Humidity adjusting method for constant humidity cabinet

A technology of humidity regulation and humidity, which is applied in the direction of humidity control, control/regulation system, non-electric variable control, etc. It can solve the problem that the humidity regulator is difficult to meet the predetermined requirements, the requirements of special environmental humidity cannot be guaranteed, and the humidity capacity of the humidity conditioner is limited. and other problems, to achieve the effect of improving moisture absorption and desorption performance, improving humidity control performance, and high humidity control rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

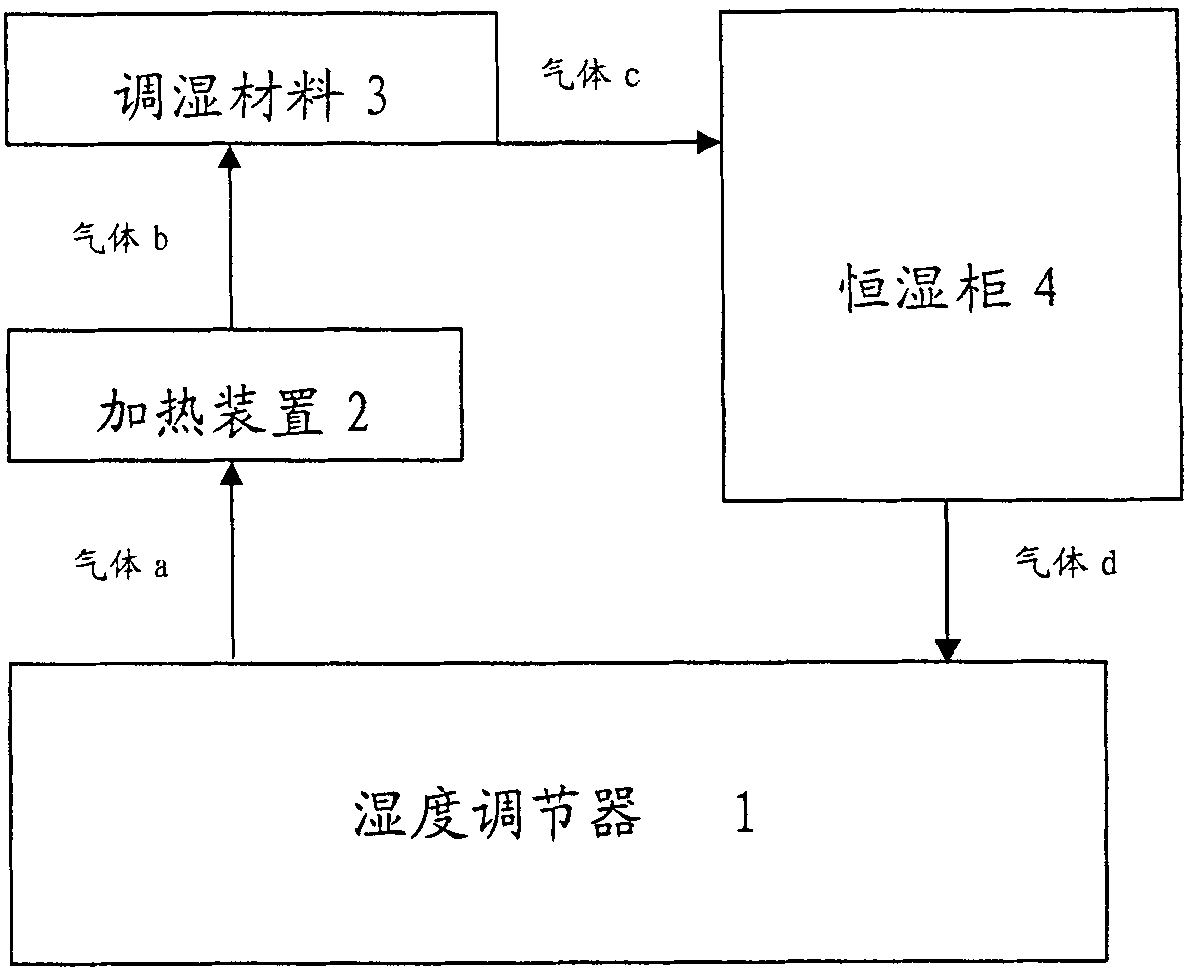

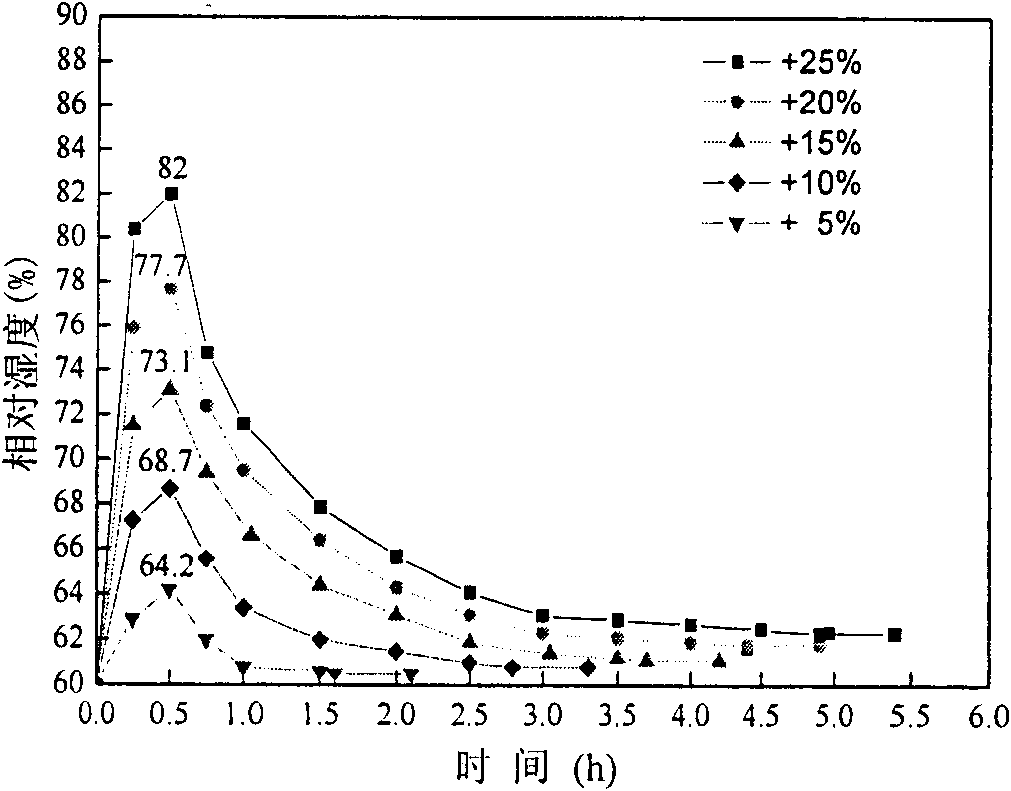

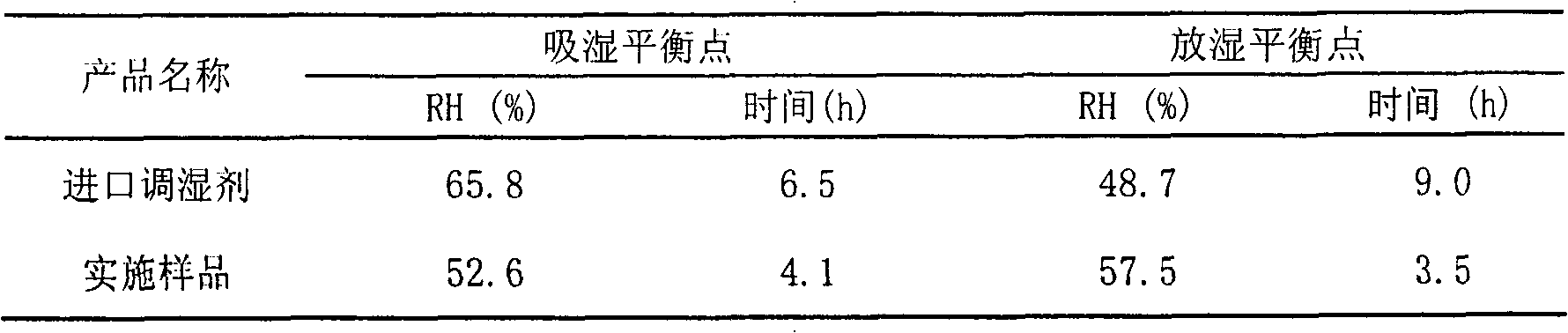

[0028]A humidity control method for a constant humidity cabinet, characterized in that: the humidity regulator 1 is turned on when the operator goes to work, and is closed when the humidity regulator 1 is off work in the afternoon; during the working period of the humidity regulator 1, the humidity regulator 1 performs humidity control on the constant humidity cabinet 4, When the humidity regulator 1 is closed, the humidity control agent 3 is used to control the humidity of the constant humidity cabinet 4; when the humidity regulator 1 is in the working state, the gas after the humidity conditioning treatment by the humidity regulator 1 is first heated by the heating device 2, and then heated. The final gas passes through the humidity conditioner 3, and the gas enters the constant humidity cabinet 4 after contacting the humidity conditioner to adjust the humidity in the cabinet, and then the gas is pumped back into the humidity regulator 1, and the humidity regulator 1 again Ca...

Embodiment 2

