Mid-span closure method for steel box girder of cable stayed bridge

A technology for steel box girders and cable-stayed bridges, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high risk, dense circumferential welds, and complicated operations, and achieve simple and convenient construction procedures, which are beneficial The effect of structural stress and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

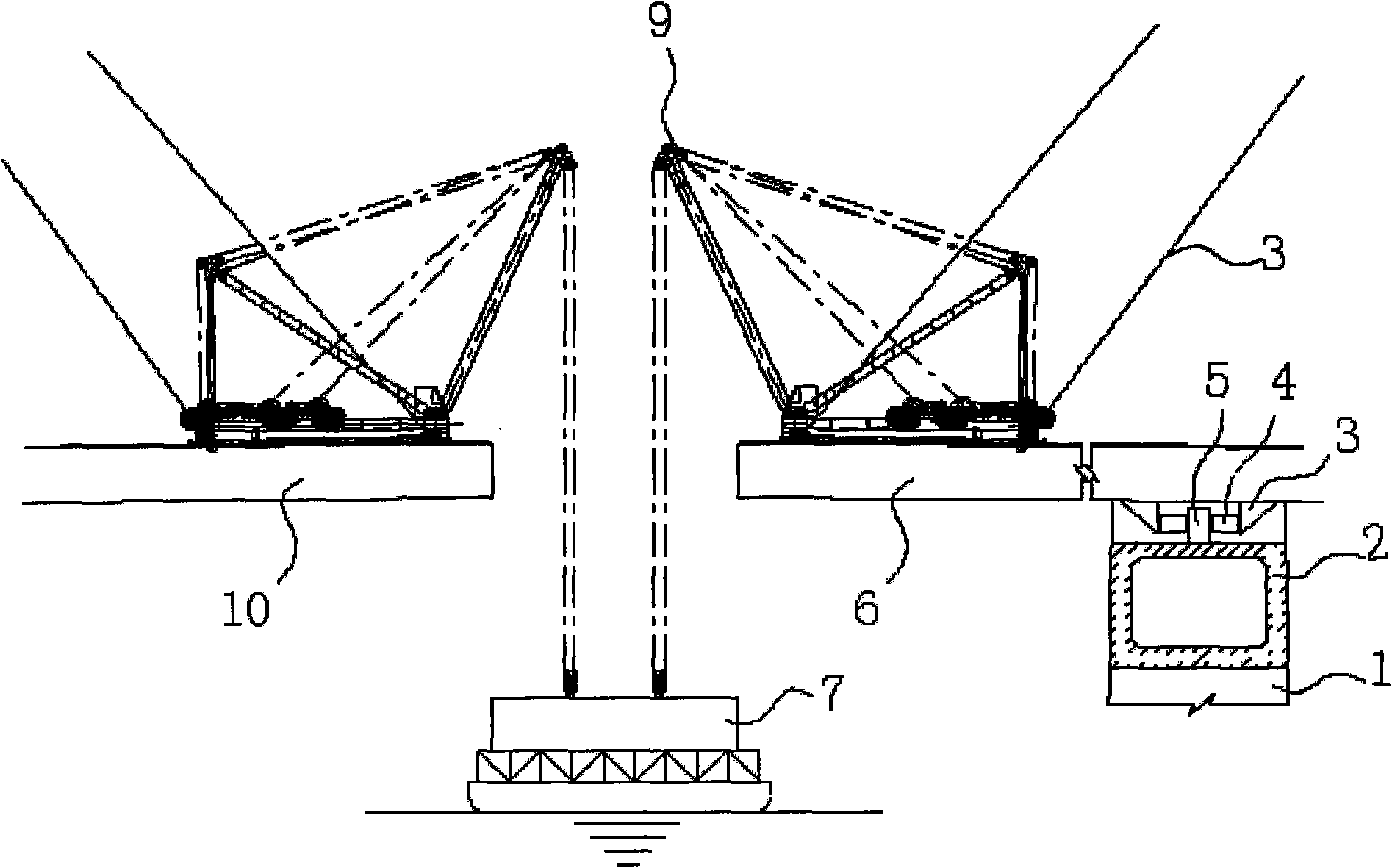

[0013] The construction scheme of the steel box girder mid-span closing method of the cable-stayed bridge of the present invention is as follows figure 1 shown, proceed as follows:

