Piling and pushing mechanism and piling and pushing method for mahjong machine

A technology of mahjong machine and push method, which is applied in sports accessories, indoor games, etc., and can solve the problems of unstable and reliable making of cards, and inability to switch freely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

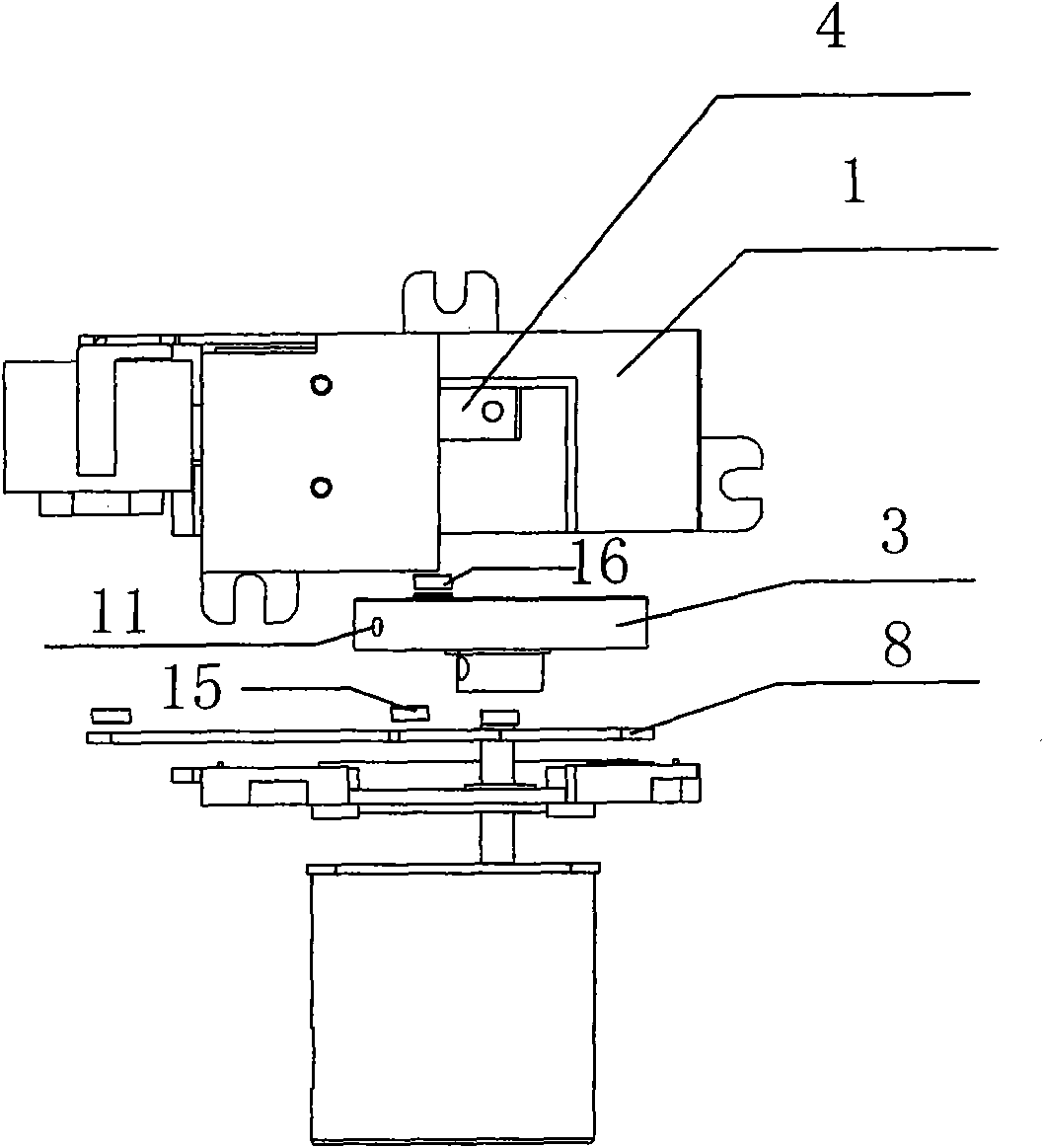

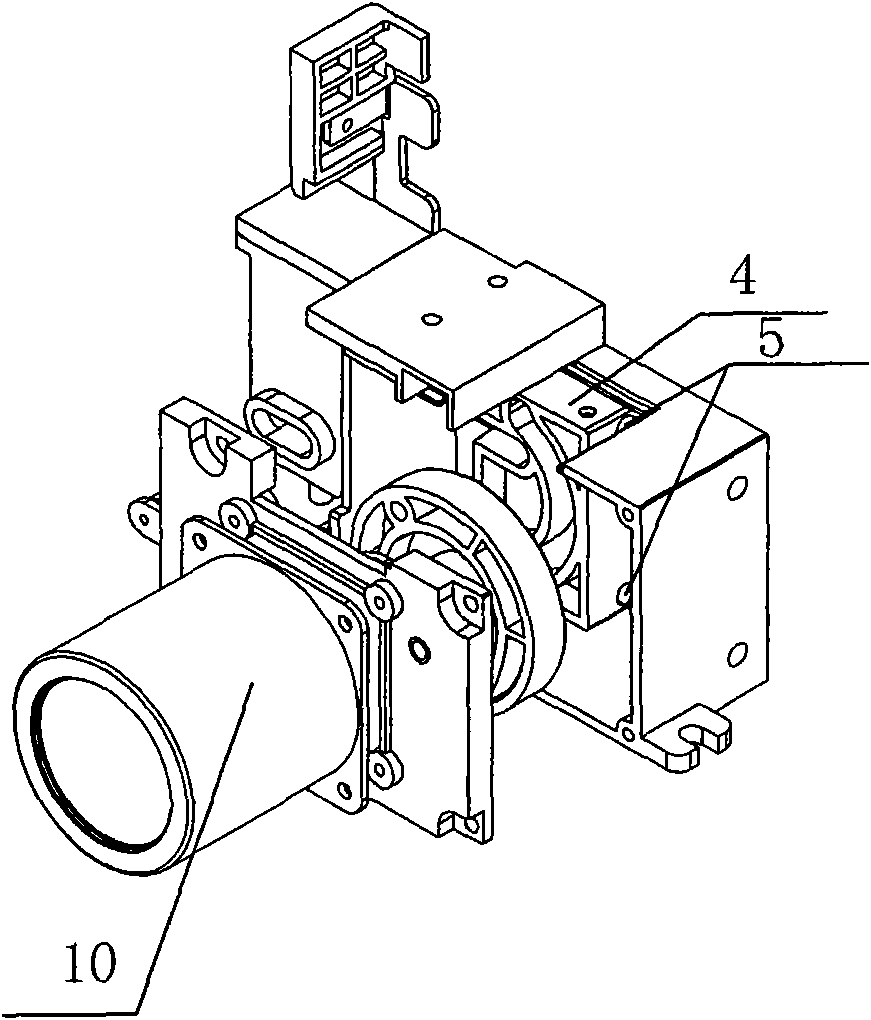

[0036] Used as a four-port machine, such as Figure 9 and Figure 10As shown, when two boards are needed for every trick; the motor drives the driving wheel 3 to rotate, and the bearing A15 on the driving lever 8 moves up and down, driving the card receiving seat 7 that the other end of the driving lever 8 is connected to move up and down; When the Hall sensor is in the matching position (when point A is at a high position), the motor 10 stops, the stack pusher is at the first card receiving position, the card delivery mechanism sends a card to the card receiving seat 7, and the stack push mechanism electric control device Perceive the arrival of a card to control the rotation of the motor 10; when the magnet B12 moves to a position cooperating with the Hall sensor (when the B point is at a high position), the motor 10 stops, and the stack push is in the second card receiving position, and the card delivery mechanism will move to the second card receiving position. A card is ...

