Automobile hydraulic jack endurance test device and test method thereof

A hydraulic jack and durability test technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., to achieve the effect of accurate test data, simple structure, and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

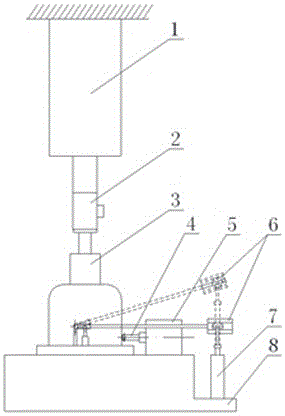

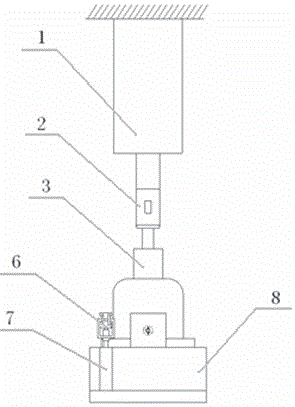

[0032] Such as figure 1 and 2 As shown, the automobile hydraulic jack durability test device of the present invention: the device includes a workbench, a loading part fixed on one end of the workbench and loading the automobile hydraulic jack to be tested; a driving part fixed on the other side of the workbench, The driving part is that the driving force is transmitted to the automobile hydraulic jack to be tested through the operating rod; the rotating cylinder installed at the bottom of the automobile hydraulic jack is the pressure relief part; test.

[0033] Test sample installation and debugging technical scheme: The automobile hydraulic jack test sample is placed on the workbench of the test device, and the upper and lower ends of the sensor are in contact with the top end face of the lifting rod of the automobile hydraulic jack and the end face of the loading cylinder to apply pressure. And ensure the same vertical center line, the drive part fixed on the other side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com