Positioning mould holder of microscope

A technology for microscopes and mold bases, applied in microscopes, optics, instruments, etc., can solve problems such as low production efficiency, unstable product quality, and difficulty in the smoothness of wire drawing die holes, and achieve the effect of improving observation efficiency and quality

Inactive Publication Date: 2010-12-08

铜陵市精品工具模具有限责任公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to solve the problems that it is difficult to observe the smoothness of the wire drawing die hole with a microscope, which leads to low production efficiency and unstable product quality.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

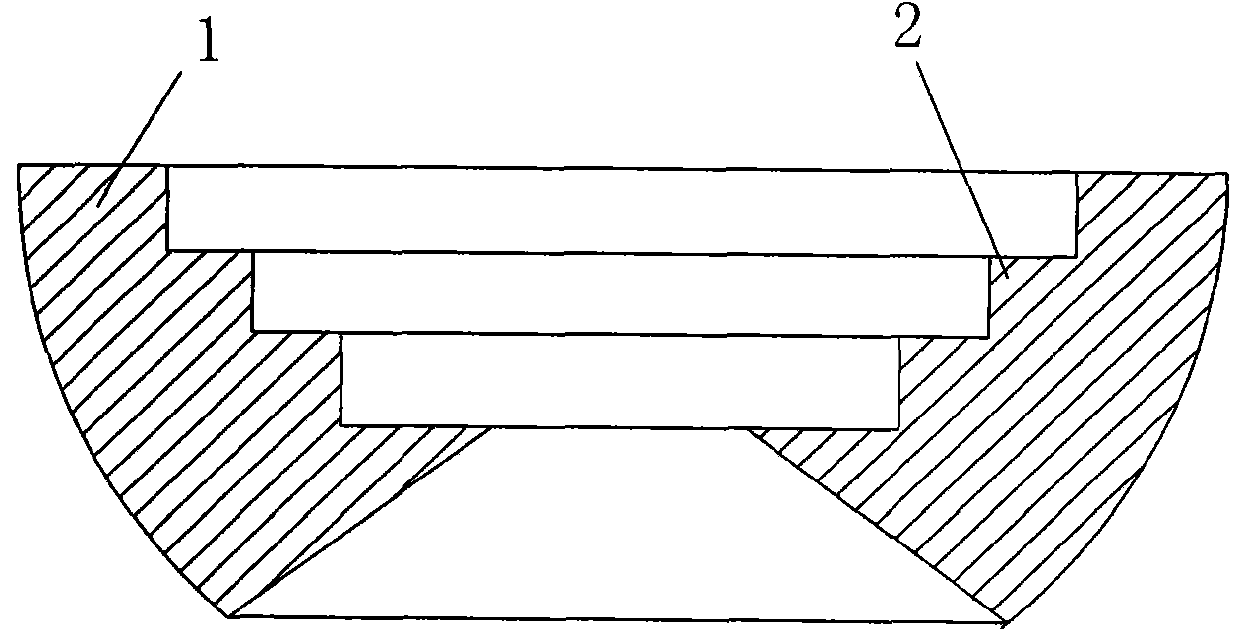

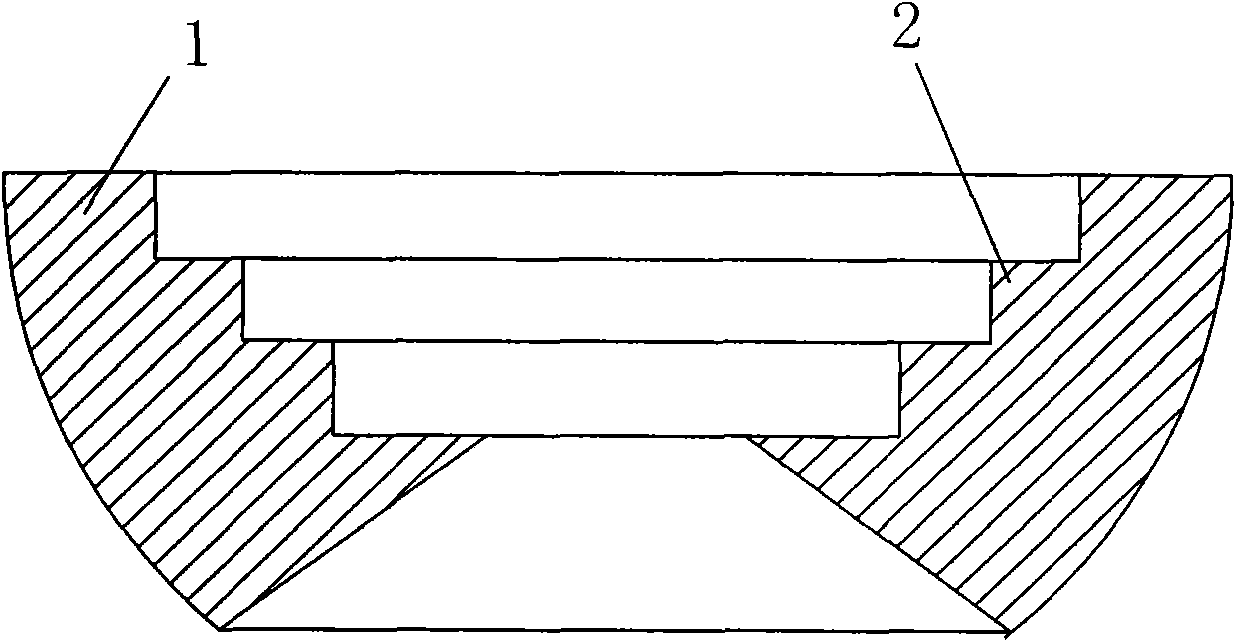

[0008] Such as figure 1 As shown, the microscope positioning mold base is composed of a spherical segment 1, and the center of the spherical segment 1 is provided with a cavity, and several coaxial annular stepped grooves 2 for placing different molds are provided in the cavity.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a positioning mould holder of a microscope consisting of a segment (1). The centre of the segment (1) is provided with a hollow cavity, and the hollow cavity is provided with a plurality of coaxial annular stepped grooves (2) for containing different moulds. The invention can observe a wire-drawing mould from all angles, thereby the observation is not labor-consuming and time-consuming, the observation efficiency is greatly improved, and the quality of the product is improved.

Description

technical field [0001] The invention relates to a stage for placing workpieces of a microscope. Background technique [0002] In the production of wire drawing dies, the processed wire drawing dies need to be observed under a microscope for the smoothness of the wire drawing die hole. There is a through hole reserved on the workpiece placing table of the microscope, and the customer can set the workpiece table according to the needs. At present, when producing wire drawing dies to observe the smoothness of the holes through a microscope, the worker holds the wire drawing die in one hand and adjusts the focus with the other hand for observation. Because it is very difficult to change the angle of the drawing die with one hand, it is also very difficult to observe the smoothness of the drawing die, so the production efficiency is low and the product quality is unstable. Contents of the invention [0003] The purpose of the invention is to solve the problems that it is diff...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02B21/24

Inventor 陈光宝程路平

Owner 铜陵市精品工具模具有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com