Self-locking drum-shaped blind rivet

A blind rivet and drum-shaped technology, applied in rivets and other directions, can solve the problems of reduced shear force of rivets and riveted parts, and achieve the effect of improved resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

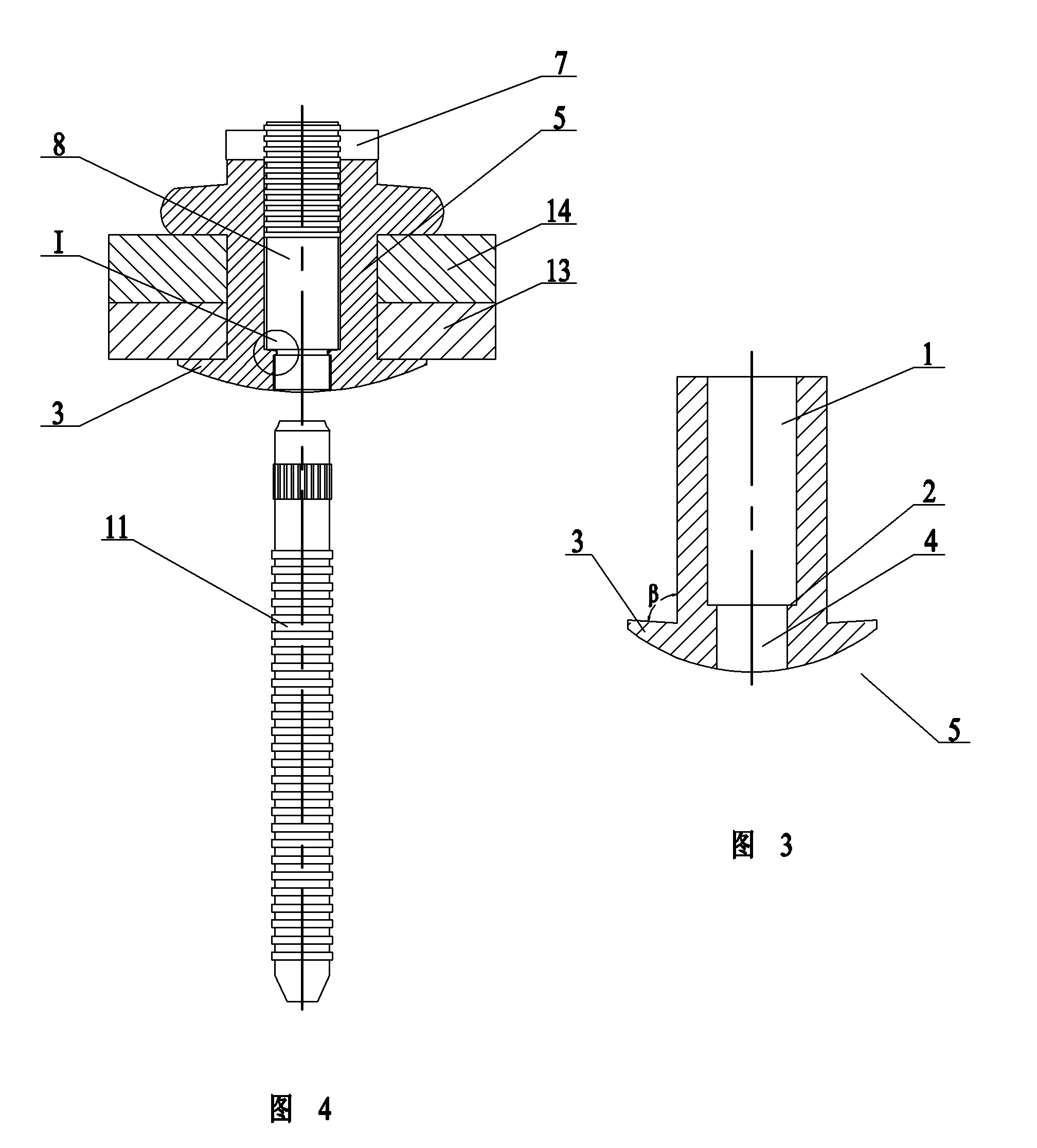

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

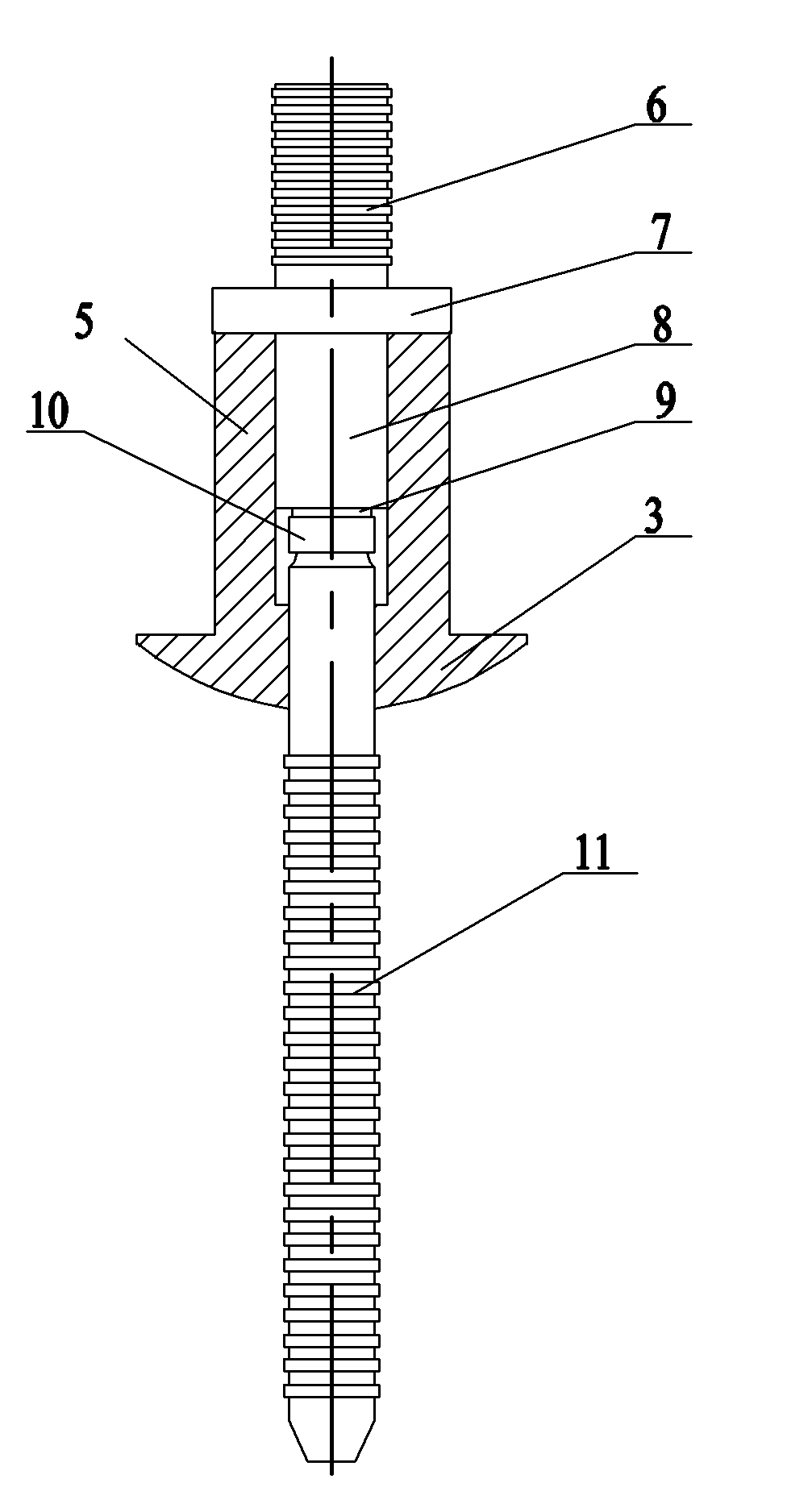

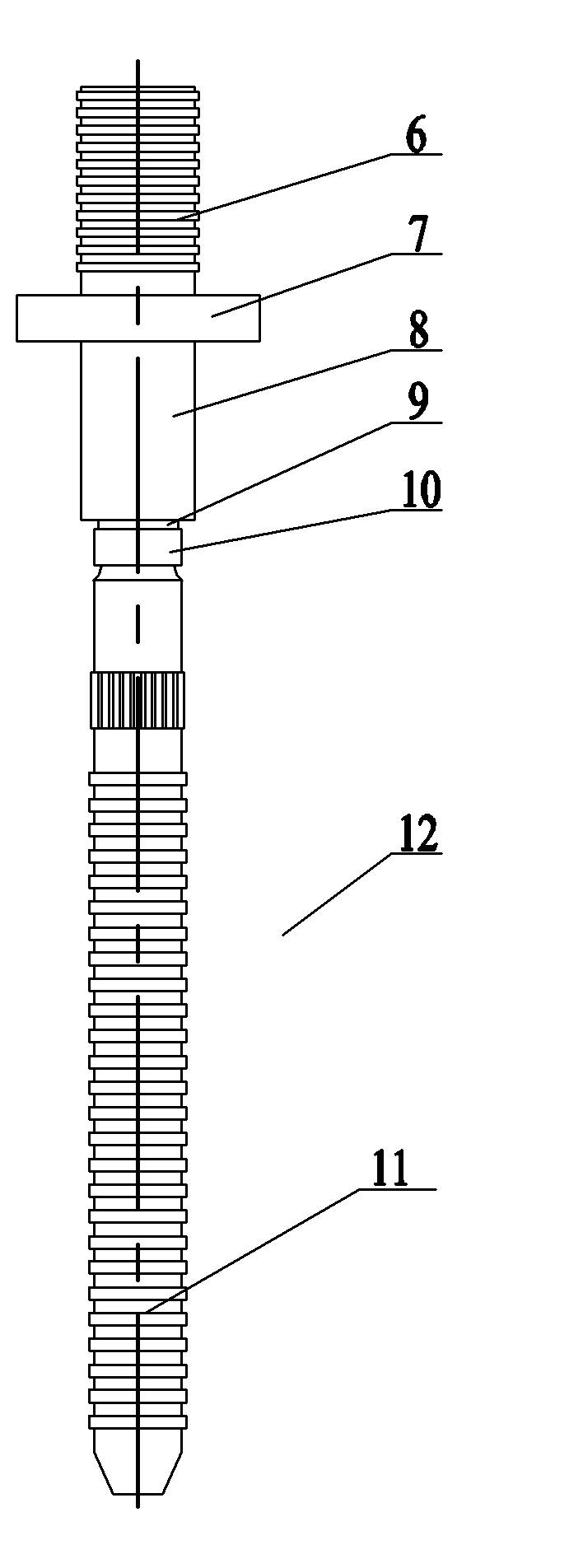

[0018] Such as Figure 1~Figure 6 As shown: the present invention includes a first inner hole 1, a locking step 2, a riveting edge 3, a second inner hole 4, a nail body 5, a parallel thread 6, a nail head 7, a first cylinder 8, and a locking groove 9 , the second cylinder 10 , the force receiving portion 11 , the mandrel 12 , the first riveting object 13 and the second riveting object 14 .

[0019] Such as figure 1 , figure 2 with image 3 As shown: the nail body 5 is provided with a first inner hole 1 and a second inner hole 4 distributed along the axial direction of the nail body 5, and the first inner hole 1 and the second inner hole 4 communicate with each other. 5 through holes are formed. The first inner hole 1 and the second inner hole 4 are located at the two ends of the nail body 5 respectively, the aperture of the first inner hole 1 is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com