Pressure machine

A mechanical and pressure technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of uneconomical and inability to change the slider action freely, and achieve the effect of easy management and easy operation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

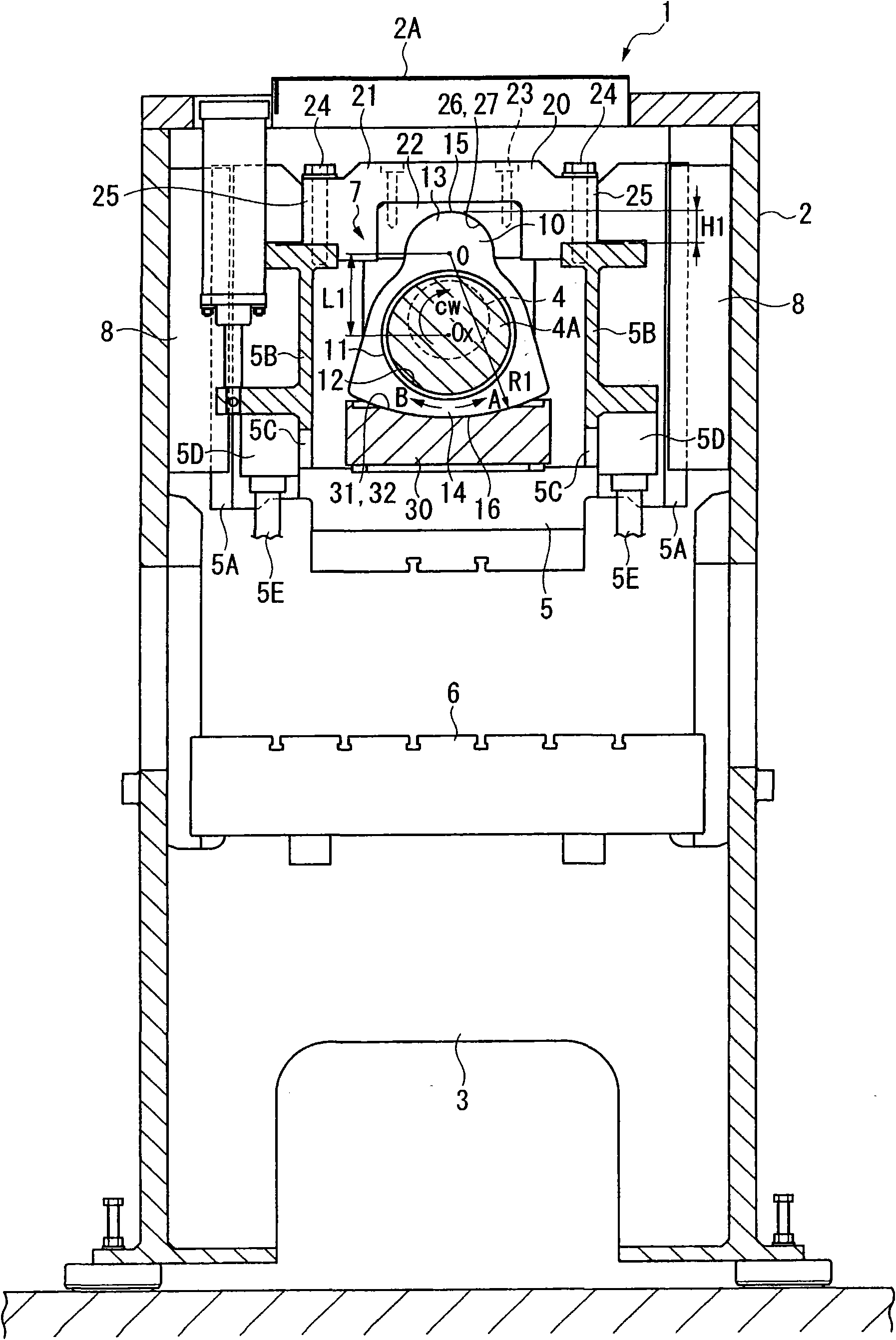

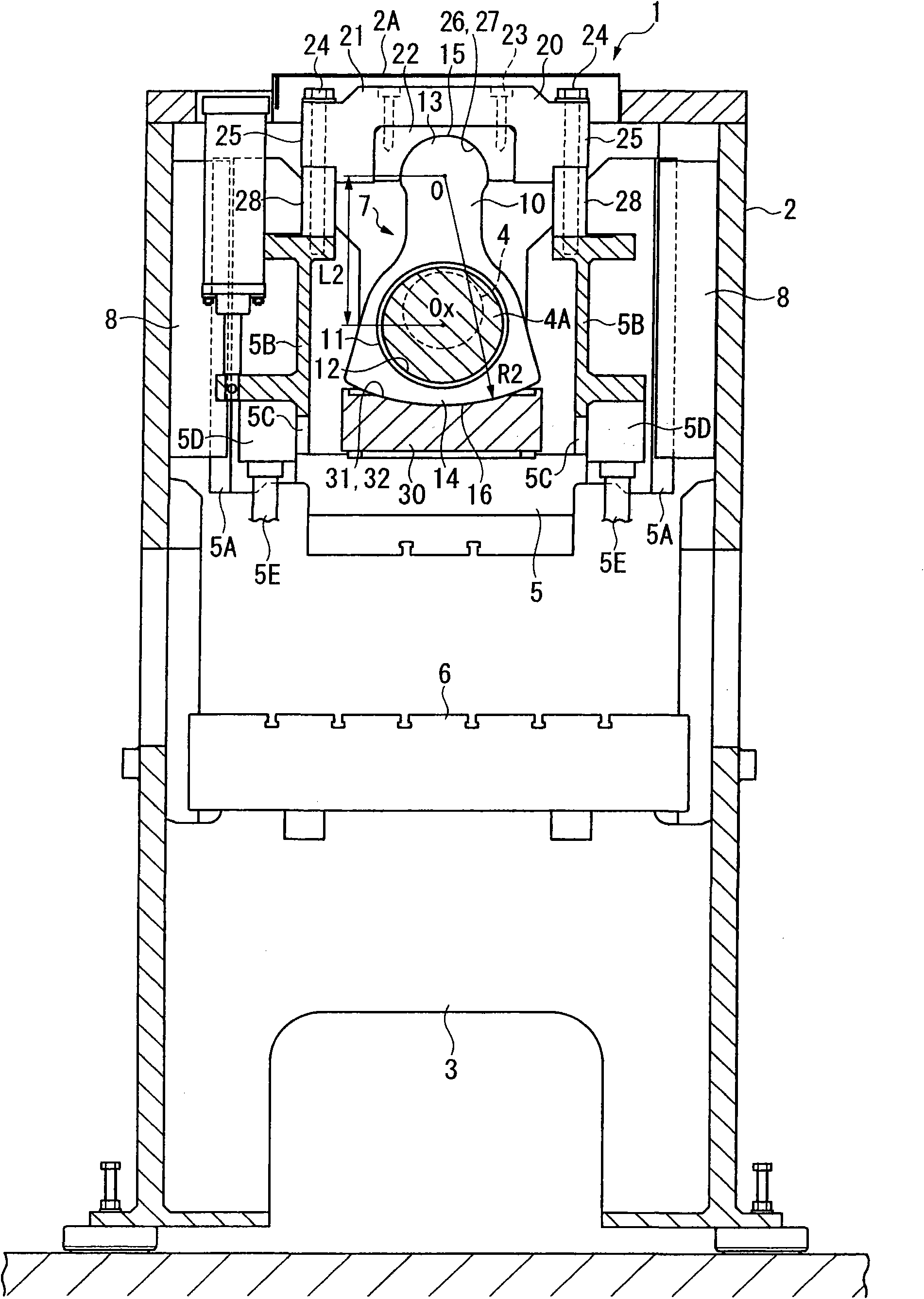

[0018] Hereinafter, an embodiment of the present invention will be described based on the drawings.

[0019] figure 1 Among them, the press machine 1 is a relatively small press machine with a pressure capacity ranging from tens of tons to tens of tons. Specifically, it includes: a frame 2 composed of a pair of metal plates erected on the left and right sides in the figure, A box-shaped base 3 composed of front and rear metal plates straddling the lower part of the frame 2, a shaft support part composed of front and rear metal plates (not shown) straddling the upper part of the frame 2, and an insertion shaft The main shaft 4 of the supporting part, the bottomed box-shaped slider 5 driven by the rotation of the main shaft 4 , and the backing plate 6 arranged on the upper part of the base 3 , and the rotation of the main shaft 4 is transmitted to the slider 5 through the swing rod drive mechanism 7 .

[0020] On the upper side of the frame 2, on the left and right inner wall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com