On-vehicle heater and its manufacturing method

A manufacturing method and heater technology, which are applied in the directions of heating element material, heating element shape, ohmic resistance heating, etc., can solve problems such as leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

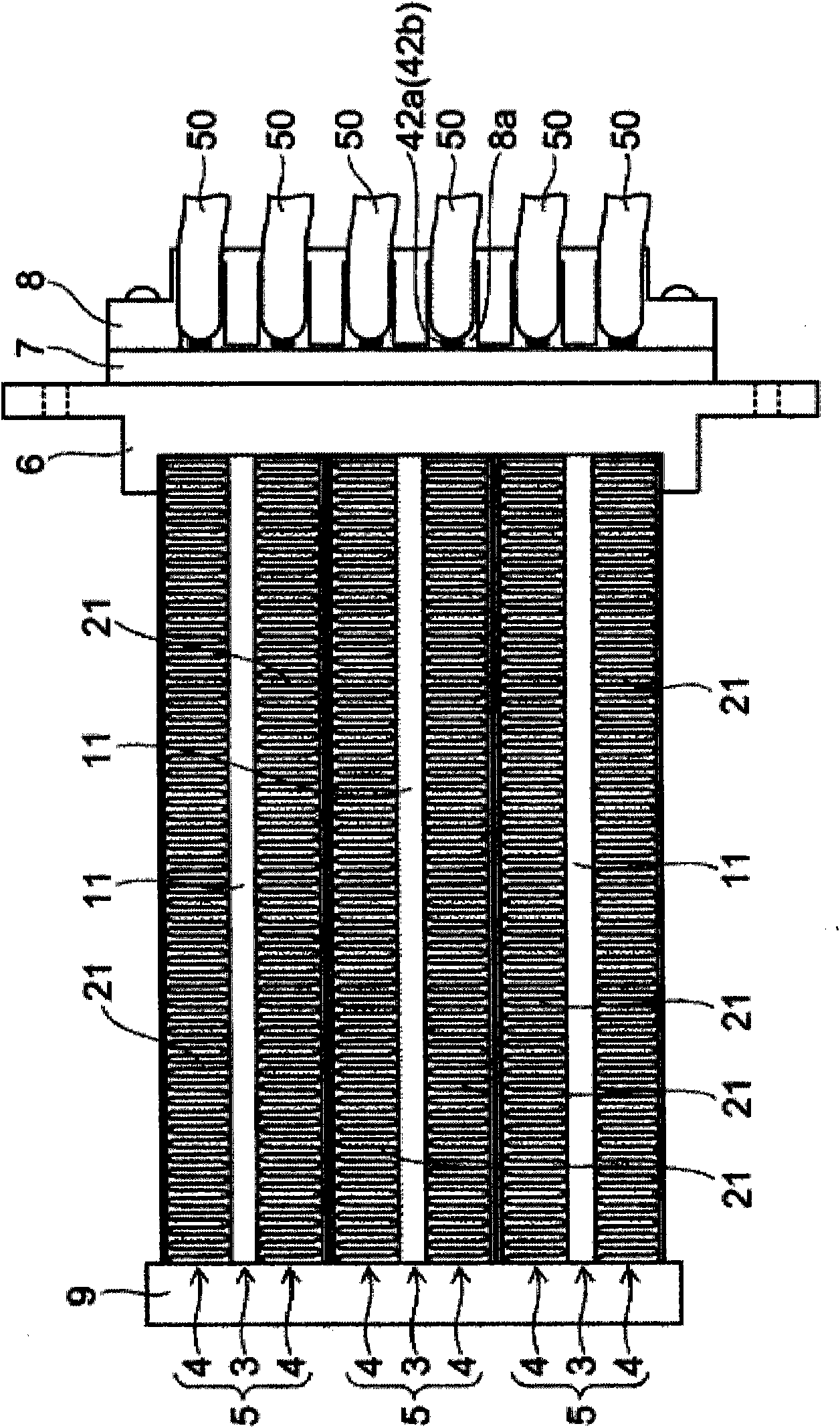

[0021] figure 1 It is a plan view of the vehicle heater according to the embodiment of the present invention.

