Steel tube end part inductive heating device with temperature detection system

An induction heating device and detection system technology, applied in the field of seamless steel pipe processing, can solve problems such as difficult temperature detection, and achieve the effects of broad application prospects, stable quality of steel pipe thickening, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

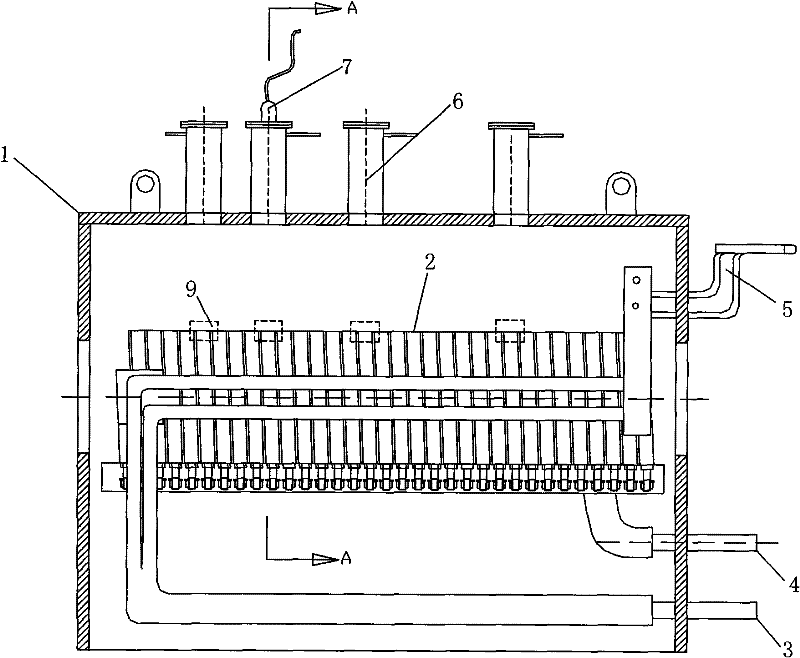

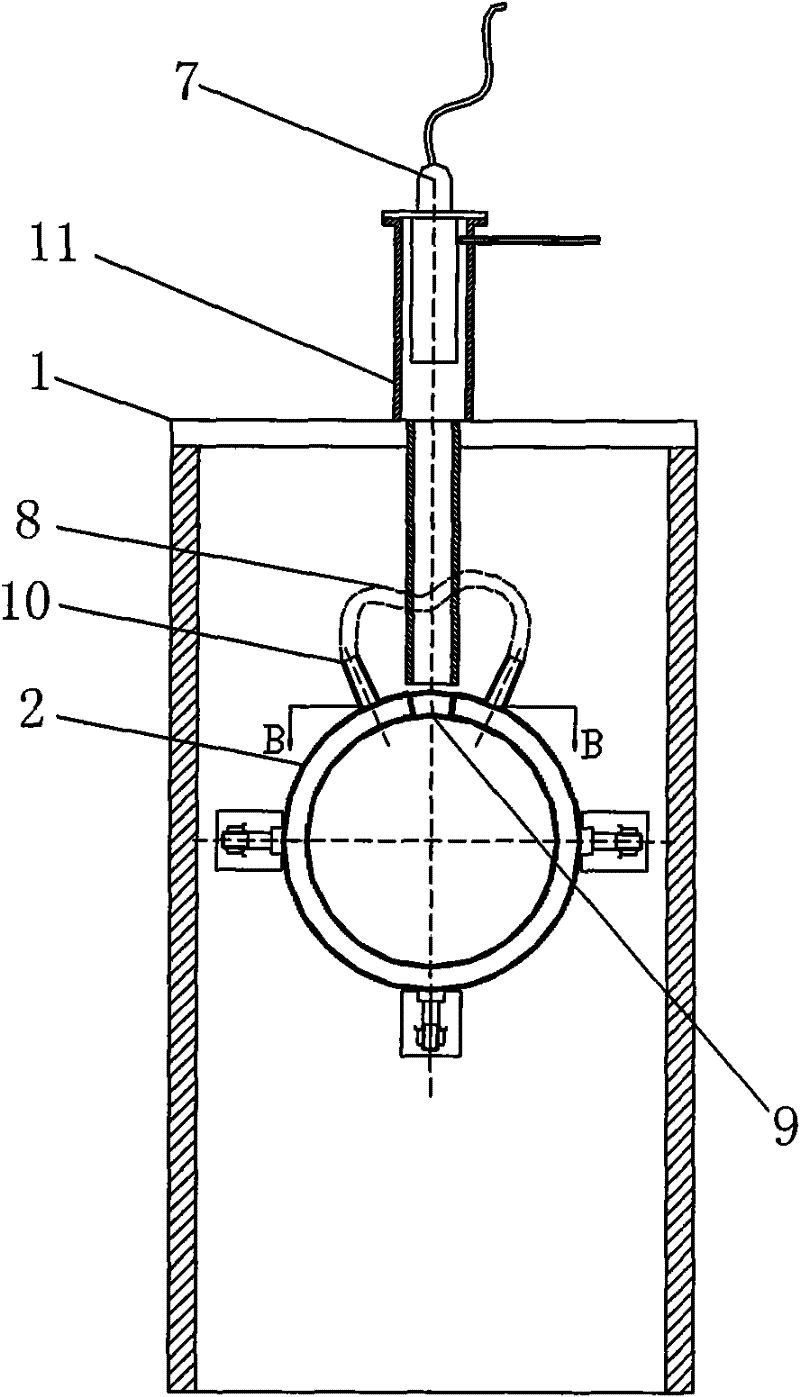

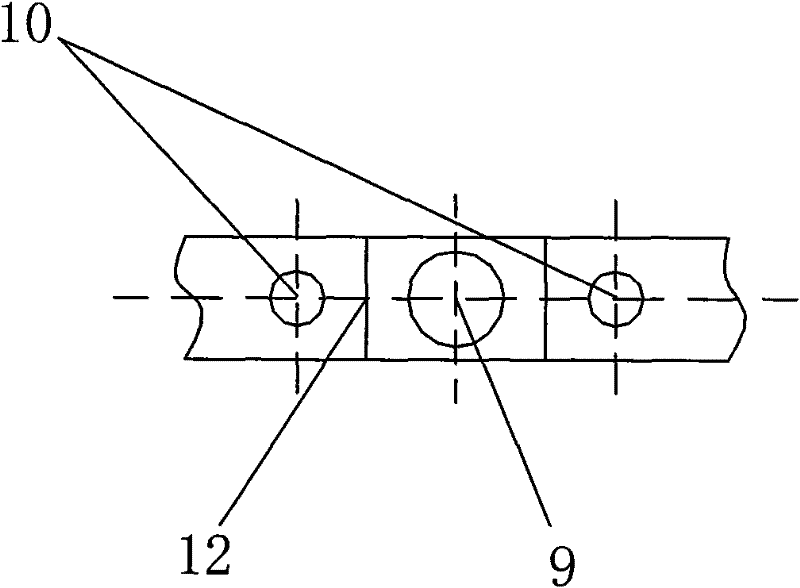

[0021] Such as figure 1 , 2 , 3, a steel pipe end induction heating device with a temperature detection system, including a box body 1, an induction coil 2, a coil water inlet pipe 3, a coil water outlet pipe 4, an induction coil connecting busbar 5 and an infrared optical fiber temperature measuring probe 7. The box body 1 is sequentially opened with four hole-type temperature measuring probe fixing ports 6, and the opening positions are determined according to the penetration depth of each pass of the steel pipe, and the induction coil 2 is opened with a temperature measuring The position of the hole 9 and the temperature measurement hole 9 correspond to the fixed port 6 of the temperature measurement probe. The two ends of the temperature measurement hole 9 are equipped with a cooling water nozzle lead-out head 10 and a coil connection baffle 12. The coil connection baffle 12 ensures that the induction coil 2 The conduction of the two cooling water nozzles and the entry of...

Embodiment 2

[0023] Such as Figure 4 , 5 , 6, a steel pipe end induction heating device with a temperature detection system, including a box body 1, an induction coil 2, a coil water inlet pipe 3, a coil water outlet pipe 4, an induction coil connecting busbar 5 and an infrared optical fiber temperature measuring probe 7. The box body 1 is provided with a temperature measuring probe fixing port 6, and the temperature measuring probe fixing port 6 includes a chute 13, a flange 14 is installed in the chute 13, and an external thread sleeve is installed on the flange 14 Pipe 16, the externally threaded sleeve 16 is covered with a fastening nut 15; when detecting, the externally threaded sleeve 16 slides to the corresponding position along the chute 13 under the guidance of the flange 14, and the externally threaded sleeve 15 is rotated to tighten the externally threaded sleeve. The pipe 16 is fixed at a certain position, and the temperature measuring probe 7 passes through the externally th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com