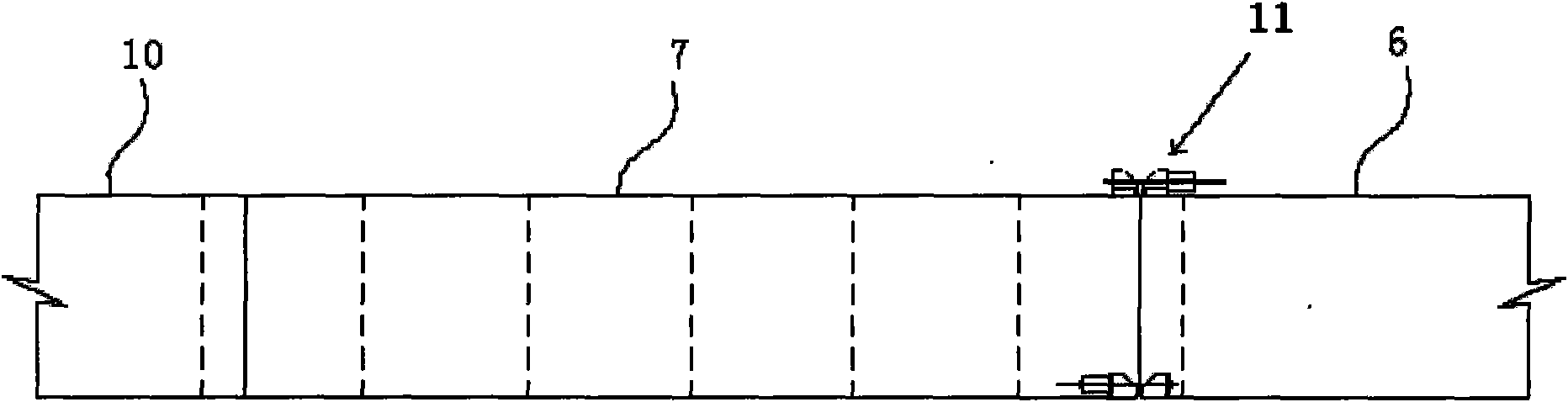

[0014] 1. Complete the installation of the first and second cantilever steel box girders 6 and 10 suspended on the stay cables 8 and located at both ends of the closure;

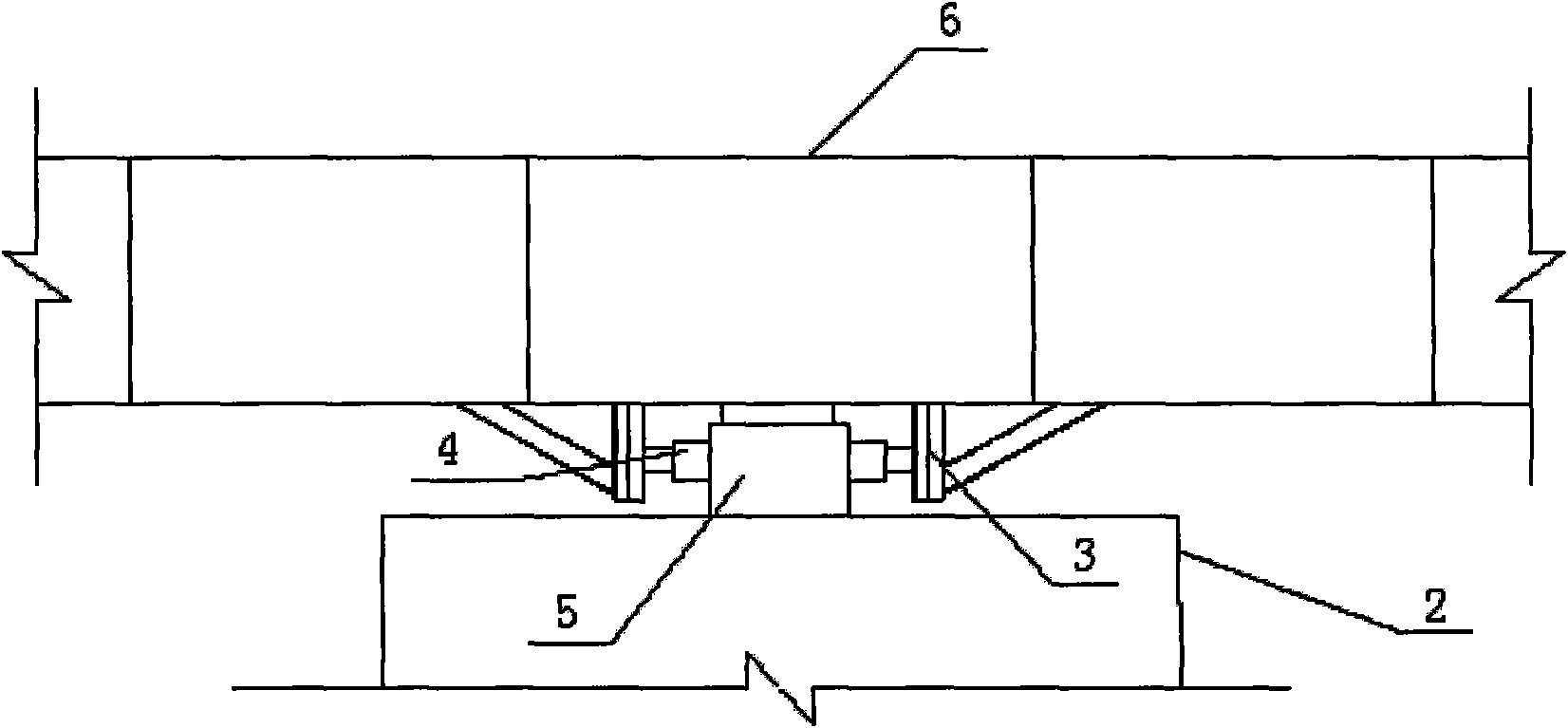

[0015] 2. Before closing, a longitudinal adjustment device for the width of the closing mouth should be installed between the first cantilever steel box girder 6 of the tower area on the side of the closing mouth and the lower beam 2 of the tower column 1, including: at the bottom of the first cantilever beam section 6 The two reaction force frames 3, the reaction force pier 5 that is located on the lower beam 2 of the tower column 1 and is located between the reaction force frames 3, and the reaction force pier 5 that is located between each reaction force frame 3 and the reaction force pier 5 Self-locking large tonnage jack 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com