Wall thickness calipers for drum brake and hub

A brake drum and wheel hub technology, applied in the field of calipers, can solve the problems affecting the quality of the production process, inaccurate wall thickness measurement, etc., and achieve the effects of ensuring the quality of the production process, improving the wall thickness measurement accuracy, and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

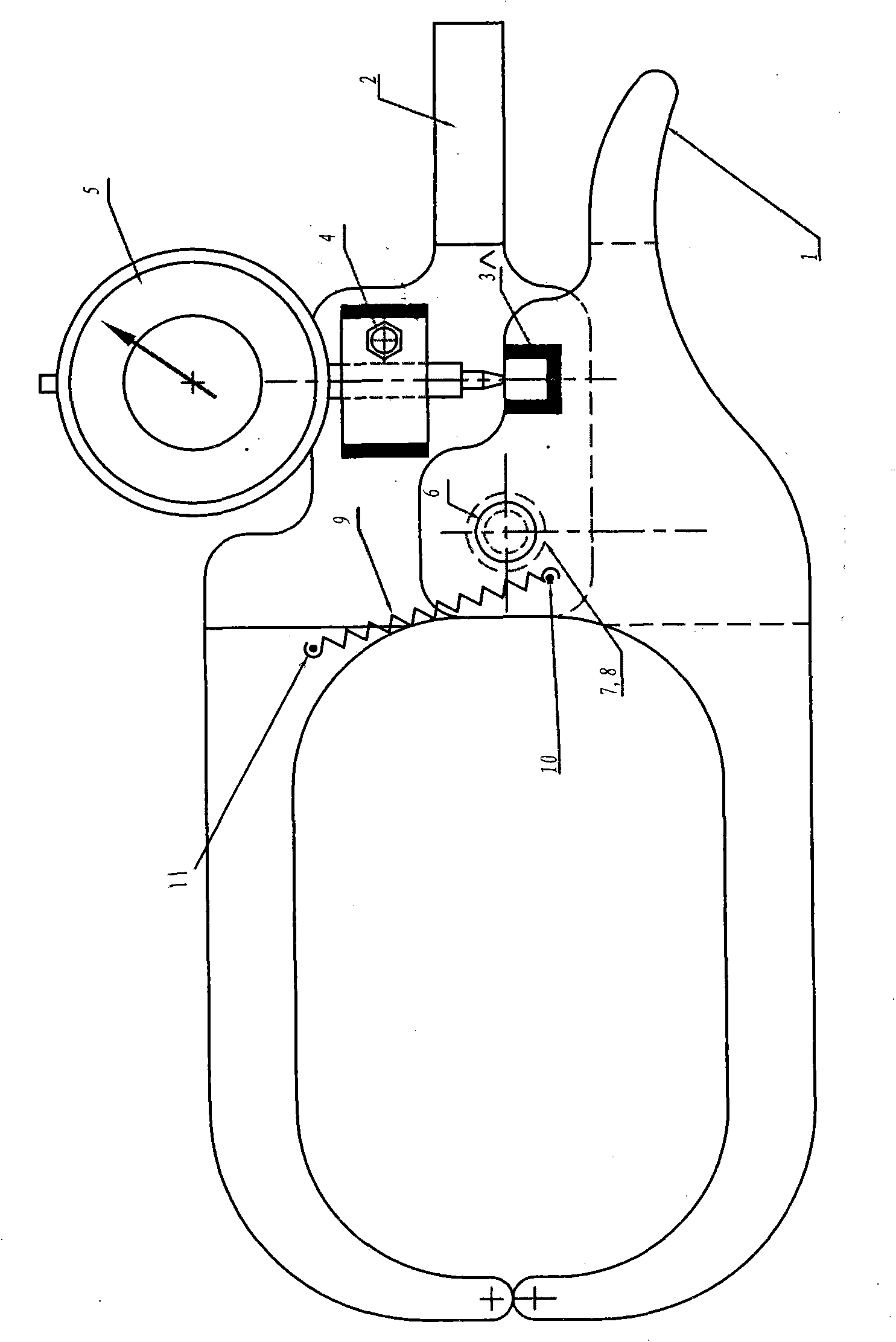

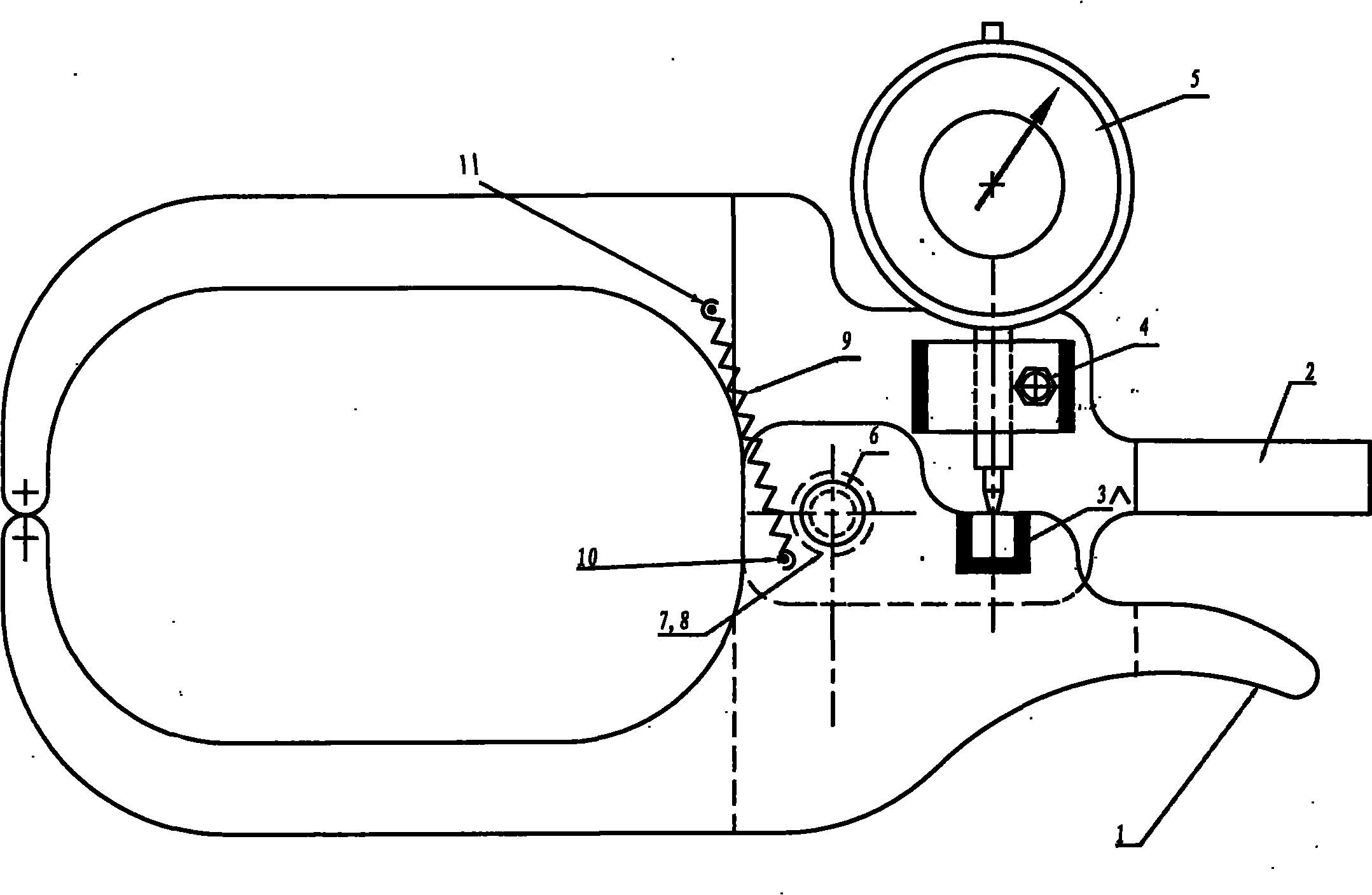

[0008] A wall thickness caliper for a brake drum and a wheel hub, comprising a lower caliper body 1, an upper caliper body 2 and a main shaft 6, the main shaft 6 connects the lower caliper body 1 and the upper caliper body 2 together to form a caliper, on the left side of the main shaft 6 On the lower caliper body 1 of side, be fixedly provided with pull-down spring fastening nail 10, on the upper pliers body 2 of the left side of main shaft 6, be fixedly provided with upper tension spring fastening nail 11, on upper tension spring fastening nail 11 and pull-down A spring 9 is arranged between the spring fastening nails 10. When the handles of the upper and lower caliper bodies at the tail end of the caliper are pinched hard, the jaws of the caliper will be opened, and the spring 9 will be stretched, and the side workpiece will be stuck into the tensioned hole. Between the two pincer heads that are opened, the spring 9 produces a pull-back force to the head of the caliper and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com