Multifunctional bunch planter

A kind of seeder, multi-functional technology, applied in the field of multi-functional on-demand seeder, can solve the problems of easy jamming and broken seeds, etc., and achieve the effect of fast seeding speed, convenient use and smooth seeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

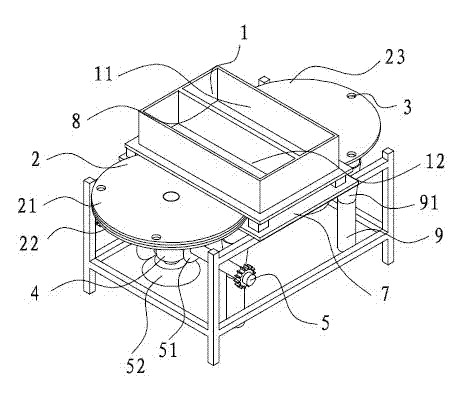

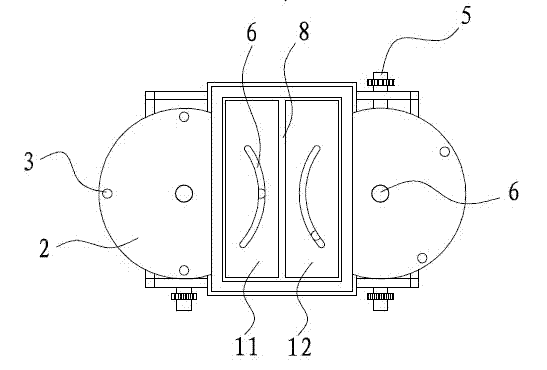

[0025] The multi-functional on-demand seeder includes a sowing unit, the sowing unit includes a trough 1 arranged on the upper part, and a partition 8 is arranged in the middle of the trough 1, and the partition 8 divides the trough into two cavities: the front chamber 11 and the rear chamber 12 , The lower part of the front chamber 11 and the rear chamber 12 are provided with arc-shaped seeding grooves 6 .

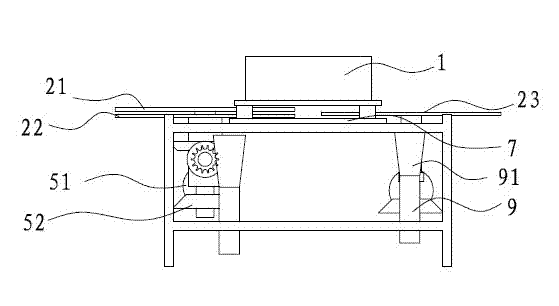

[0026] The bottom of the front chamber 11 is provided with a circular sowing disc 2, the sowing disc 2 is a single sowing disc 23, and the single sowing disc 23 is provided with 4 seeding holes 3 evenly distributed along the perimeter of the sowing disc 2. 2. A baffle plate 7 is provided below; two circular sowing discs 2 are provided below the rear chamber 12, including an upper sowing disc 21 and a lower sowing disc 22 respectively. The sowing hole 3 includes an upper sowing hole and a lower sowing hole. The disc is provided with four upper sowing holes, and the upper s...

Embodiment 2

[0033] The multifunctional on-demand seeder includes two sowing units, the sowing unit includes a trough 1 arranged on the upper part, and a partition 8 is arranged in the middle of the trough 1, and the partition 8 divides the chute into two chambers, the front chamber 11 and the rear chamber 12 The lower part of the front chamber 11 and the rear chamber 12 are provided with arc-shaped seeding grooves 6 .

[0034] A circular sowing disc 2 is respectively arranged under the front cavity 11 and the rear cavity 12. The sowing disc 2 is a single sowing disc 23, and the single sowing disc 23 is drilled with a sowing hole 3. There are four sowing holes 3, and along the The sowing discs 2 are evenly distributed in the circumferential direction, and a baffle 7 is arranged below the sowing discs 2 .

[0035] The drive shaft 4 is arranged below the sowing disc 2, and the driven bevel gear 52 is arranged on the drive shaft 4. The power input shaft 5 is also provided under the sowing dis...

Embodiment 3

[0038]The multi-functional on-demand seeder includes eight sowing units. The sowing unit includes a trough 1 arranged on the upper part. A partition 8 is arranged in the middle of the trough 1. The partition 8 divides the chute into two chambers, the front chamber 11 and the rear chamber 12. The lower part of the front chamber 11 and the rear chamber 12 are provided with arc-shaped seeding grooves 6 .

[0039] The bottom of the front chamber 11 and the rear chamber 12 are respectively provided with two circular sowing discs 2, respectively comprising an upper sowing disc 21 and a lower sowing disc 22, and the sowing hole 3 comprises an upper sowing hole and a lower sowing hole, and the upper sowing disc is provided with There are four upper sowing holes, and the upper sowing holes are evenly distributed along the perimeter of the sowing disc 2, and the lower sowing disc 22 is provided with a lower sowing hole, and the lower sowing hole is arranged directly below the rotation tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com