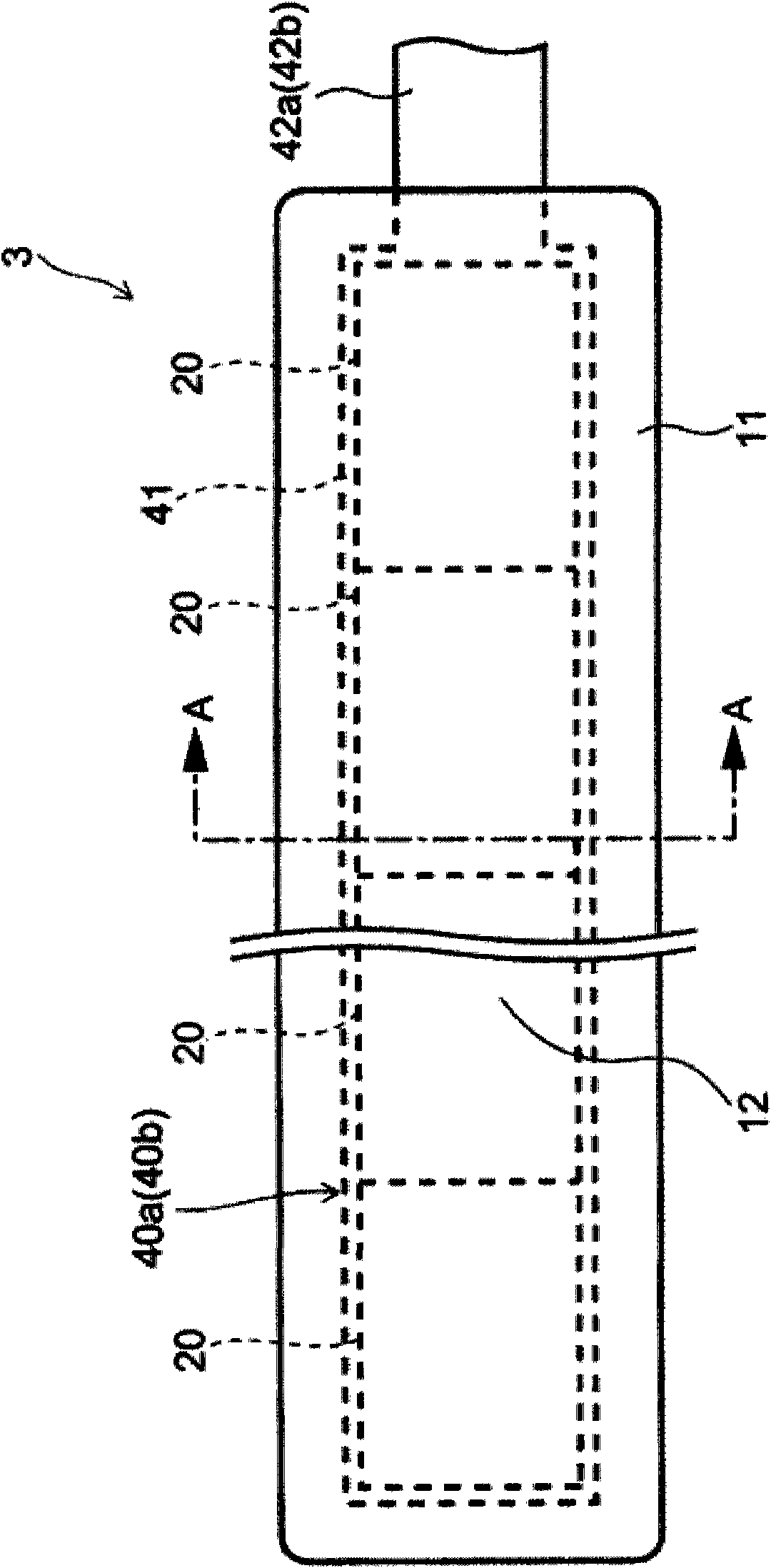

[0022] The vehicle heater of this embodiment has a structure in which a plurality of heating element units 3 containing heating elements inside a cylindrical body 11 and a plurality of heating element units 4 having cooling fins 21 are stacked. For example, one heater unit 5 is constituted by sandwiching one heat generating unit 3 between two heat radiating unit 4 .

