Flexible rail guide device of hoisting container and dynamic characteristic detection method thereof

A guiding device and flexible guide rail technology, which is applied in the direction of elevators, transportation and packaging, and lifting equipment in mines, etc., can solve the problems of regular battery replacement, strain sensors are easily disturbed by external factors, and inconvenient maintenance, so as to improve stability and The effect of real-time monitoring of service life and dynamic characteristics, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

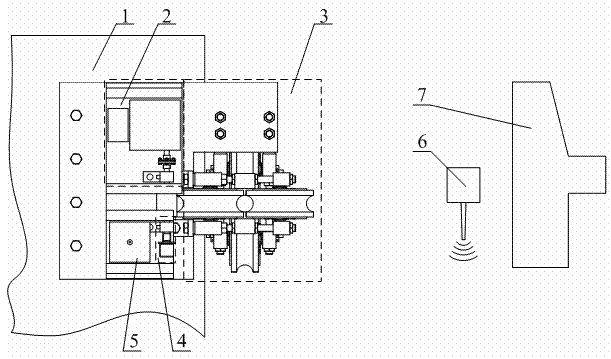

[0029] figure 1 As shown, the flexible rail guiding device of the present invention is mainly composed of a guiding device 3 fixed on the lifting container 1, a wireless receiving device 6 and an industrial computer 7. One side of the guiding device 3 is provided with a power generating device 2, and the other side is provided with There is a detection device 4, and a wireless transmitting device 5 is arranged in the detection device 4.

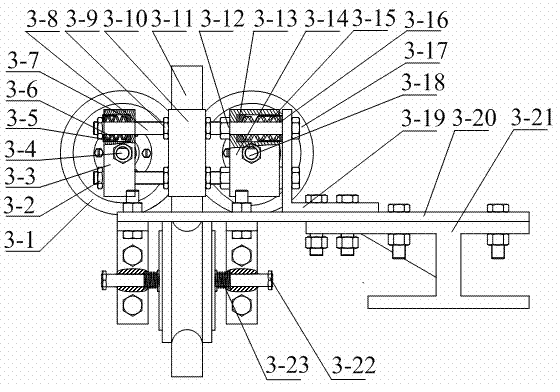

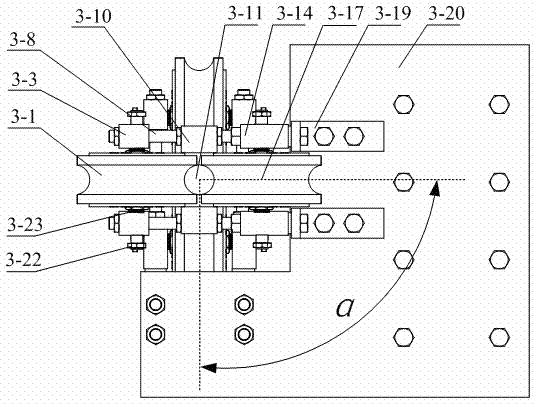

[0030] figure 2Shown, guiding device 3 is mainly made of up and down main guide wheel 3-17, up and down secondary guide wheel 3-1, and up and down main guide wheel 3-17 and up and down secondary guide wheel 3-1 minute form angle ɑ Hugged on both sides of the flexible guide rail 3-11, the angle between the upper main and auxiliary guide wheels and the lower main and auxiliary guide wheels is based on the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com