Integrated error measuring technology and method thereof of gear pair

A technology of overall error and gear pair, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as difficult error traceability, failure to adopt, transmission error, etc., and achieve the effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

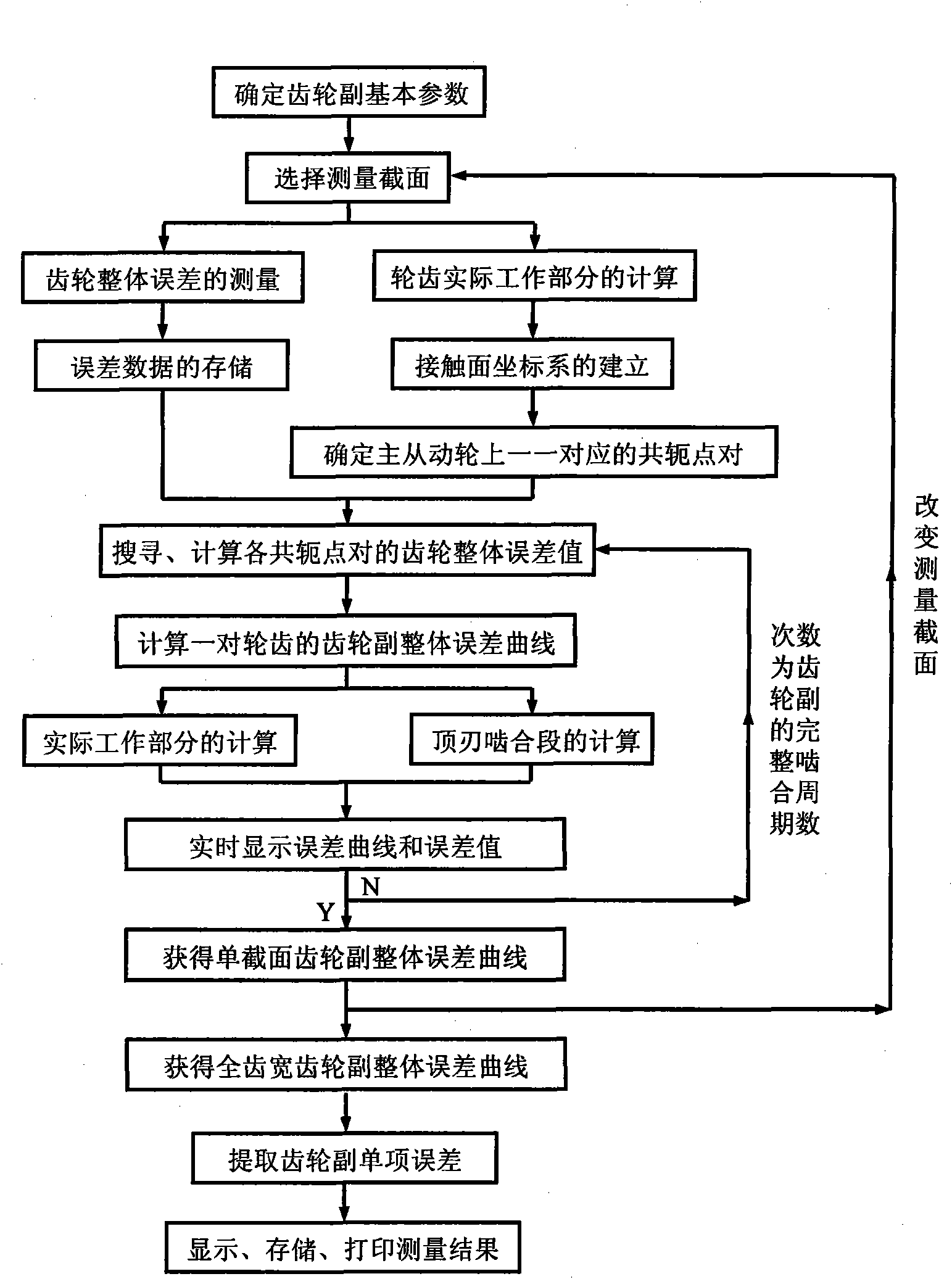

[0070] Below in conjunction with accompanying drawing, the present invention will be further described:

[0071] This implementation realizes the indirect measurement method of the overall error of the gear pair on the basis of the hardware of the gear overall error measuring instrument CZ450.

[0072] 1. The hardware foundation and overall architecture of the measurement system

[0073] The overall architecture of this embodiment is as follows Figure 6 As shown, there are three modules: error data acquisition module, gear overall error measurement and storage module, and gear pair overall error calculation and storage module.

[0074] Among them, the error data acquisition module is the basis and front-end link of the measurement system, and is the only link that directly accesses the hardware of the measurement system. This implementation is based on the hardware structure of the gear overall error measuring instrument CZ450, and the standard measuring worm The produced j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com