Embodiment 2

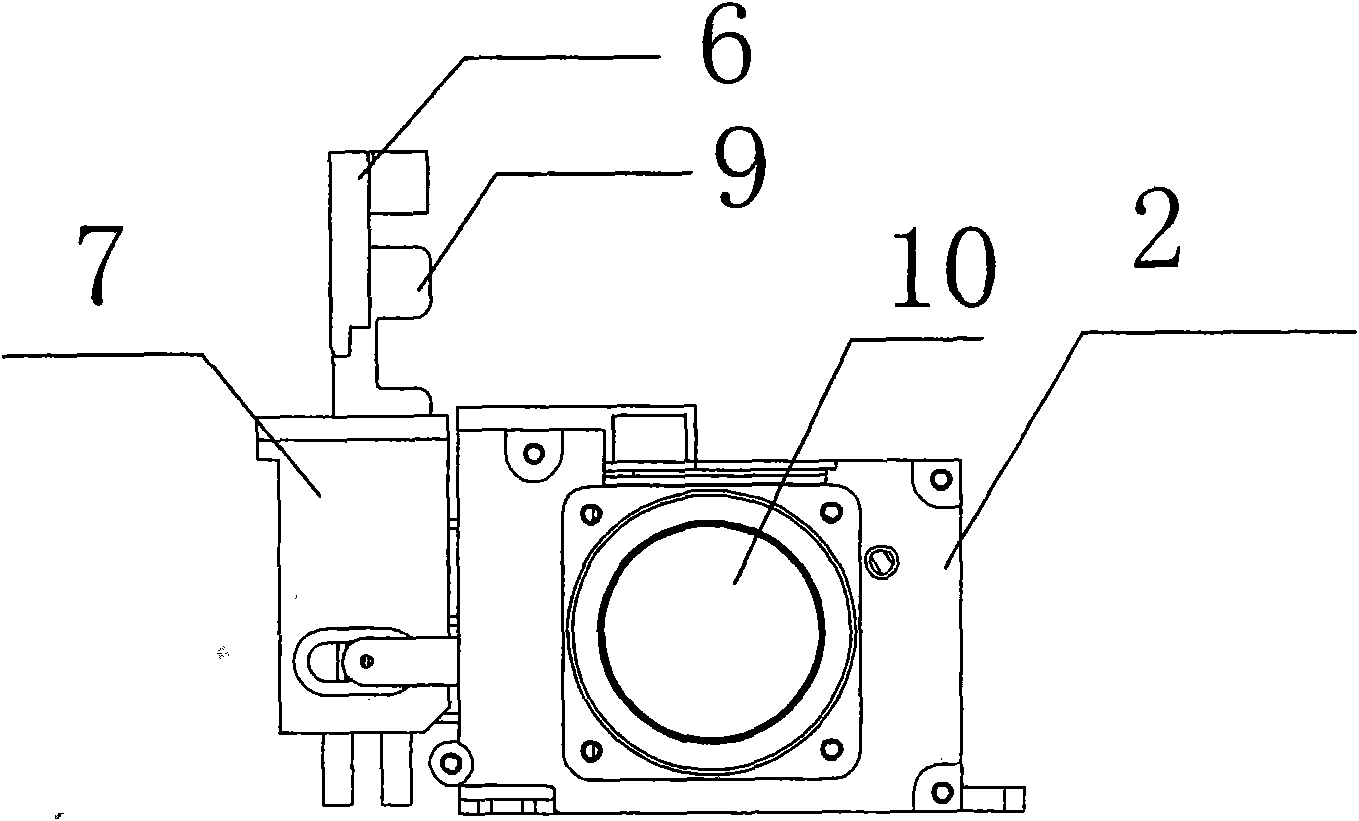

[0038] Used as an eight-port machine, such as Figure 6-Figure 7 As shown, when one card is needed for each trick; the motor 10 rotates, and when the magnet A11 moves to the position matched with the Hall sensor (when point A is at a high position), the motor 10 stops, and the stack push is at the first card receiving position , the card delivery mechanism sends a card to the card receiving seat 7, and the electric control device of the stacking mechanism senses the arrival of the card to control the motor 10 to rotate and rotate to the position of pushing the card (crossing points B and C). A card required by the mouth machine is pushed away from the stacking mechanism to prepare for receiving cards for the next trick;

[0039] Used as an eight-port machine, such as Figure 12-Figure 13 As shown, when three cards are needed for each trick, the motor 10 rotates, and when the magnet A11 moves to a position matching with the Hall sensor (when point A is at a high position), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com