New compression valve assembly

A compression valve and assembly technology, applied in the direction of springs, shock absorbers, spring/shock absorbers, etc., can solve the problem of loss of shock absorption effect of the shock absorber, plastic deformation of the compression valve plate, permanent failure of the compression valve assembly, etc. problems, to achieve the effect of improving the ability to resist accidental impact deformation, improving service life and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

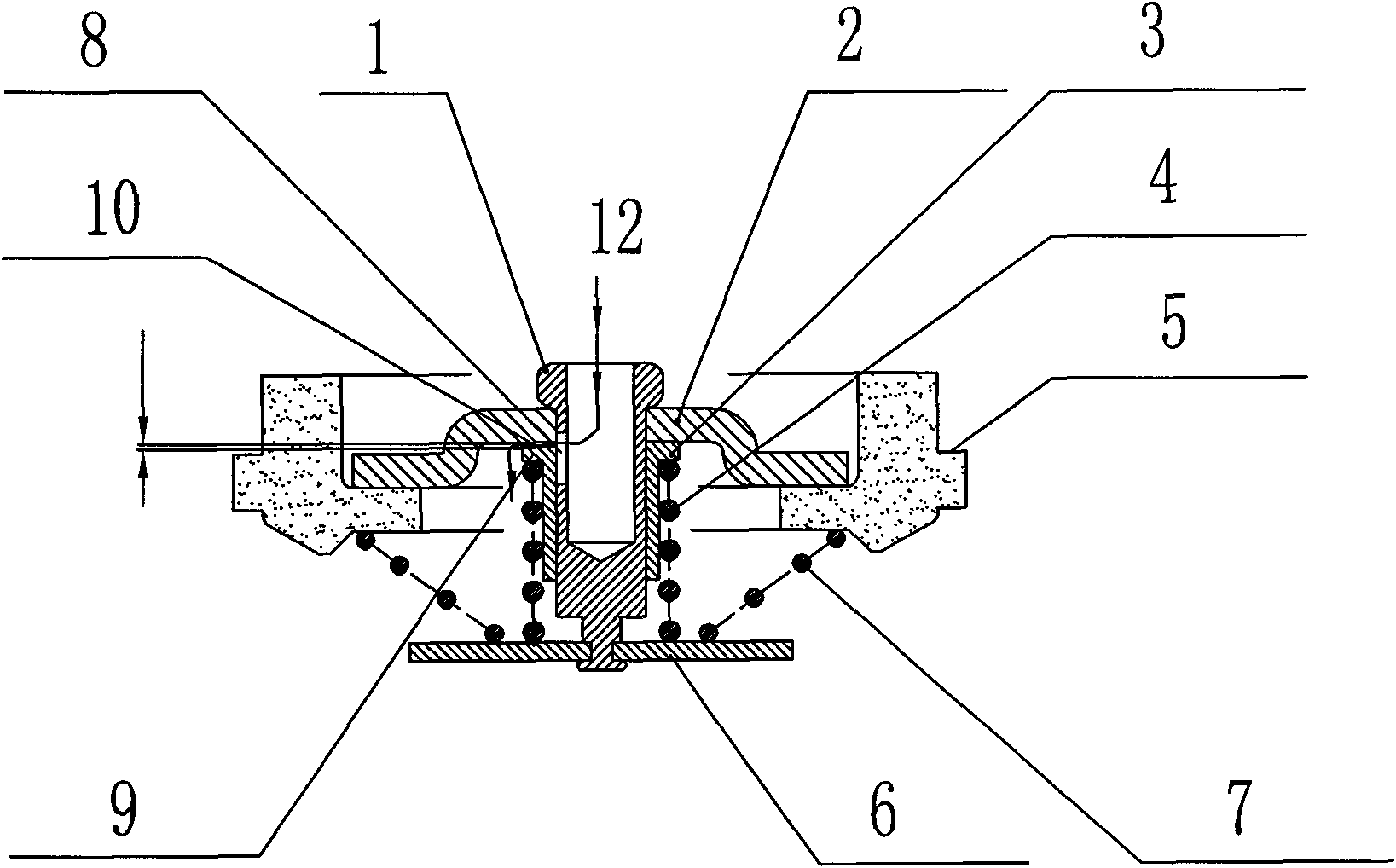

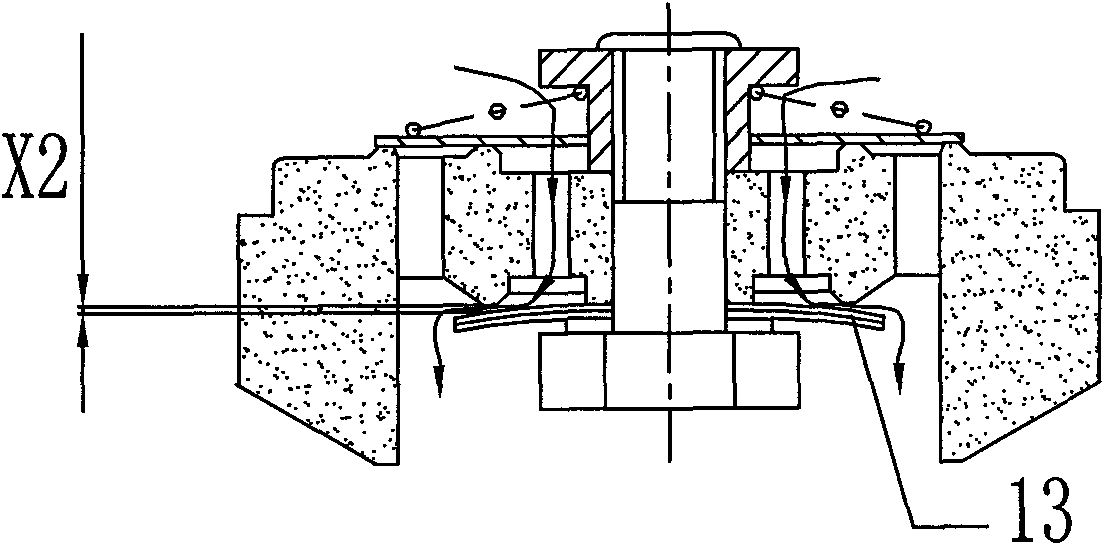

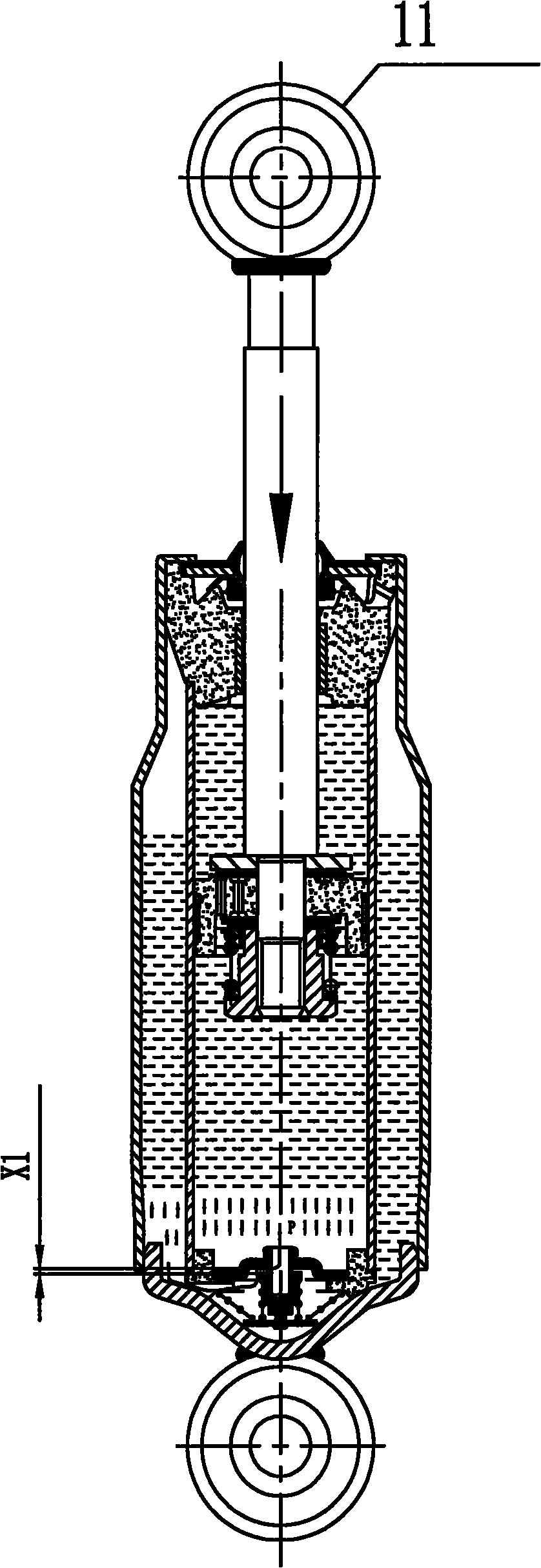

[0014] Example: such as figure 1 , this new type of compression valve assembly has a compression valve seat 5 on the outside, a valve core 1 inside, and the outer side of the limit ring 2 sleeved on the valve core 1 is fixed on the compression valve seat 5, and the valve core 1 is covered with a A sliding fit compression valve body 3 is formed, the upper part of the compression valve body 3 extends to form a valve body base 9, the bottom of the valve core 1 is equipped with a limit plate 6, one end of the compression spring 4 is fixed on the valve body base 9, and the other end is fixed on the valve body base 9. On the limiting piece 6 , under the action of the compression spring 4 , the compression valve body 3 is offset against the limiting ring 2 through the valve body base 9 . When the compression valve body 3 moves relative to the valve core 1, a compression orifice 10 is formed between the valve body base 9 and the limit ring 2, the inside of the valve core 1 is hollow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com