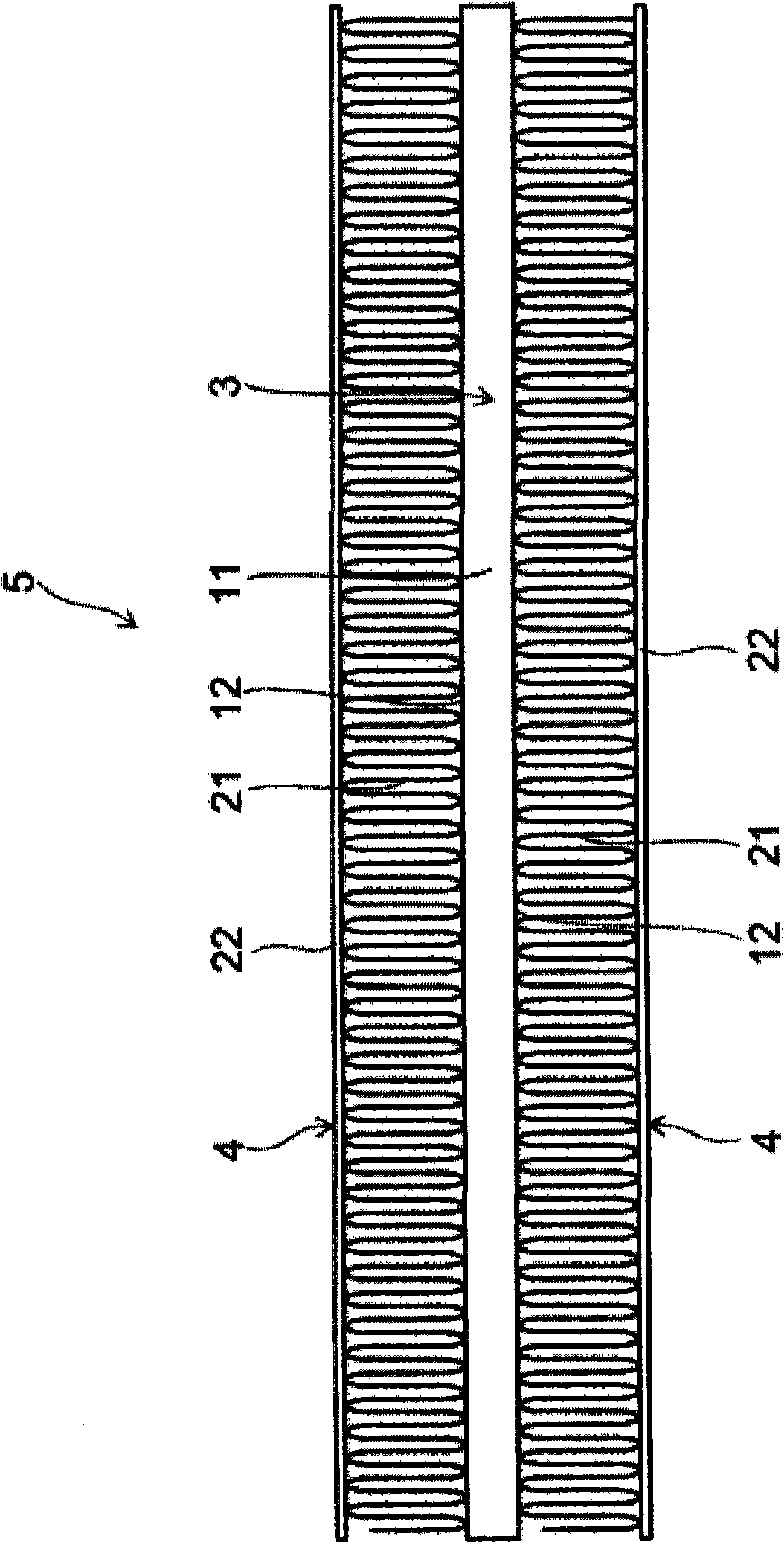

[0023] The vehicle heater of the present embodiment has, for example, a structure in which three heater units 5 are stacked. figure 2 One heater unit 5 is shown enlarged and extracted.

[0024] The heat radiator unit 4 has a heat sink 21 and a metal plate 22 . The heat sink 21 is configured by bending a plate made of, for example, aluminum in a zigzag shape, and is provided between the metal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap