Track type tensile support

A tension-resistant and bearing technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of limited ability to withstand tension, small allowable horizontal displacement of bearings, insufficient tensile capacity of seismic isolation bearings, etc., to achieve Strong tensile ability, solve the effect of insufficient tensile ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

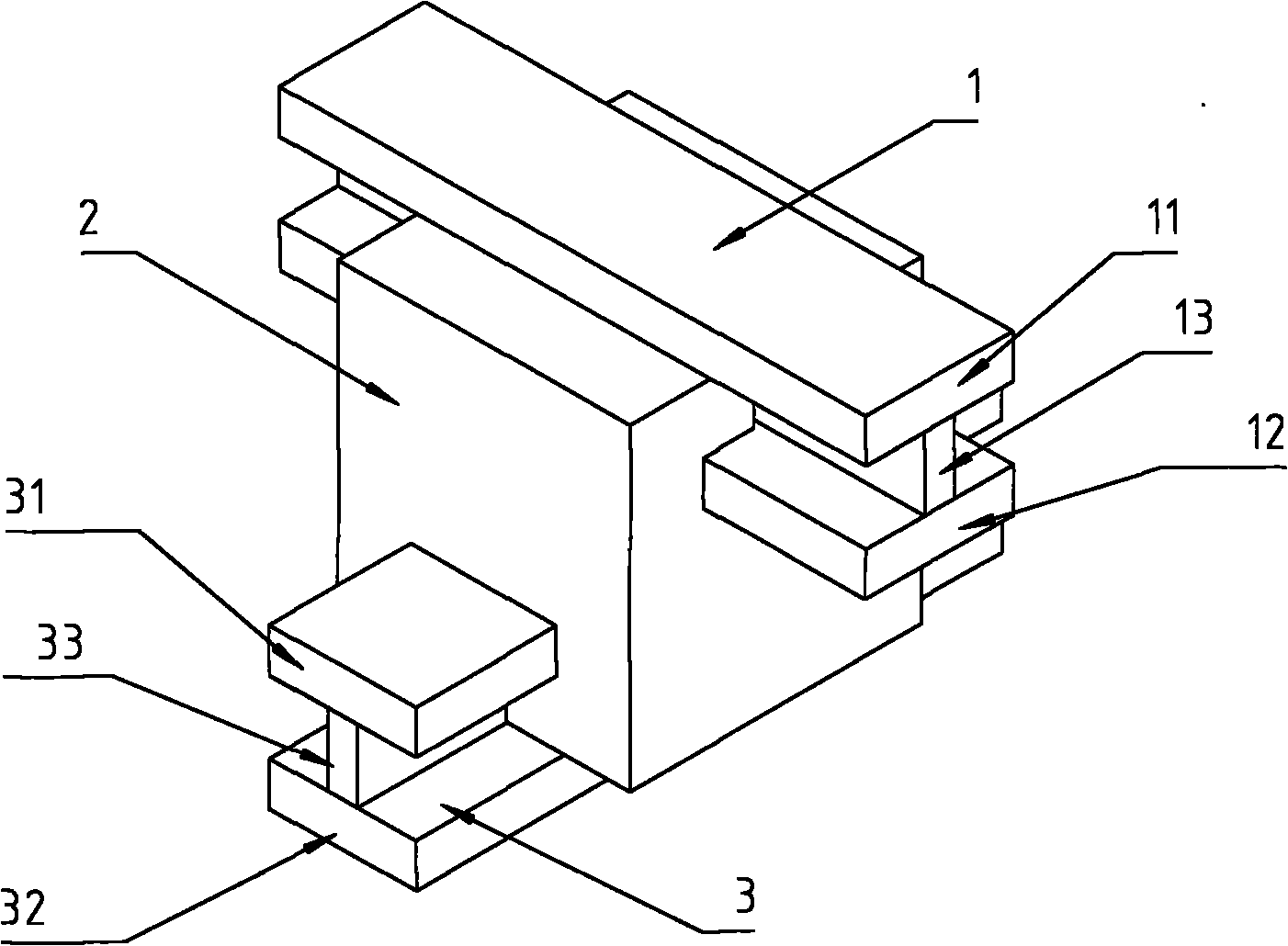

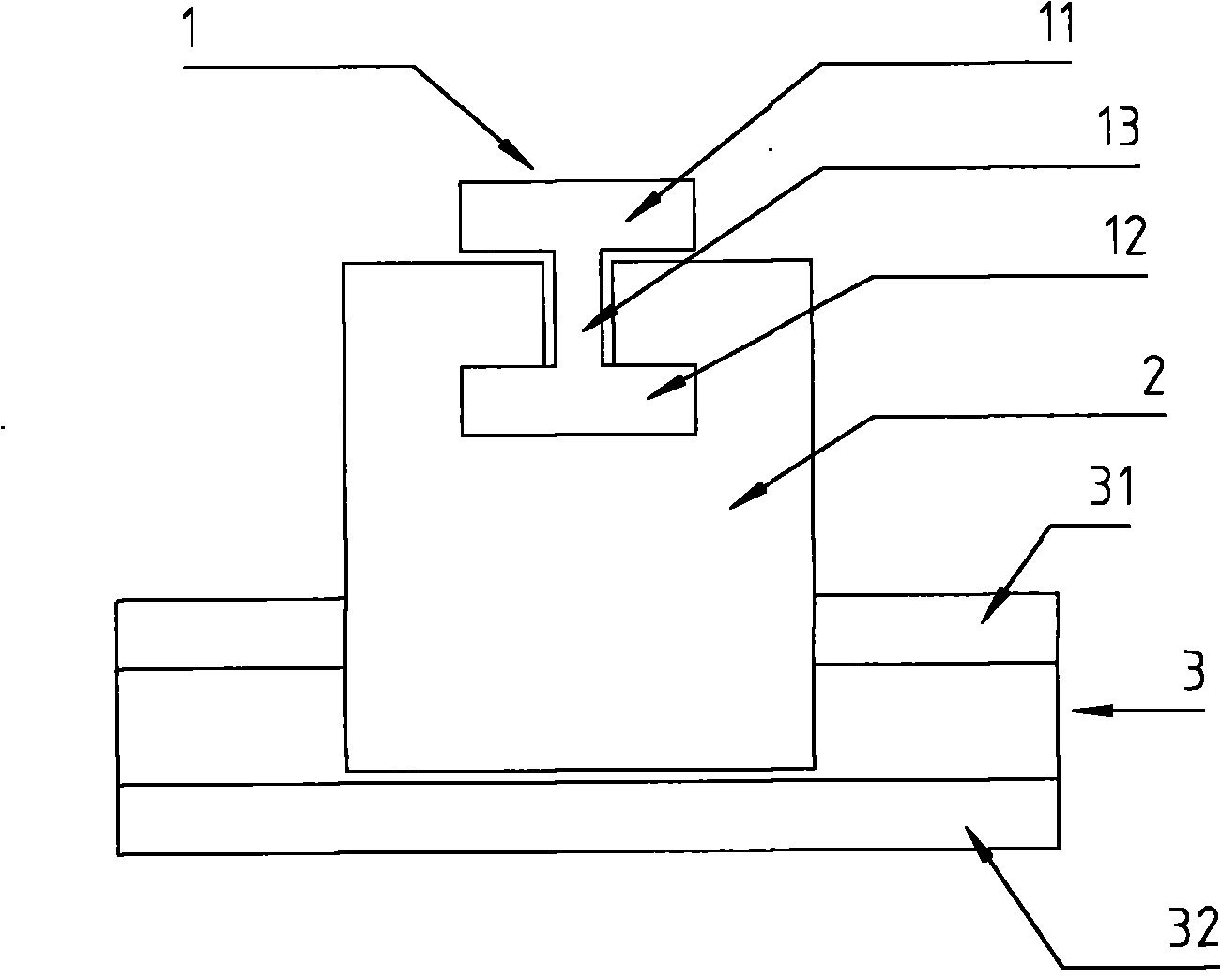

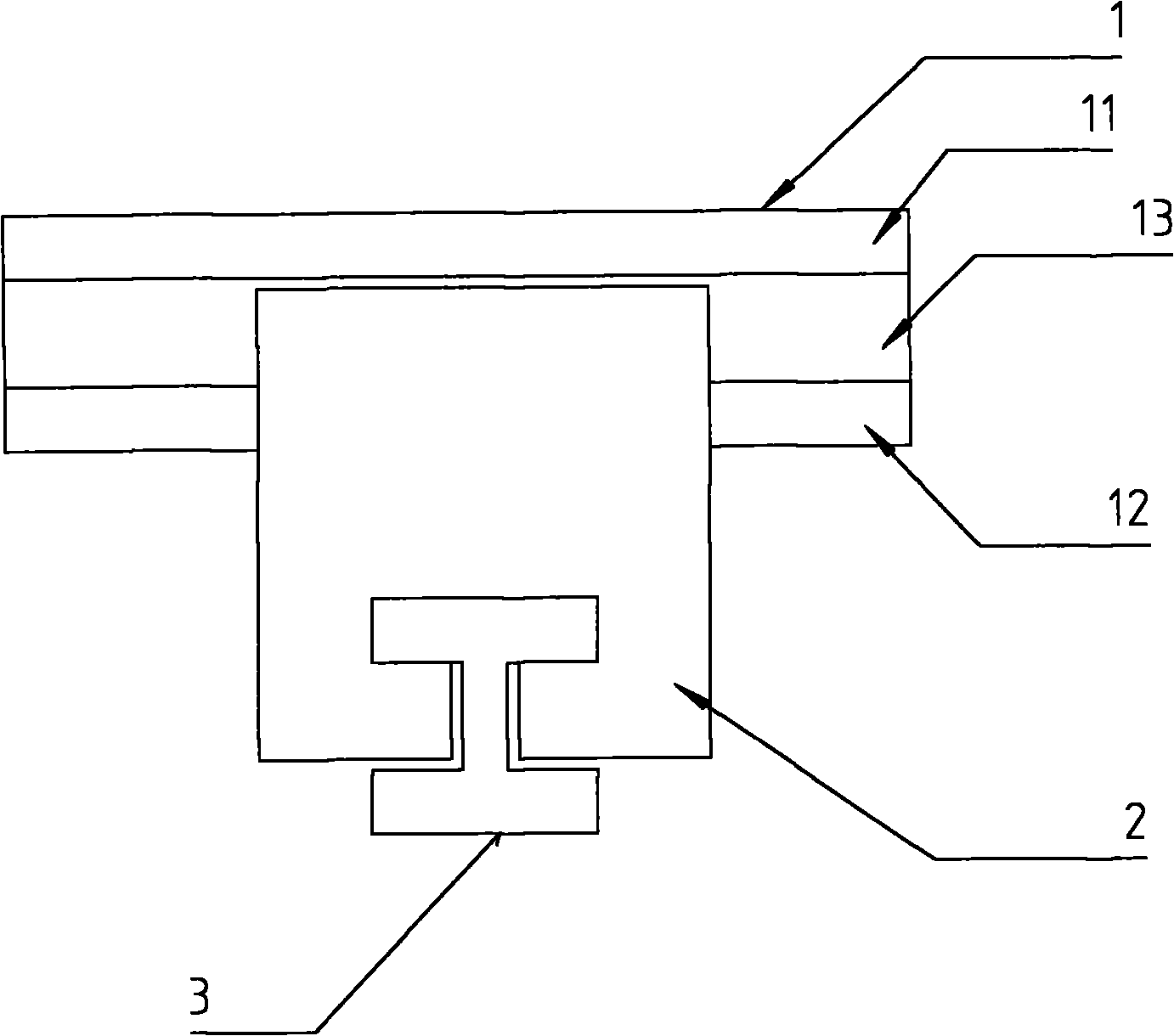

[0033] The above-mentioned structure of the rail-type tensile support in Embodiment 1 realizes large horizontal displacement in the following manner:

[0034] Figure 7 for figure 1 The schematic diagram before the horizontal displacement between the upper and lower track slabs of the rail-type tensile bearing shown in . Such as Figure 7 As shown, in the initial position, the center of the upper track 101 and the center of the lower track 301 coincide. The following track center point 301 is a reference point, established as Figure 7 Orthogonal coordinate system shown. When the relative displacement occurs between the components connected with the rail-type tensile bearing, such as Figure 8 As shown, the upper rail 1 moves in the y direction relative to the slide rail steering block 2, and the slide rail steering block 2 moves in the x direction relative to the reference point 301, so that the upper rail 1 has an x-direction and a y-direction motion relative to the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com