applied in measuring devices, electromagnetic flowmeters to detect fluid flow, volume/mass flow generated by electromagnetic effects, etc., can solve the problems of unable to monitor and calculate pressure and flow velocity in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

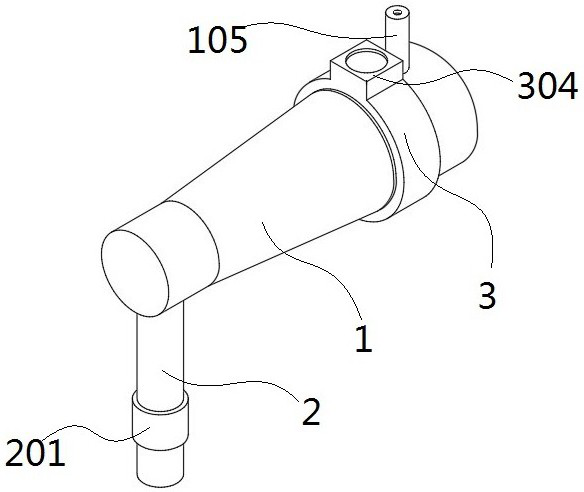

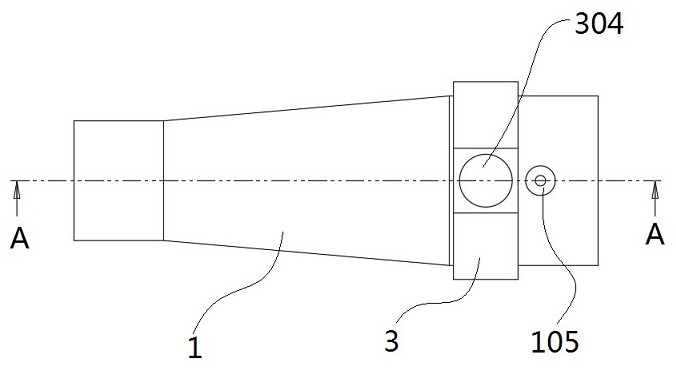

Image

Examples

Embodiment 1

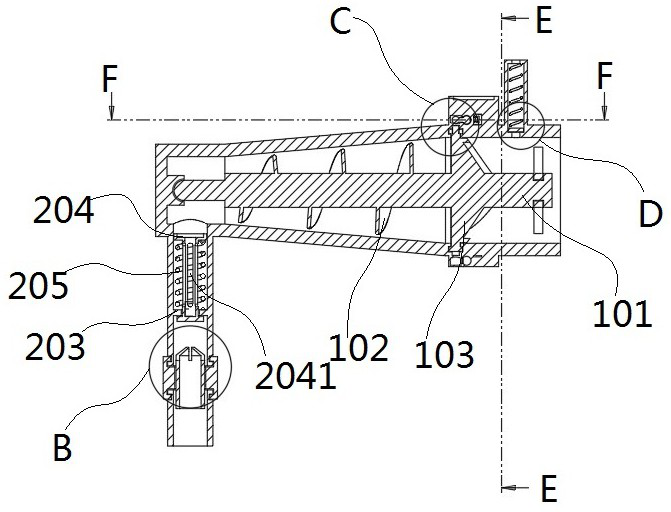

[0034] Embodiment 1: This embodiment is the principle of utilizing the flow monitoring device in the present invention to monitor and measure the pressure in the pipe:

[0035] When the above-mentioned monitoring is required, when the heat pump is stopped, first adjust the pressure regulating sleeve 201 to make the pressure in the pipe the same as the atmospheric pressure, then turn on the heat pump compressor, and the air flow will impact the conveying plate 103 under the pressurized state to make it rotate, and then gradually The level is sent to the pressure regulating pipe 2, and the one-way valve pipe 204 is opened at the same time, and in the case of full communication, the pressure indicating pipe 105 can directly display the current pressure in the pipe.

Embodiment 2

[0036] Embodiment 2: This embodiment is the principle of utilizing the flow monitoring device in the present invention to monitor and calculate the fluid velocity in the pipe:

[0037] When the above-mentioned monitoring is required, the flow rate under the current pressure environment can be obtained by dividing the flow rate in the pipe when the conveying disk 103 rotates once by the time interval by the method of calculating the flow rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com