Unfreezing device for a railway coal conveying carriage

A technology for carriages and coal conveying, which is applied to the field of ice breaking devices for railway coal conveying carriages, can solve the problems of long coal unloading time, high cost, high labor intensity of manual operation, etc., and achieves the effects of reducing electric power consumption, saving electric energy and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

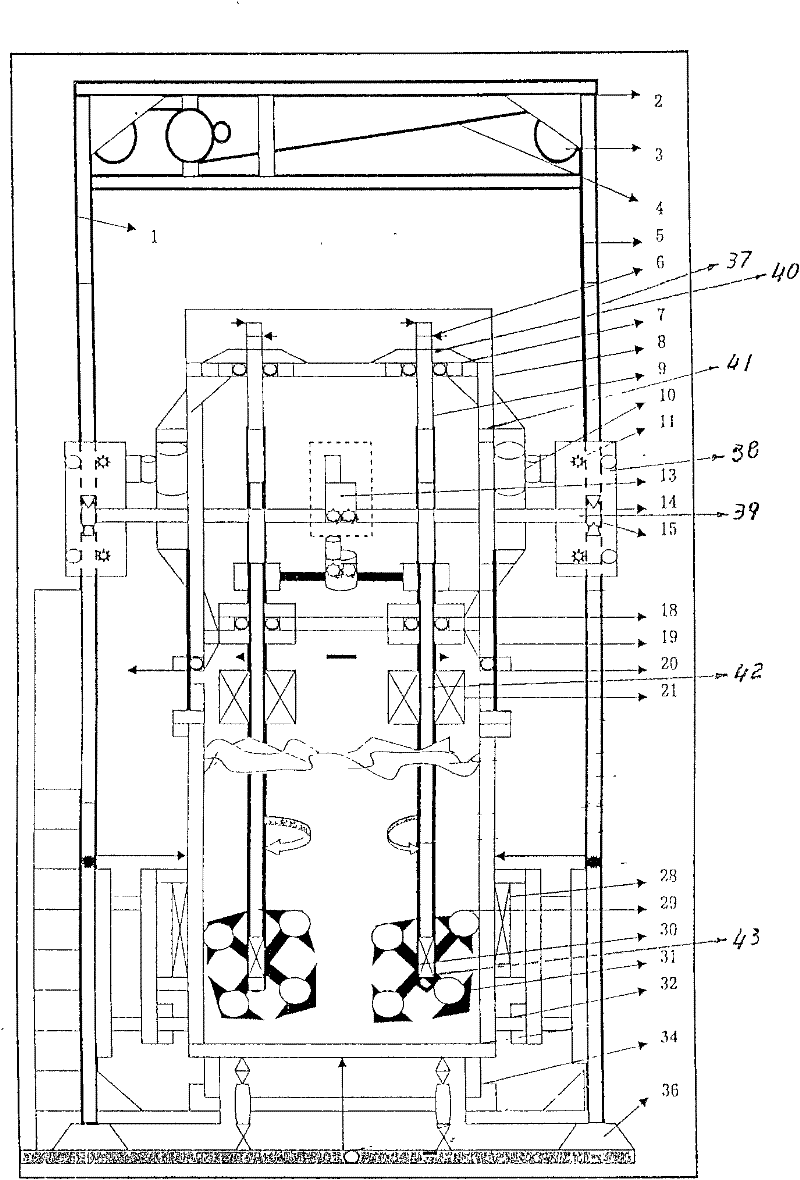

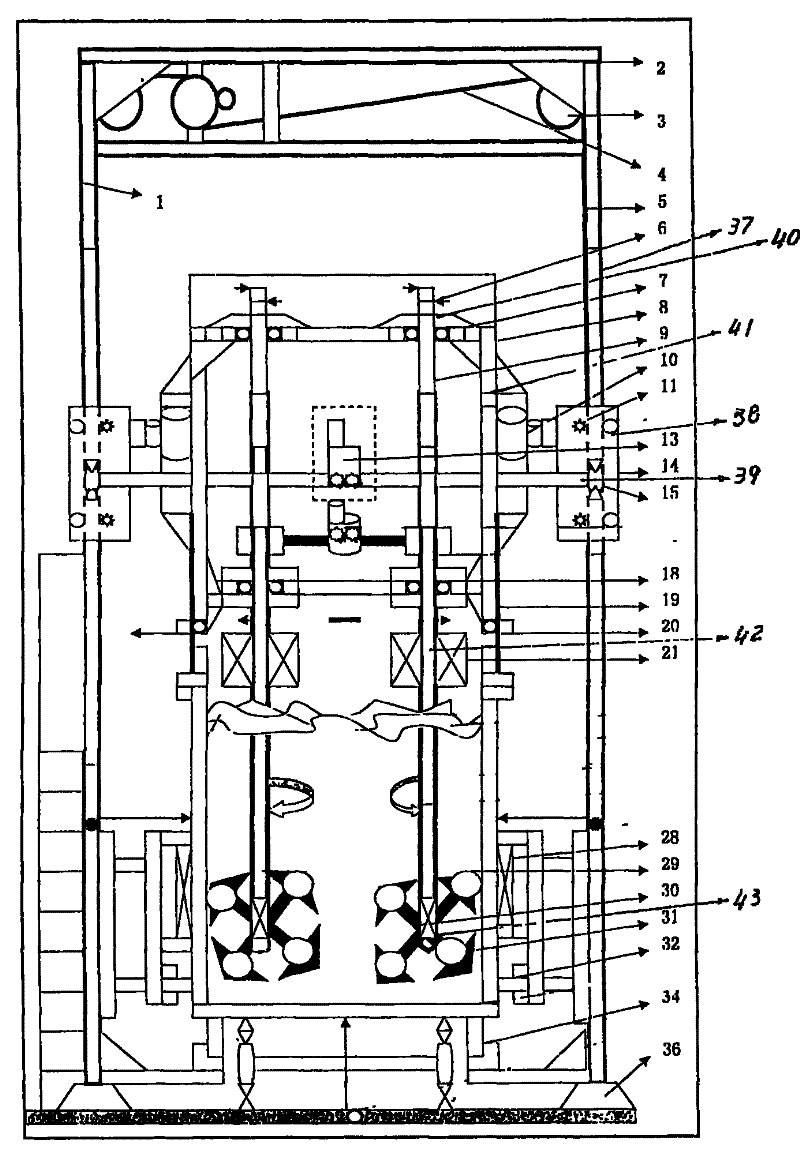

[0011] Example 1: Combining figure 1 , a kind of defreezing device for railway coal handling carriages of the present invention, it is made up of fixed frame mechanism (37) and bridge car mechanism (40), fixed frame mechanism (37) connects bridge car mechanism (40), fixed frame mechanism ( 37) Including beam (2), left pillar (1), right pillar (5), load-bearing pillar cement foundation (36), hoisting winch (3), steel wire rope (4), vertical moving unit (38), horizontal moving unit (39), electromagnetic hammer (32) outside the compartment, electromagnetic hammer (34) and high-frequency eddy current coil (28) at the bottom of the compartment, the left pillar (1) is connected to the beam (2), and the beam (2) is connected to the right pillar (5), The left pillar (1) and the right pillar (5) are respectively connected to the load-bearing pillar cement foundation (36), the hoisting hoist (3) is located below the crossbeam (2), the hoisting hoist (3) is connected to the wire rope (4)...

Embodiment 2