[0035] A humidity control method for a constant humidity cabinet, characterized in that: the humidity regulator 1 is turned on when the operator goes to work, and is closed when the humidity regulator 1 is off work in the afternoon; during the working period of the humidity regulator 1, the humidity regulator 1 performs humidity control on the constant humidity cabinet 4, When the humidity regulator 1 is closed, the humidity control agent 3 is used to control the humidity of the constant humidity cabinet 4; when the humidity regulator 1 is in the working state, the gas after the humidity conditioning treatment by the humidity regulator 1 is first heated by the heating device 2, and then heated. The final gas passes through the humidity conditioner 3, and the gas enters the constant humidity cabinet 4 after contacting the humidity conditioner to adjust the humidity in the cabinet, and then the gas is pumped back into the humidity regulator 1, and the humidity regulator 1 again C...

Embodiment 3

[0042] A humidity control method for a constant humidity cabinet, characterized in that: the humidity regulator 1 is turned on when the operator goes to get off work, and is closed when the humidity regulator 1 is off work in the afternoon; during the working period of the humidity regulator 1, the humidity regulator 1 performs humidity control on the constant humidity cabinet 4, When the humidity regulator 1 is closed, the humidity control agent 3 controls the humidity of the constant humidity cabinet 4; when the humidity regulator 1 is in the working state, the gas after the humidity conditioning treatment by the humidity regulator 1 is first heated by the heating device 2, and then heated. The final gas passes through the humidity conditioner 3, and the gas enters the constant humidity cabinet 4 after contacting the humidity conditioner to adjust the humidity in the cabinet, and then the gas is pumped back into the humidity regulator 1, and the humidity regulator 1 again Carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com