Porous polymeric resins

A technology of porous polymers and resins, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve problems such as impure products and low capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0198] These examples are for illustrative purposes only and are not intended to limit the scope of the appended claims. Solvents and other reagents used were obtained from Sigma-Aldrich Chemical Company (Milwaukee, WI) unless otherwise noted.

[0199] testing method

[0200] Cation Exchange Capacity of Immunoglobulin G (IgG)

[0201] A 50% by volume slurry of cation-exchange polymer beads was prepared by mixing the polymer beads with deionized water, centrifuging at 3000 relative centrifugal force (rcf) for 20 min to form a bead-packed bead bed, and then conditioning for deionization Amount of water such that the total volume is twice the packed bead bed. The slurry was mixed well to suspend the polymer beads, then a 400 microliter sample of the slurry was pipetted into a 0.45 micron pore size 5 mL cellulose acetate centrifugal microfilter available from VWR (Eagan, MN) was obtained commercially. Water was removed by centrifugation at 3000 rcf for 5 minutes. The poly...

example 1

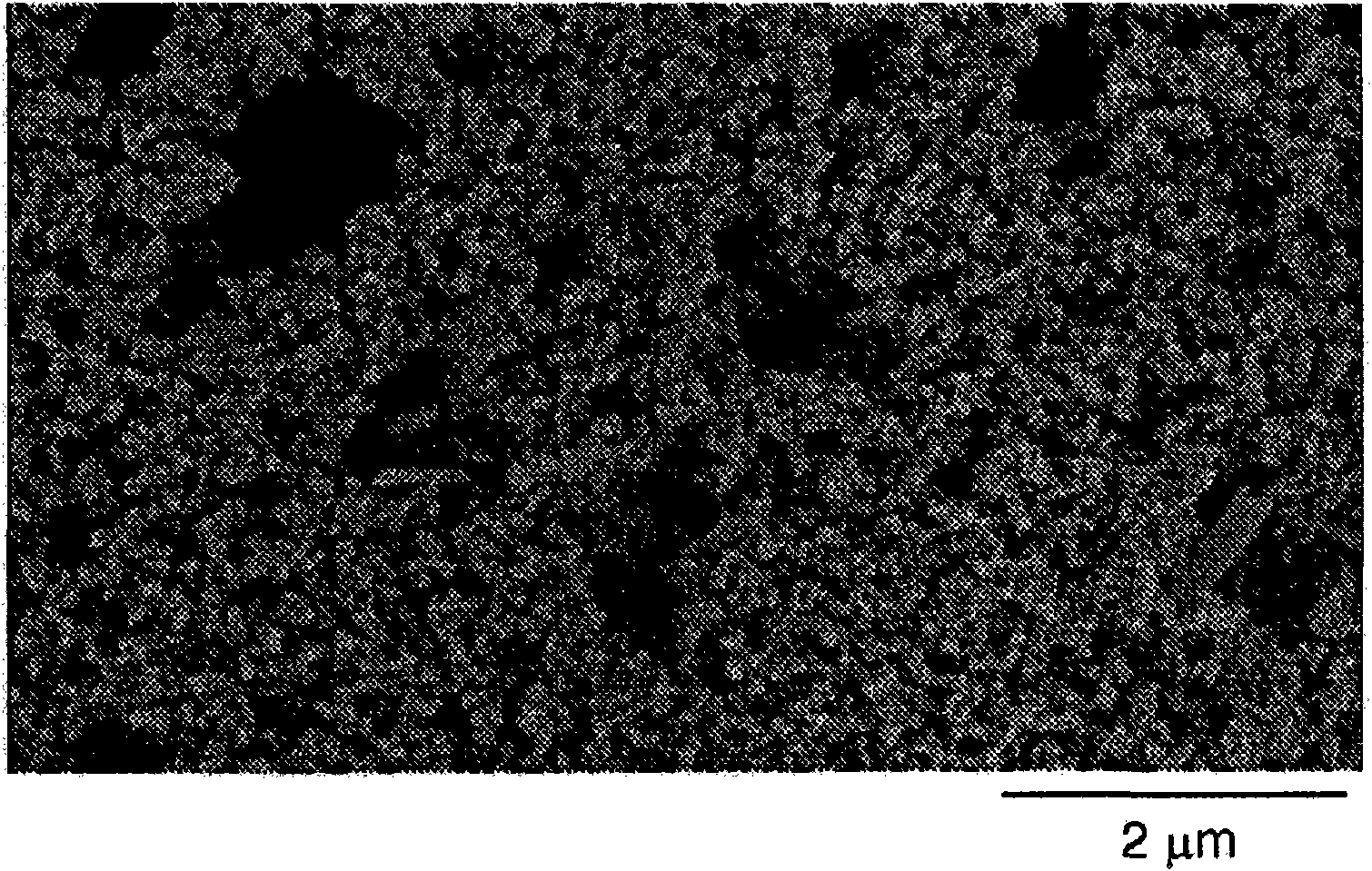

[0211] Polymeric beads were prepared by reverse phase suspension polymerization using a monomer mixture comprising AMPS and MBA in a weight ratio of 35:65. Add PETROLITE D110 as organic aggregates to the aqueous phase.

[0212] More specifically, the organic phase was prepared by adding Suspending Agent 1 (0.56 g) and heptane (536 mL) into a flask equipped with a mechanical stirrer (stirring speed of 450 rpm), nitrogen inlet, thermometer, belt temperature Controller heating jacket and condenser. The organic phase in the flask was heated to 35° C. with stirring and sparged with nitrogen for 15 minutes.