[0015] Example 2: Combining figure 1 , the working process of the present invention is as follows: after the axial-flow plane rotary tool (31) rotates, the axial-flow plane rotary tool (31) cuts the Break the frozen coal around, and finally reach the bottom of the carriage, so that the frozen coal in the carriage is cut apart, and the coal body around the cutter is pushed away, so that the frozen coal in the carriage cannot be divided and broken into a whole, and the relative tension of the overall plane dumping in the carriage is reduced. If it is damaged, the frozen coal is easily dumped by the dumper at 160° to the lower layer of the dumper.

[0016] Since a plurality of drill pipes with axial-flow planar rotary cutters (31) are arranged on the bridge car, and the rotation directions of adjacent drill pipes are opposite, the internal stress rotary cutting method can be used to destroy the external freezing stress of the coal seam in the carriage, and at the same time contai...

Embodiment 3

[0019] Example 3: Binding figure 1 , the mechanical movement process of the present invention: when the coal transport compartment reaches the bottom of the bridge car cover of the thawing device, start the horizontal movement force rack reducer of the bridge car cover, which is designed as a linear rack and pinion mechanism to drive the wheel rail to move horizontally The cover of the bridge car is aligned with the carriage below, start the hoisting hoist and drop it at the designed speed, move the load-bearing rigid frame up and down, move the cover of the bridge car down, and start the drill pipe at the same time, so that the axial flow plane rotary tool rotates at a low speed, and The cover of the bridge car moves downward, and rotates to cut in and push away the coal seam of the car to the bottom of the car. The hoist has a mechanical safety locking device, and the gear bar is designed with mechanical weightlessness and overspeed locking protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com