Straight rotary linkage core puller for injection mold of elbow product

A technology of injection mold and core-pulling mechanism, which is applied to household appliances, tubular items, other household appliances, etc., can solve the problems of occupation of labor, low production efficiency, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

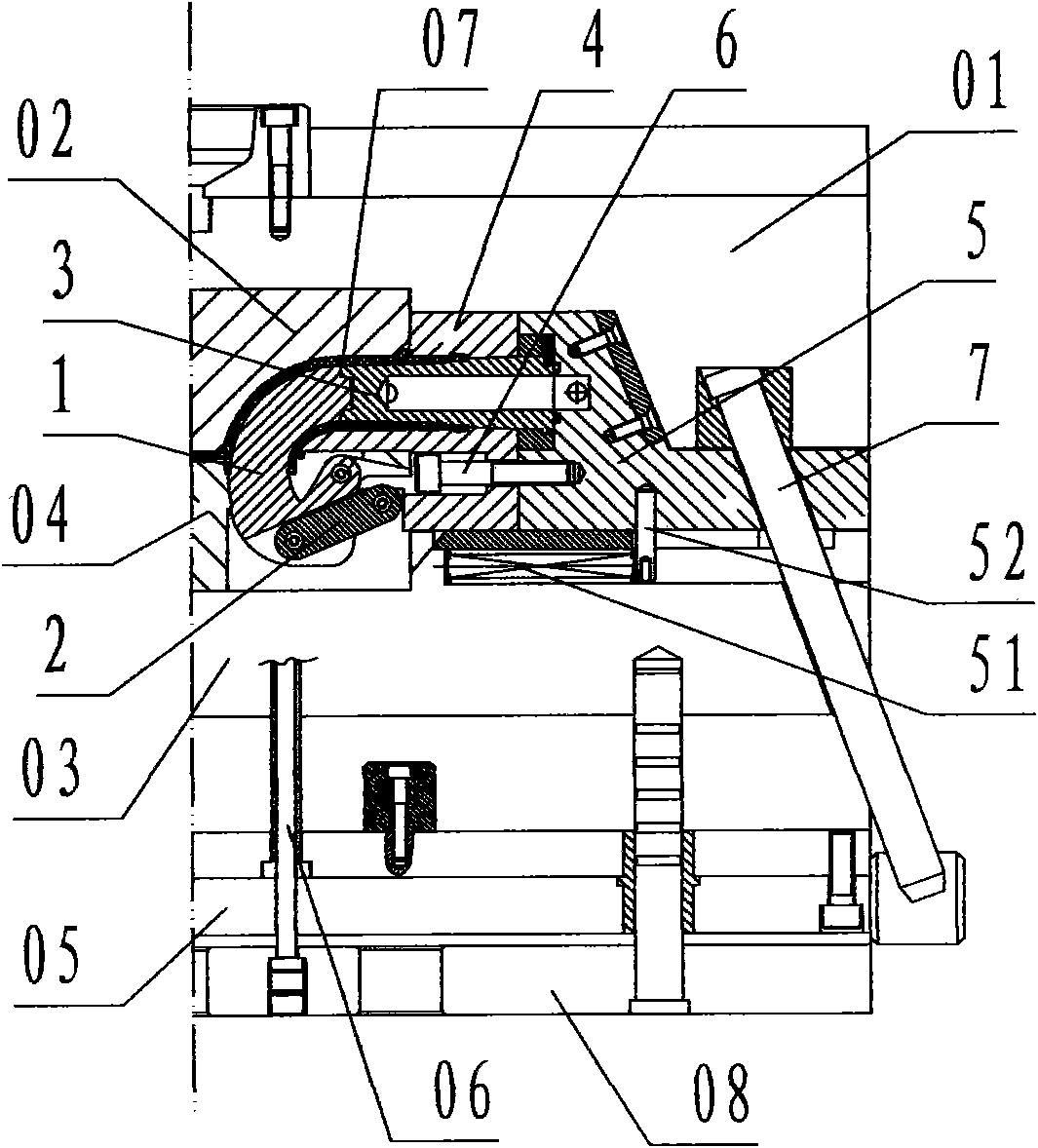

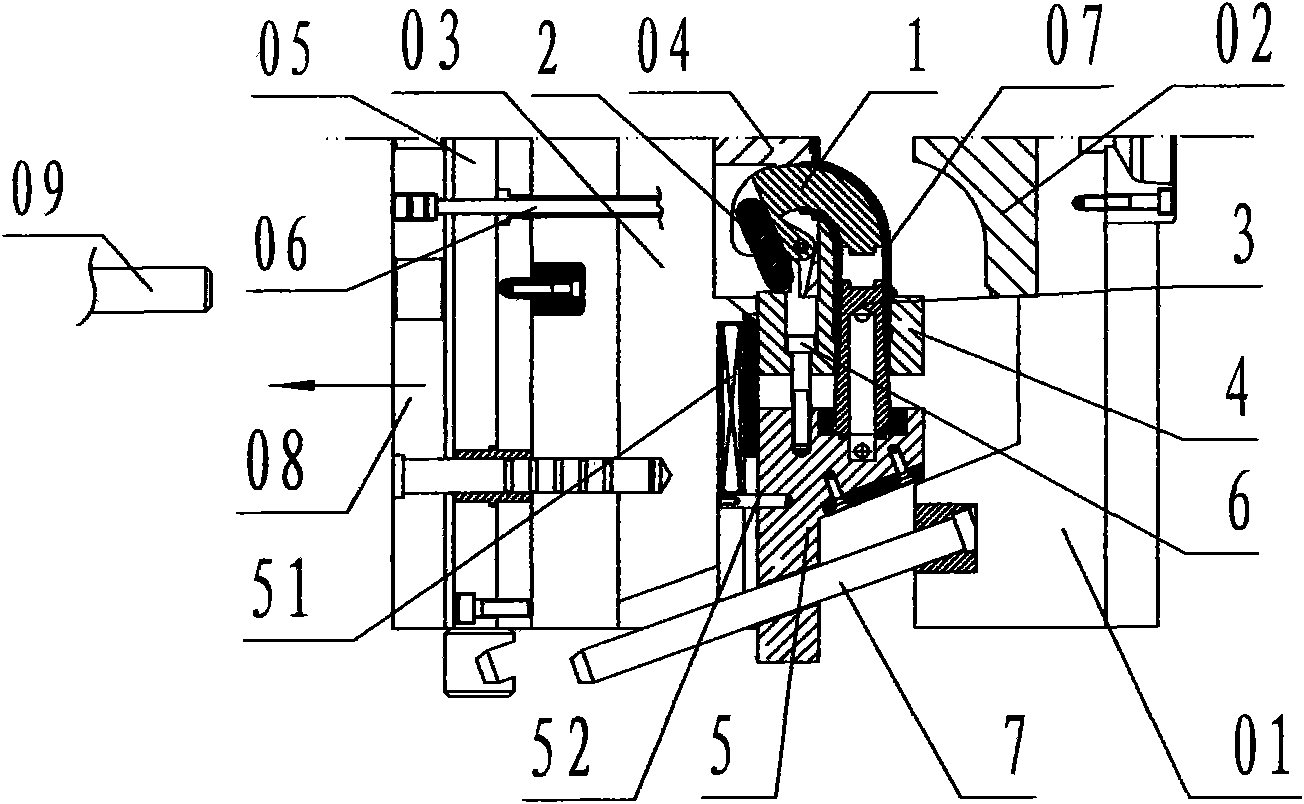

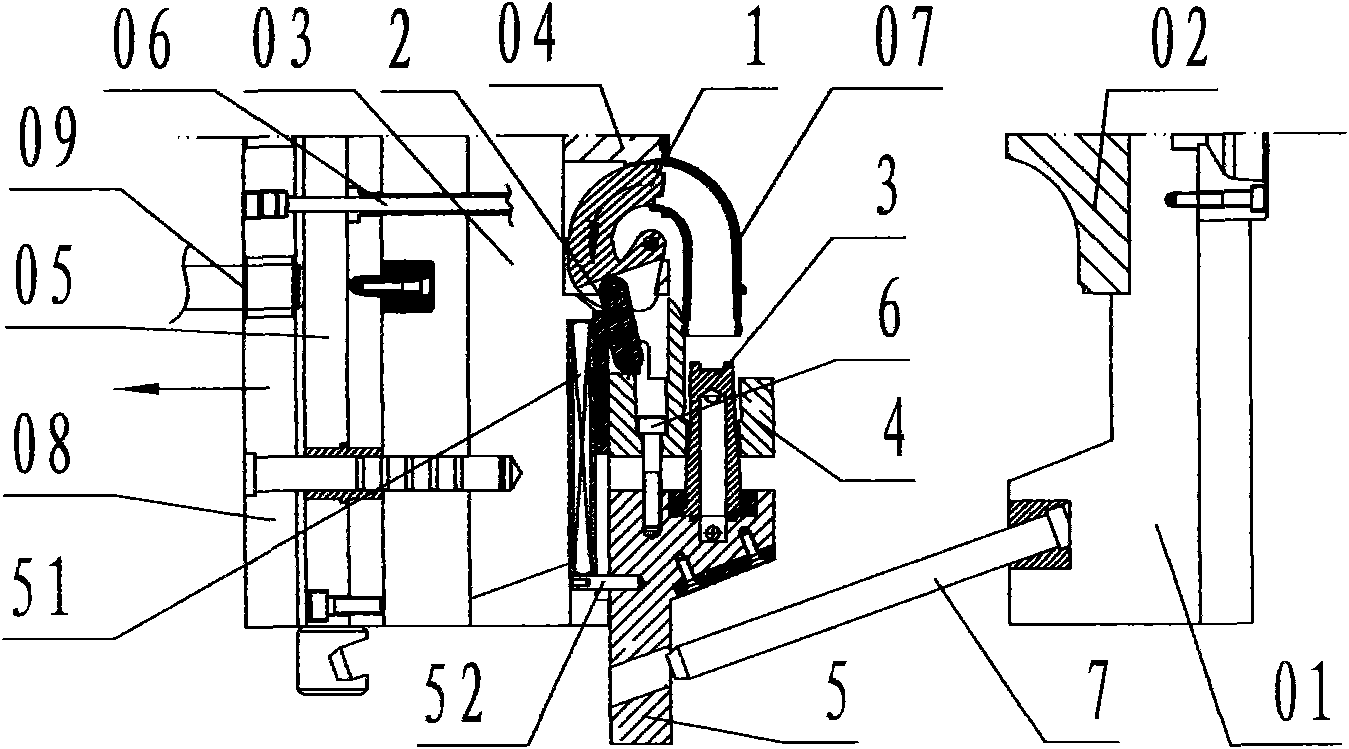

[0027] refer to Figure 1 to Figure 4, a straight rotation linkage core-pulling mechanism of an elbow product injection mold according to the present invention, including an inner curved core-pulling 1, a connecting rod 2, an inner straight core-pulling 3, an outer straight core-pulling 4, an inclined guide slider 5, a late Pull rod 6, inclined guide post 7, wherein: the inner curved core pulling 1 is a G-shaped hook-shaped steel member; the upper half of the inner curved core pulling is a curved section, and the lower half of the inner bending core pulling is Hook-shaped section; the curved section of the inner curved core-pulling is circular in cross-section, conforms to the shape of the inner wall of the pipe at the bending part of the elbow product 07, and coincides with the arc axis of the inner wall of the pipe at the bending part of the elbow product 07, The part that bends 1 / 4 of the central angle along the arc axis, the end surface of the curved section is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com