[0213] Prepare the aqueous phase by combining: MBA (18.2 g), AMPS (19.6 g 50 wt% aqueous solution), IPA (85 mL), PETROLITE D110 (5 mL), deionized water (27.2 mL), PEG 6000 (10 g 50 wt % aqueous solution) and ethylene glycol (20 mL). The aqueous phase is stirred and heated at a temperature in the range of 30 to 35°C to dissolve the MBA. Stir again and add sodium persulfate (...

example 2-5

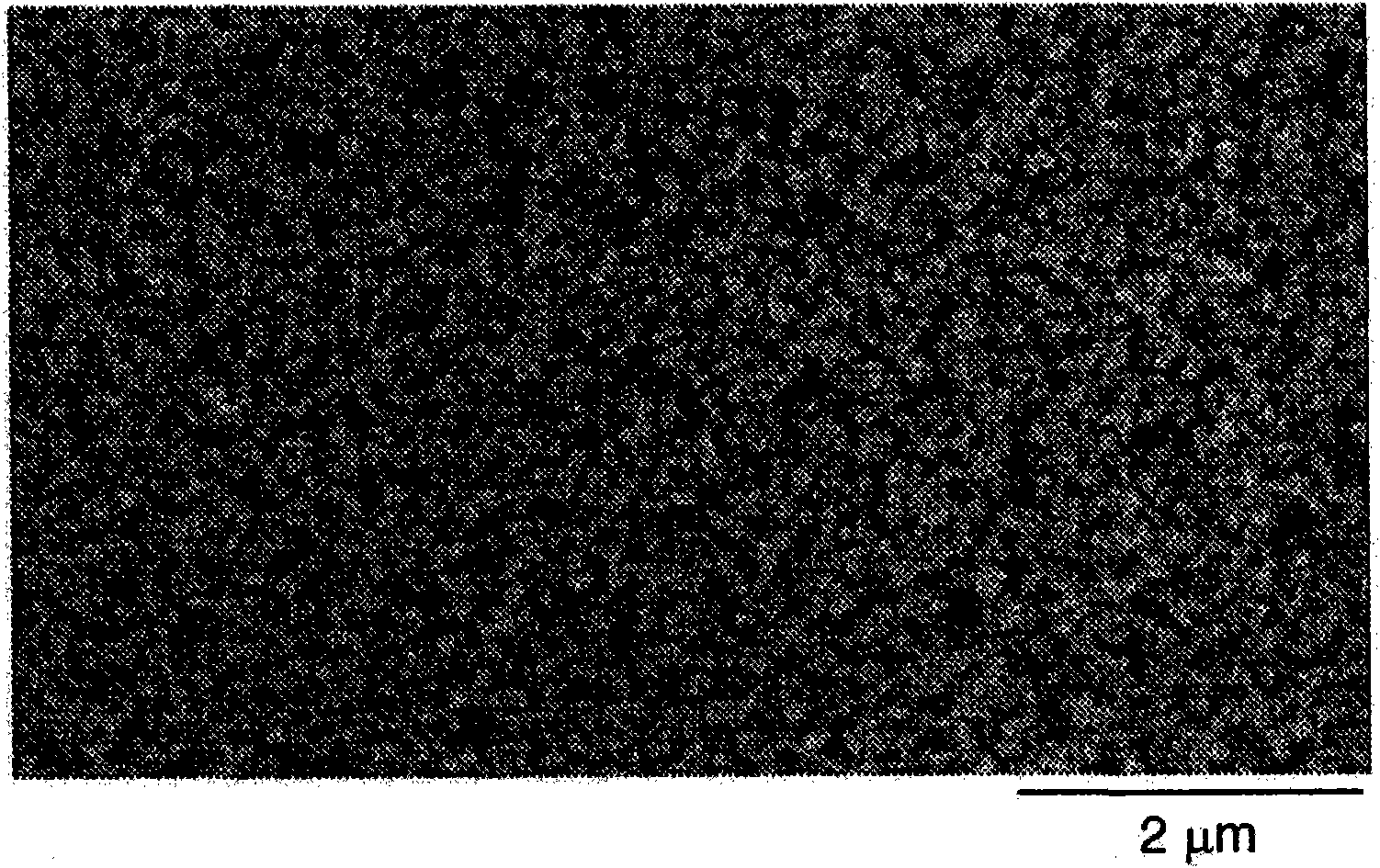

[0223] Polymeric beads were prepared by reverse phase suspension polymerization using a monomer mixture comprising AMPS and MBA in a weight ratio of 35:65. Various aqueous dispersions of organic aggregates were added to the aqueous phase. Example 2 contained UNITHOX D-100. Example 3 contained UNITHOX D-300. Example 4 contained PETROLITE D-800. Example 5 contained PETROLITE D-900.

[0224] More specifically, the organic phase was prepared by adding Suspending Agent 1 (0.56 g) and heptane (536 mL) into a flask equipped with a mechanical stirrer (stirring speed of 450 rpm), nitrogen inlet, thermometer, belt temperature Controller heating jacket and condenser. The organic phase in the flask was heated to 35° C. with stirring and sparged with nitrogen for 15 minutes.

[0225] An aqueous phase was prepared containing the following: MBA (18.2 g), AMPS (19.6 g of a 50 wt. ), PEG 6000 (10 grams of a 50% by weight aqueous solution) and ethylene glycol (20 mL). The aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com