Bottle-conveying transition device in bottle blowing machine

A bottle blowing machine and bottle feeding technology, which is applied to hollow objects, other household appliances, household appliances, etc., can solve the problems of prolonged production cycle, complicated structure, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

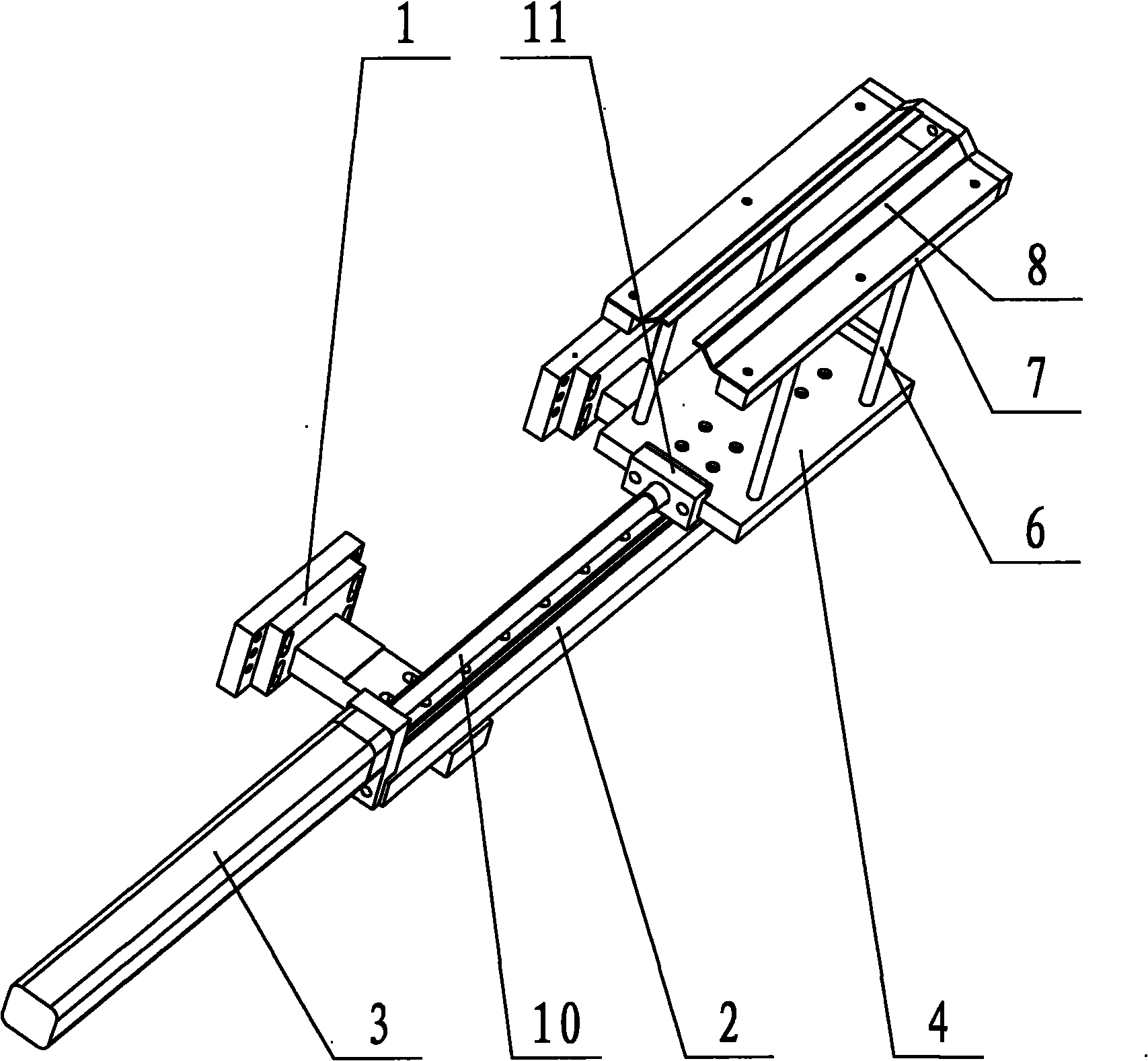

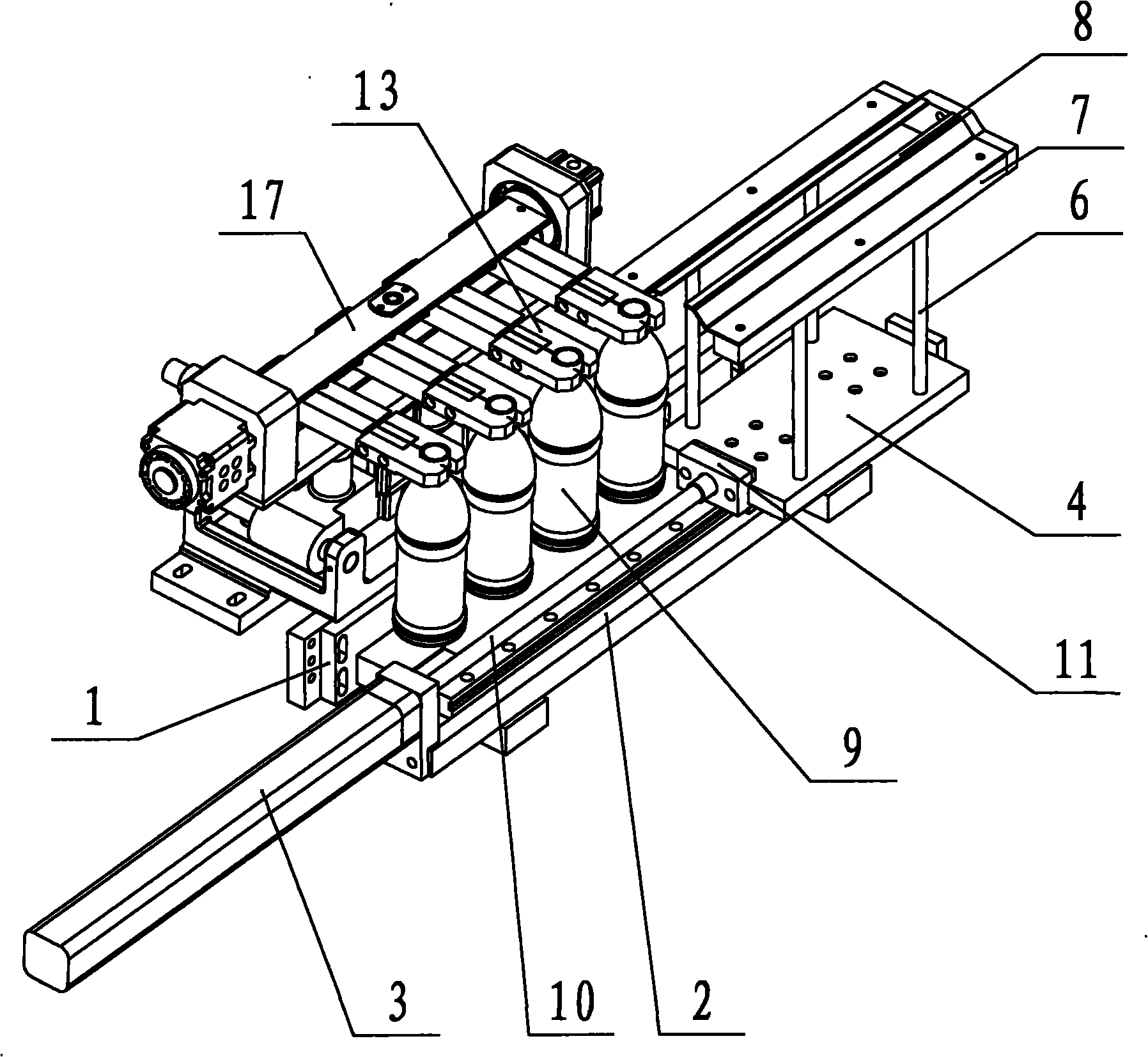

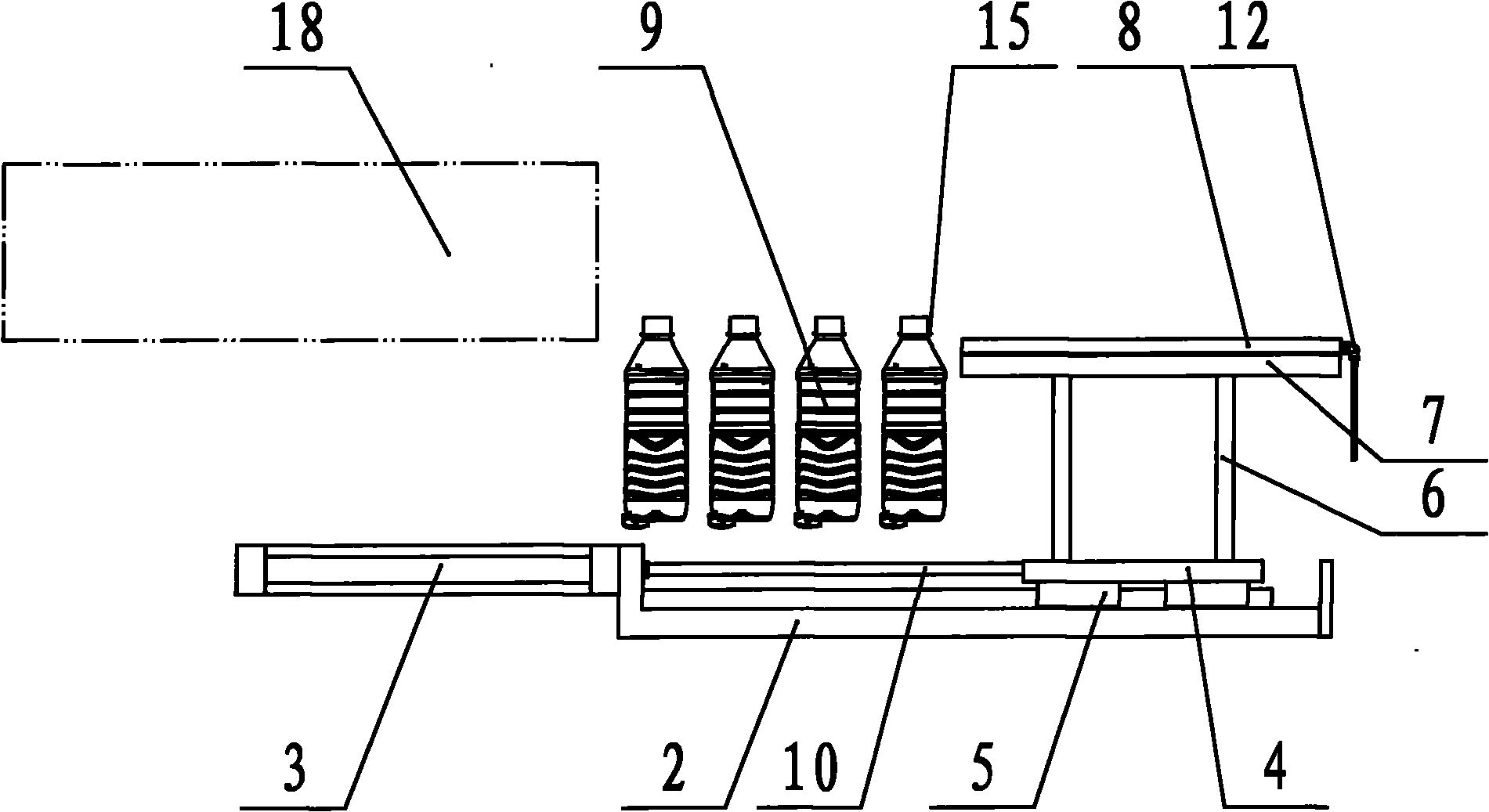

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] like Figure 9 As shown, the bottle feeding transition device in the bottle blowing machine of the present invention includes: an inserting plate 19 fixedly connected with the upper turning arm 17 of the bottle discharging manipulator in the blowing molding machine, and the inserting plate 19 is provided with a U-shaped bottle hanging groove 20. The inner surface of the bottle hanging groove 20 is provided with a groove 16 that matches the support ring 15 on the bottle 9 . For the convenience of connection between the present invention and the bottle-discharging manipulator, a fixed seat 21 that cooperates with the turning arm 17 on the bottle-discharging manipulator is provided on one side of the inserting plate 19 .

[0019] The working principle of the present invention is: the present invention is fixed on the turning arm 17 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com