Fireproof valve capable of realizing automatic and quick close in case of failed electronic installations

A technology of valves and facilities, applied in the field of fire prevention valves, which can solve the problems that operators are difficult to close the valves in the fire scene, lose the ability to drive and control the valves, and cannot close the valves, etc., and achieve the effects of wide application range, simple structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

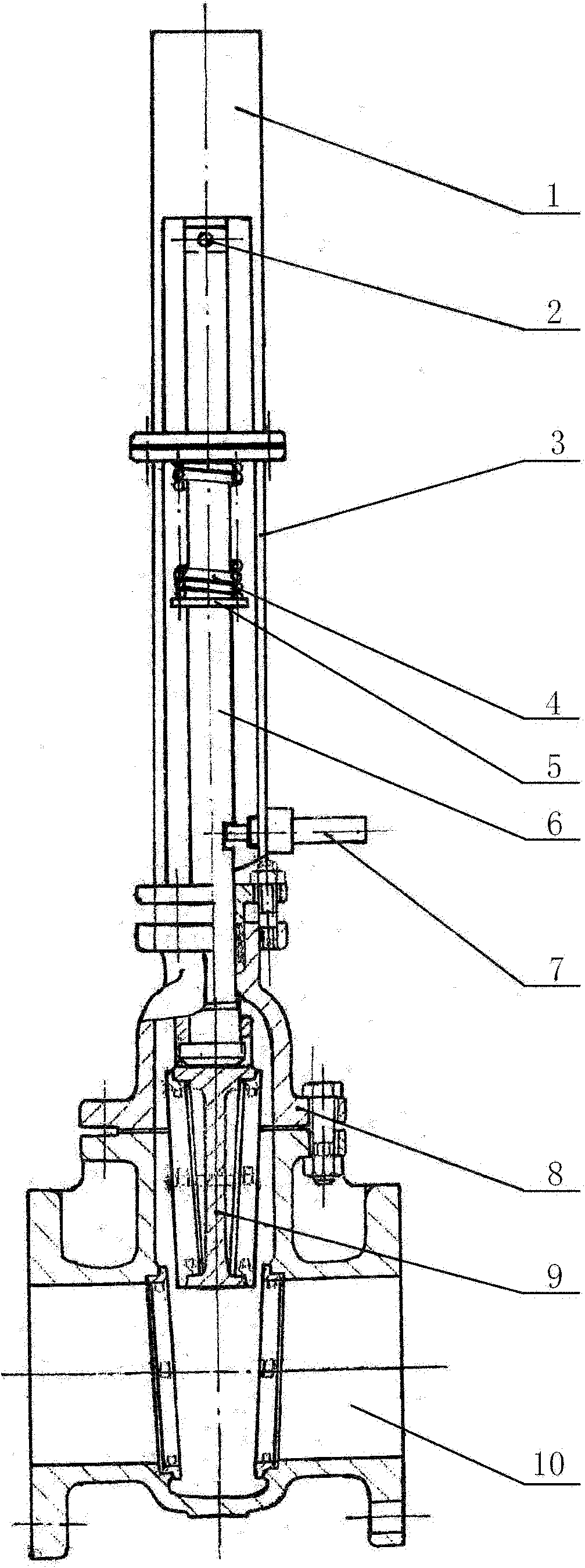

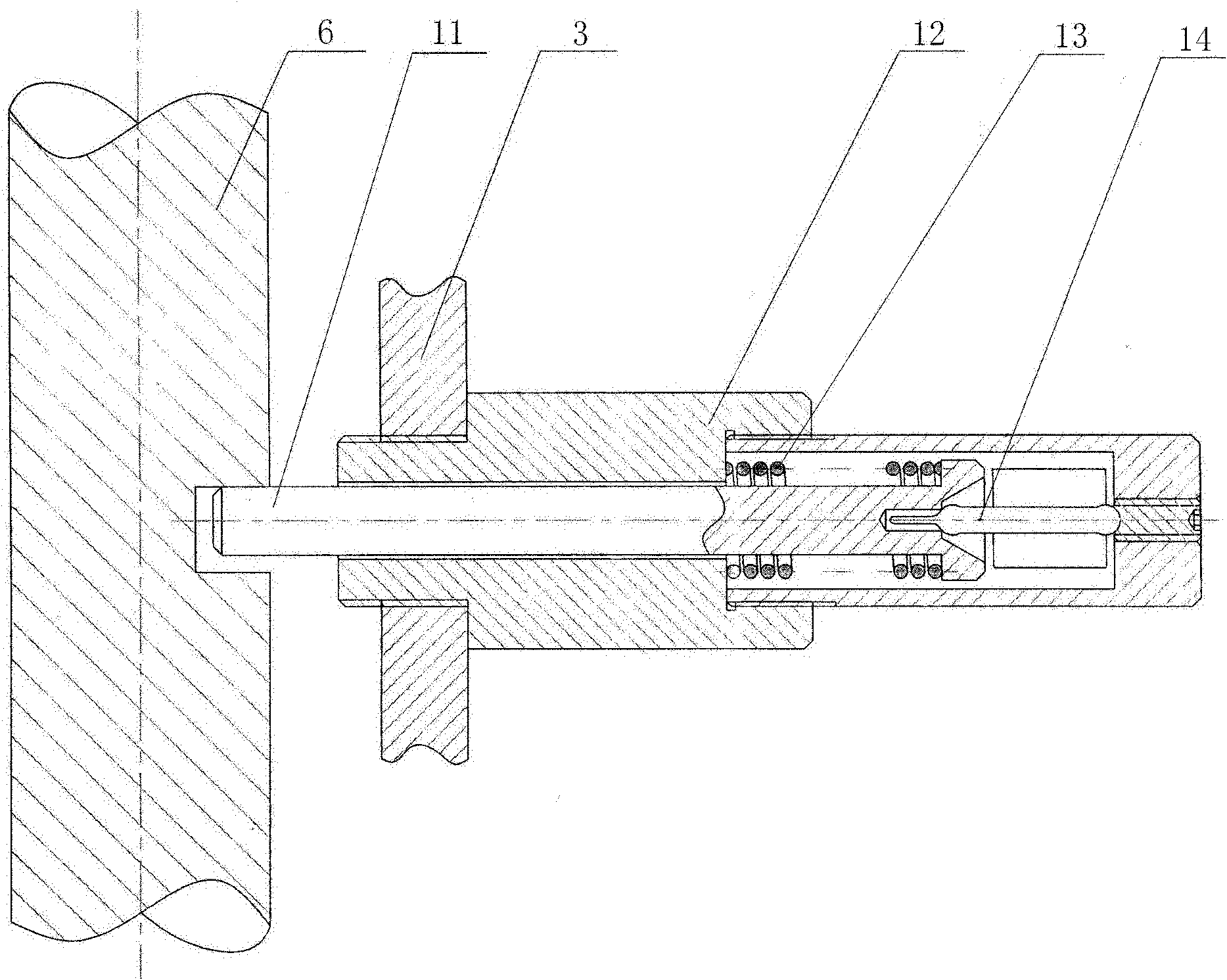

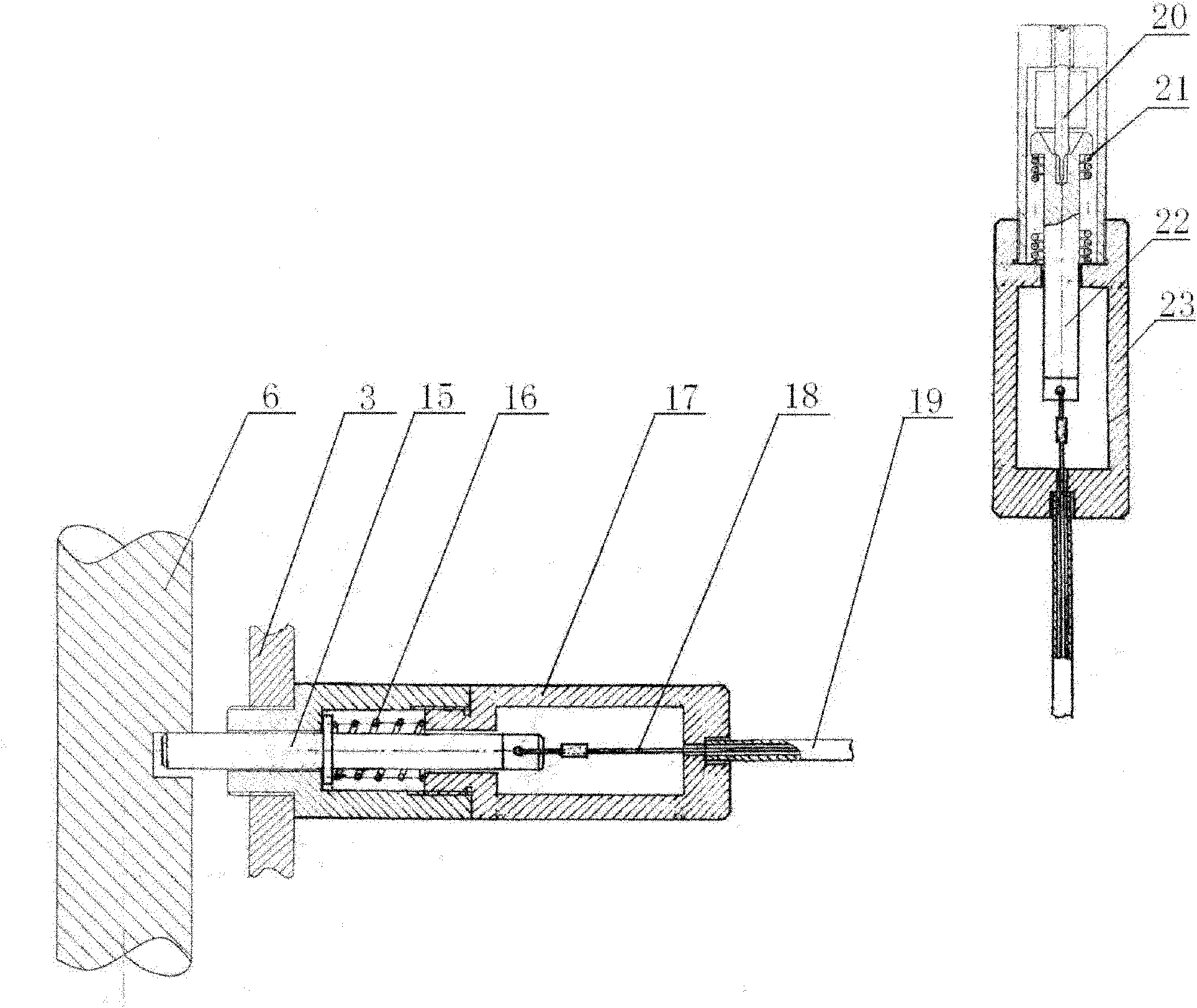

[0022] A fire valve that automatically and quickly closes in the event of failure of a power-damaged facility, such as figure 1 As shown, including valve body 10, valve core 9, valve cover 8, valve stem 6, valve bracket 3 and valve stem reset mechanism 1, the valve cover is coaxially installed on the valve body, and the valve bracket is coaxially installed on the valve cover, The valve stem reset mechanism is coaxially installed on the valve bracket, and the valve core is a knife gate valve core. When the spool moves up to the top of the valve body, the valve is in an open state, and when the spool moves down to the bottom, the valve is in a closed state. An ESFR quick response system 7 is installed horizontally on the side wall of the valve bracket, and the front end of the ESFR quick response system is embedded on the side wall of the valve stem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com